Production device for preparing epoxypropane through propylene chlorohydrination and use method of production device

A technology for the production of propylene oxide and production equipment, which is applied in the field of production equipment for propylene oxide by the chlorohydrin method, which can solve the problems of not meeting the requirements of environmental protection, serious corrosion of equipment, difficult disposal of waste water and waste residue, etc., and achieve energy saving and raw material utilization High efficiency, easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

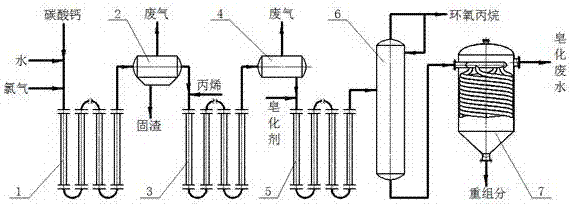

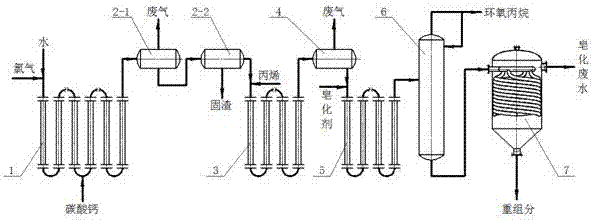

[0034] The device used in embodiment 1 comprises: hypochlorous acid reactor 1, gas-liquid-solid three-phase separator 2, chloroalcoholization reactor 3, gas-liquid separator 4, saponification reactor 5, saponification separation tower 6, liquid-liquid separator 7. Connecting pipelines and intermediate tanks between equipment, gas conveying devices, liquid conveying devices, control and display instruments and accessories. Wherein the hypochlorous acid reactor 1, the chloroalcoholization reactor 3, and the saponification reactor 5 are tubular reactors composed of straight pipes and curved pipes, and chemical fillers are arranged in the straight pipe part; the liquid-liquid separator 7 is provided with 4 in the vertical cylinder. A continuous settling separator with a spiral coil. The hypochlorous acid reactor 1 is provided with chlorine gas, water and calcium carbonate inlet pipelines, the outlet of the hypochlorous acid reactor 1 is connected with the inlet of the gas-liquid-s...

Embodiment 2

[0036] Embodiment 2 is substantially the same as Example 1, except that the straight pipe part of the hypochlorous acid reactor 1 used, the chloroalcoholization reactor 3, and the saponification reactor 5 is a commercially available static mixer, and the saponification agent used is hydrogen sodium oxide.

Embodiment 3

[0038] Embodiment 3 is basically the same as Embodiment 1, except that a part of the saponification wastewater is discharged from the system, and a part is returned to the hypochlorous acid reactor 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com