A kind of preparation method of high regularity polybutene-1 powder

A high-specificity, polybutene technology, applied in the field of polybutene-1 powder and its preparation, can solve the problems of long polybutene-1 crystal transformation period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1), preparation of catalytic components

[0048] (1) Vacuumize a 250ml three-necked flask, replace it with argon three times, add 3g (0.032mol) of anhydrous magnesium chloride under an argon atmosphere, 85ml (0.44mol) of inert solvent n-decane, 0.4g (0.0027mol) of phthalic anhydride mol), 35ml (0.22mol) of isooctyl alcohol, the system was heated up to 100°C for 2h, and naturally cooled to room temperature under the protection of argon to obtain alcohol and compound.

[0049] (2) Vacuumize the 500ml five-neck bottle, replace it with argon for 3 times, and add 50ml TiCl 4 , cooling down to -30°C--20°C in an ice-salt bath, drop the above-prepared alcohol compound into the five-necked bottle, and complete the dropwise addition within 2 hours.

[0050] (3) heat up to 80°C, keep warm for 2h,

[0051] (4) Remove the upper liquid after standing for 20 minutes. At this time, the temperature of the system is basically room temperature. Add 50ml of TiCl at this temperature 4 C...

Embodiment 2

[0057] (1), preparation of catalytic components

[0058] (1) Vacuumize a 250ml three-necked flask, replace it with argon three times, add 3g (0.032mol) of anhydrous magnesium chloride under an argon atmosphere, 85ml (0.44mol) of inert solvent n-decane, 0.4g (0.0027mol) of phthalic anhydride mol), 35ml (0.22mol) of isooctyl alcohol, the system was heated up to 100°C for 2h, and naturally cooled to room temperature under the protection of argon to obtain alcohol and compound.

[0059] (2) Vacuumize the 500ml five-neck bottle, replace it with argon for 3 times, and add 50ml TiCl 4 , cooling down to -30°C--20°C in an ice-salt bath, drop the above-prepared alcohol compound into the five-necked bottle, and complete the dropwise addition within 2 hours.

[0060] (3) heat up to 80°C, keep warm for 2h,

[0061] (4) Remove the upper liquid after standing for 20 minutes. At this time, the temperature of the system is basically room temperature. Add 50ml of TiCl at this temperature 4 C...

Embodiment 3

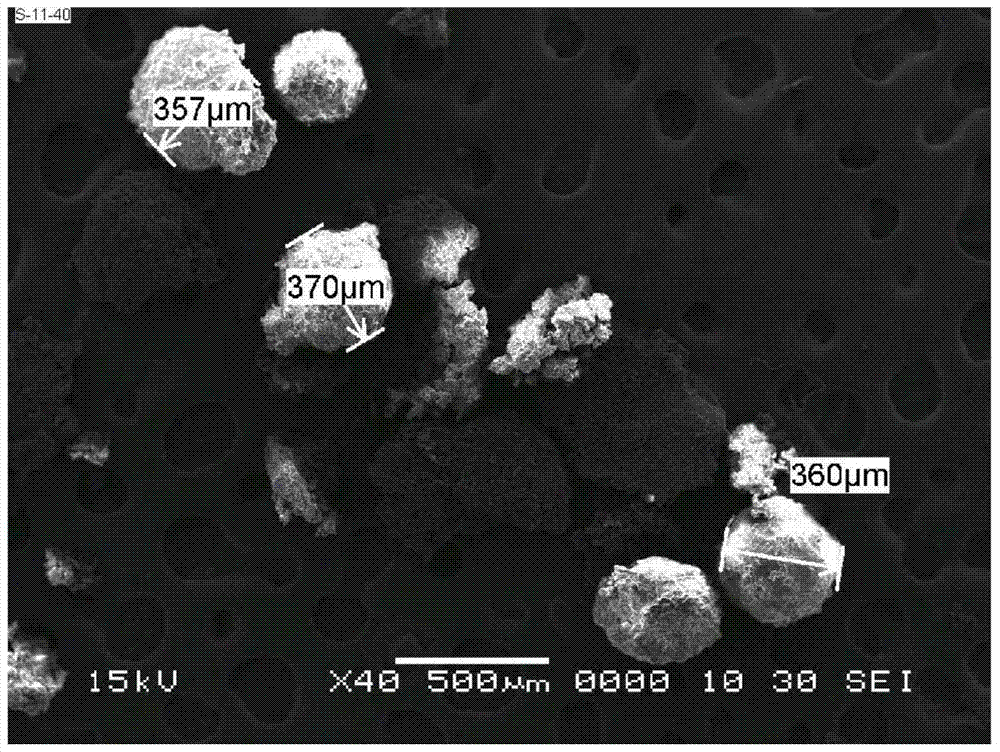

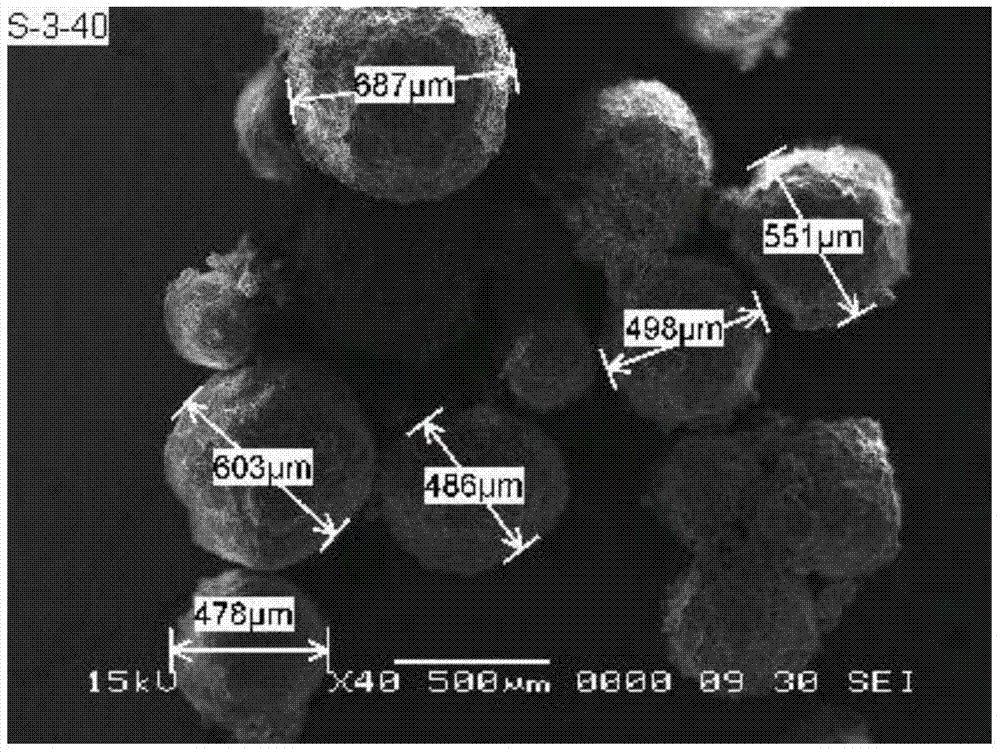

[0067] In a 2L stainless steel autoclave, after the system was replaced with nitrogen three times, 2.3ml of 1mol / L triethylaluminum solution was added successively under nitrogen protection (the solvent is n-hexane, the same as in the following examples), methylcyclohexyldimethoxy 0.075 mmol of silane, 20 mg of the supported Ziegler-Natta catalyst prepared in Example 1 (0.0076 mmol of titanium), 25 mg of lanthanum stearate and 25 mg of stearic acid, 473 g of propylene in liquid phase, pre-polymerized at 50° C. for 10 min. After the reaction, empty the propylene in the kettle, add 150g of butene-1 monomer, hydrogen 0.10MPa, polymerize at a constant temperature of 25°C for 8h, remove unreacted monomer by flash evaporation, and obtain polybutene-1 with a particle size of 0.1-3mm powder (such as figure 1 ), the catalyst activity is 4599g / g Cat, and the bulk density is 0.30g / cm 3 , the isotacticity of the polymer is 95.3%, the molecular weight distribution is 6.8, the polypropylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com