A kind of synthetic method of high regularity polybutene-1

A synthesis method and a high-specificity technology are applied in the field of synthesis of polybutene-1 of regularity, and can solve the problems of long polybutene-1 crystal transformation period, low isotacticity of polybutene-1, and the like. Improve the effect of long crystal transformation period, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

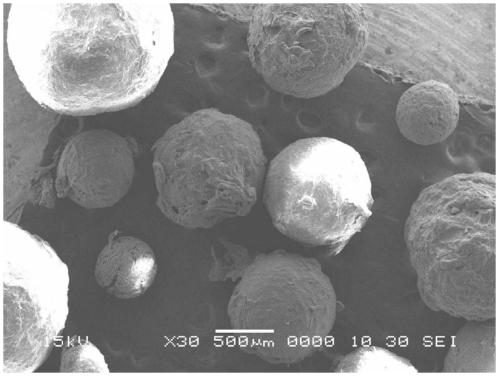

[0040] In a 0.25L stainless steel autoclave, after the system was replaced three times with nitrogen, 0.81ml of 1mol / L triethylaluminum solution was added successively under nitrogen protection (the solvent is n-hexane, the same as in the following examples), diphenyl dimethoxy Silane 0.009mmol, methyl n-butyl ether 0.018mmol, TiCl 4 / MgCl 2 .ID / SiO 2 Supported Ziegler-Natta catalyst 5mg (0.0027mmol titanium), liquid phase propylene 70g, pre-polymerized at 50°C for 10min. After the reaction, vacuumize, add butene-1 monomer 95g, hydrogen 0.0035MPa, polymerize at a constant temperature at 35°C for 5h, and flash evaporate to remove unreacted monomer to obtain polybutene-1 powder with a particle size of 0.01-3mm. The molar ratio of the aluminum in the cocatalyst to the titanium in the main catalyst is 300, the molar ratio of the aluminum in the cocatalyst to the silicon in the composite external electron donor is 90, diphenyldimethoxysilane and methyl n-butyl ether The molar ra...

Embodiment 2

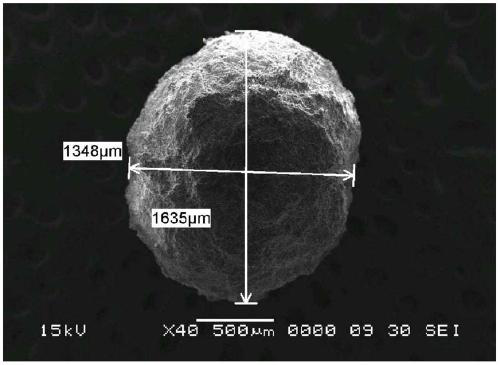

[0042] Compared with Example 1, except that the molar ratio of diphenyldimethoxysilane and methyl n-butyl ether in the composite external electron donor was changed to 1:7, the rest of the operation and reaction conditions remained unchanged, and the obtained particle size was 1348μm×1635μm polybutene-1 powder (such as figure 1 and figure 2 ). Catalyst activity is 6101g polybutene-1 / g main Cat, and isotactic polymer content (heptane soluble matter accounts for the percentage of heptane soluble matter and ether soluble matter summation) is 97.6%, molecular weight distribution is 6.3, poly The propylene content is 5.0%, the semi-crystallization time t of polybutene-1 powder crystallization at room temperature 1 / 2 =4.4h (the half-crystallization time t of the polybutene-1 homopolymer of measurement 1 / 2 = 25.4h). The crystal melting peak temperatures of the polymers measured by differential scanning calorimetry (DSC) were 124.2°C and 162.9°C, respectively.

Embodiment 3

[0044] Compared with Example 1, except that the molar ratio of diphenyldimethoxysilane to methyl n-butyl ether in the composite external electron donor was changed to 1:8, the rest of the operation and reaction conditions remained unchanged. Catalyst activity is 6131g polybutene-1 / g main Cat, and isotactic polymer content (heptane soluble matter accounts for the percentage of heptane soluble matter and ether soluble matter summation) is 98.1%, molecular weight distribution is 5.9, poly The propylene content is 4.8%, the semi-crystallization time t of polybutene-1 powder crystallization at room temperature 1 / 2 =4.5h (the half-crystallization time t of the polybutene-1 homopolymer of measurement 1 / 2 = 25.4h). The crystal melting peak temperatures of the polymers measured by differential scanning calorimetry (DSC) were 123.9°C and 162.6°C, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com