Nitrogen-doped hollow carbon nanometer material preparation method

A carbon nanomaterial and nanomaterial technology, applied in the field of nanomaterial preparation, can solve the problems of limiting the wide application of nitrogen-doped hollow carbon materials, polluting the environment, low yield, etc., and achieving excellent electrochemical performance, excellent cycle stability, high Effect of magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a nitrogen-doped hollow carbon nanomaterial, comprising:

[0028] (1) Clean the nickel foam substrate in acetone, ethanol and distilled water in sequence. Then soak it in 5mmol·L -1 10min in ethanol solution of zinc nitrate, take it out and quickly dry it at 100°C, repeat 3-5 times. Finally, the substrate was heated to 350°C in air for 30 minutes to decompose zinc nitrate to obtain a ZnO seed layer;

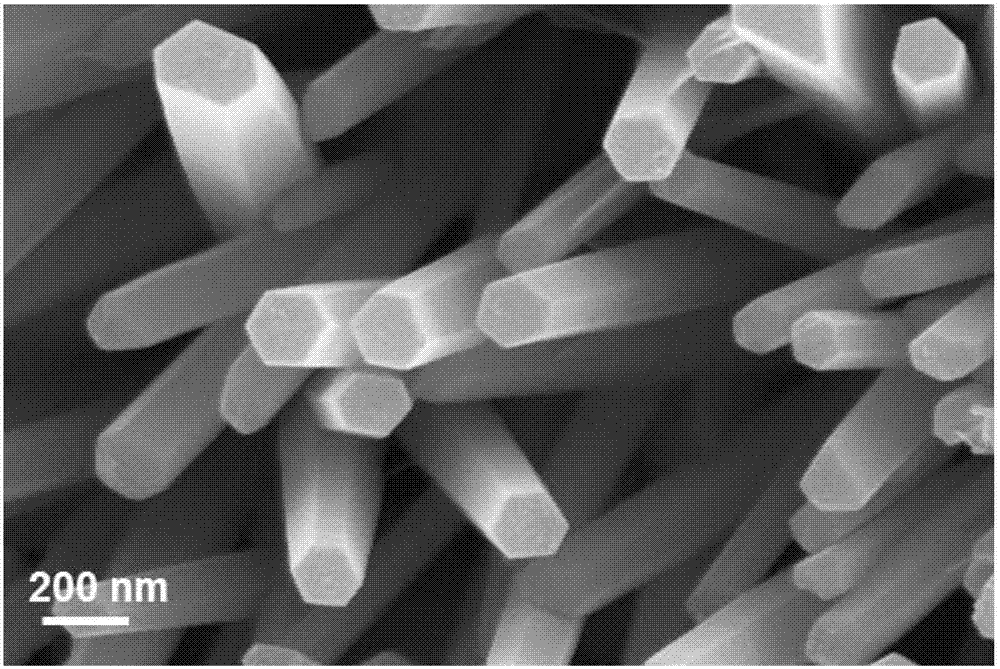

[0029] (2) Prepare 30mmol L in a polytetrafluoroethylene reactor -1 80 mL of zinc nitrate aqueous solution, slowly drop 3 mL of concentrated ammonia water into it, and after mixing evenly, put the substrate with ZnO seed layer prepared in step (1) vertically into the reaction kettle. Finally, the reaction kettle was placed in an oven, and reacted at 90° C. for 6 hours. After the reaction, it was washed and dried to obtain a ZnO nanorod array template;

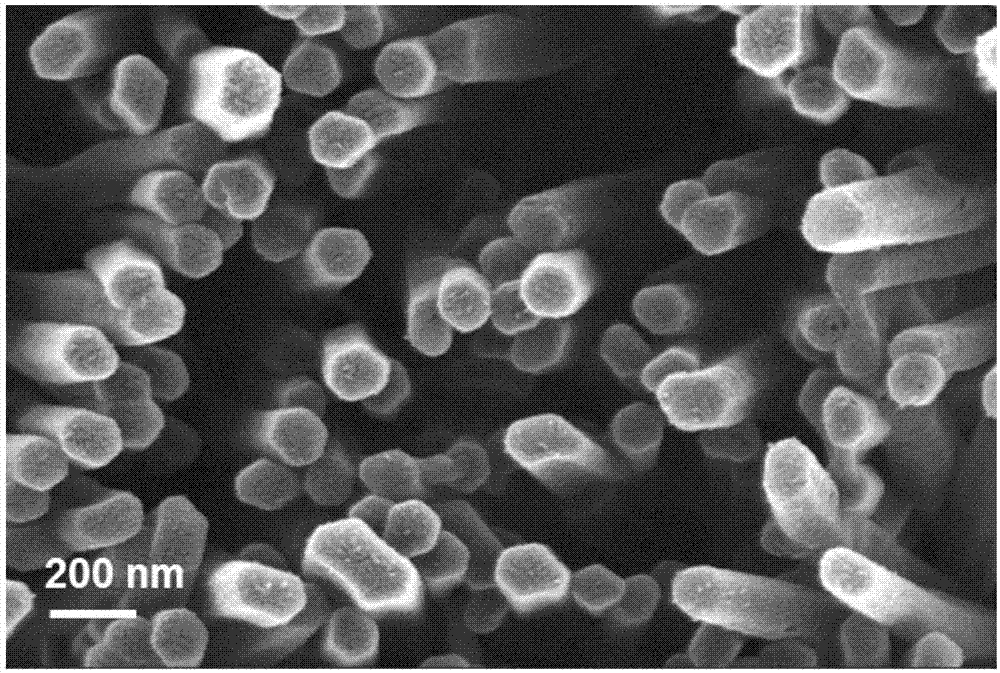

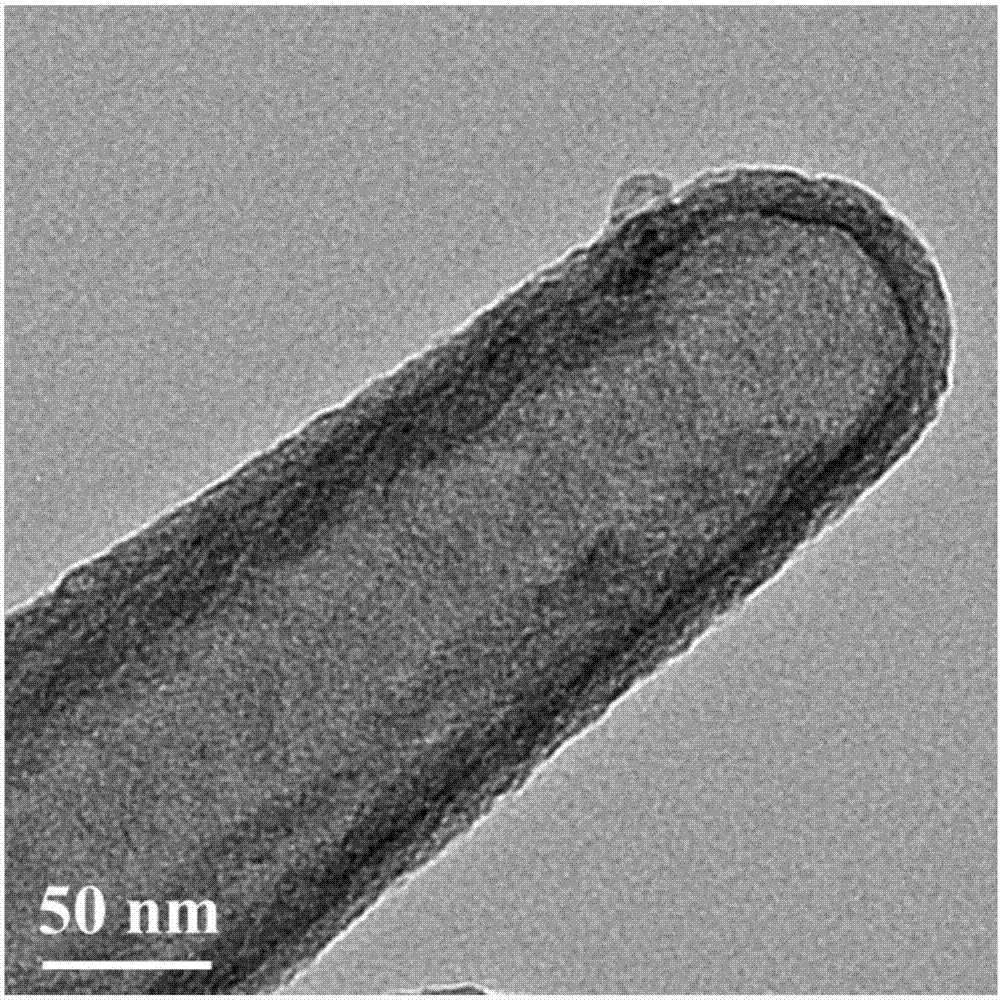

[0030] (3) Take 0.20g triaminotrinitrobenzene (TATB) and spread it on the bottom of the porcel...

Embodiment 2

[0032] A method for preparing a nitrogen-doped hollow carbon nanomaterial, comprising:

[0033] (1) Clean the carbon cloth substrate in acetone, ethanol and distilled water in sequence. Then soak it in 5mmol·L -1 10min in ethanol solution of zinc nitrate, take it out and quickly dry it at 100°C, repeat 3-5 times. Finally, the substrate was heated to 350°C in air for 30 minutes to decompose zinc nitrate to obtain a ZnO seed layer;

[0034] (2) Prepare 30mmol L in a polytetrafluoroethylene reactor -1 80 mL of zinc nitrate aqueous solution, slowly drop 3 mL of concentrated ammonia water into it, and after mixing evenly, put the substrate with ZnO seed layer prepared in step (1) vertically into the reaction kettle. Finally, the reaction kettle was placed in an oven, and reacted at 90° C. for 6 hours. After the reaction, it was washed and dried to obtain a ZnO nanorod array template;

[0035] (3) Take 0.25g of triaminotrinitrobenzene (TATB) and spread it on the bottom of the po...

Embodiment 3

[0037] A method for preparing a nitrogen-doped hollow carbon nanomaterial, comprising:

[0038] (1) Clean the carbon cloth substrate in acetone, ethanol and distilled water in sequence. Then soak it in 5mmol·L -1 10min in ethanol solution of zinc nitrate, take it out and quickly dry it at 100°C, repeat 3-5 times. Finally, the substrate was heated to 350°C in air for 30 minutes to decompose zinc nitrate to obtain a ZnO seed layer;

[0039] (2) Prepare 30mmol L in a polytetrafluoroethylene reactor -1 80 mL of zinc nitrate aqueous solution, slowly drop 3 mL of concentrated ammonia water into it, and after mixing evenly, put the carbon cloth substrate with ZnO seed layer prepared in step (1) vertically into the reaction kettle. Finally, the reaction kettle was placed in an oven, and reacted at 90° C. for 6 hours. After the reaction, it was washed and dried to obtain a ZnO nanorod array template;

[0040] (3) Spread 0.25g of triaminotrinitrobenzene (TATB) on the bottom of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com