Preparation method and application of water treatment agent

A technology of water treatment and chemicals, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of increased sludge treatment cost, high price, and increased sludge volume, etc. Achieve the effects of avoiding the use of hazardous chemicals, reducing production costs, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Treatment of high fluoride and high arsenic drinking water sources

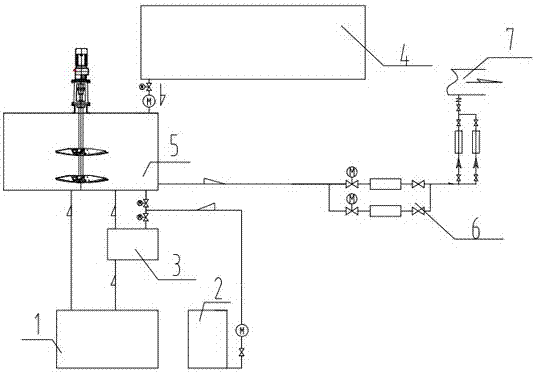

[0040] (1) Add 15 parts of bentonite from the outlet of silo 1, and 0.45 parts of organic modifier PDMDAAC (polydimethyldiallyl ammonium chloride) in organic modifier storage tank 2 to the SLG type continuous powder Organic modification is carried out in the surface modification machine 3 to obtain an organic modified powder;

[0041] (2) 100 points of polyferric sulfate (solid content 45%) solution is squeezed into the reaction tank 5 from the drug storage tank 4, and then 15 parts of organically modified powders are sent into the reaction tank from the modification machine 3 ( Hydrophobic adsorption part), another 15 parts of bentonite are directly sent to the reaction tank (hydrophilic adsorption part) from the outlet of feed bin 1. Mix and stir for inorganic modification to obtain water treatment chemicals;

[0042] (3) The water treatment agent is put into the process pipeline through...

Embodiment 2

[0044] Embodiment 2: Treatment of high algae and high turbidity reservoir water

[0045] (1) Add 50 parts of diatomite from silo 1, cationic PAM in organic modifier storage tank 2 to PSC type powder surface modifier 3 for organic modification, and the dosage is the quality of diatomite 2% of the number of parts to obtain diatomite after organic modification;

[0046] (2) 100 parts of polyaluminum chloride (30% solid content) solution is injected into the reaction tank 5 from the drug storage tank 4; for enhancing the turbidity removal effect, the cationic PAM is injected from the organic modifier storage tank 2 Enter the reaction tank 5, the mass fraction is 0.5% of the polyaluminium chloride solution quality, the reaction tank is stirred, and then 50 parts of diatomite after organic modification are sent into the reaction tank 5 from the modification machine 3, and stirred to obtain the water treatment agent ;

[0047] (3) Put the water treatment agent into the process pipe...

Embodiment 3

[0049] Embodiment 3: Treatment of low-temperature and low-turbidity POPS polluted reservoir water

[0050] (1) 80 parts of attapulgite are added to the PSC type powder surface modifier 3 from silo 1, and the chitosan in the organic modifier storage tank 2 is organically modified, and the organic modifier is a consumption of 2% of the attapulgite mass fraction;

[0051] (2) 100 parts of polyferric chloride (solid content 50%) solutions are squeezed into reaction tank 5 from medicine storage tank 4; Into the reaction tank 5 to stir, carry out the inorganic modification of attapulgite, and obtain the water treatment agent;

[0052] (3) After measuring the water treatment agent, the dosing device 6 is put into the process pipeline, and enters the next step of the water treatment process 7, and the dosage is 10L / KT.

[0053] In Example 3, the ferric chloride mixed gel has good settling property and good effect of removing organic matter; attapulgite CEC has high cation exchange c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com