Preparation method of vanadium dioxide nano material and application in rechargeable magnesium battery

A vanadium dioxide and nanomaterial technology, applied in the field of electrochemistry, can solve the problems of large discharge specific capacity decay and short cycle life, and achieve the effects of good magnesium storage electrochemical performance, excellent rate performance, and good electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

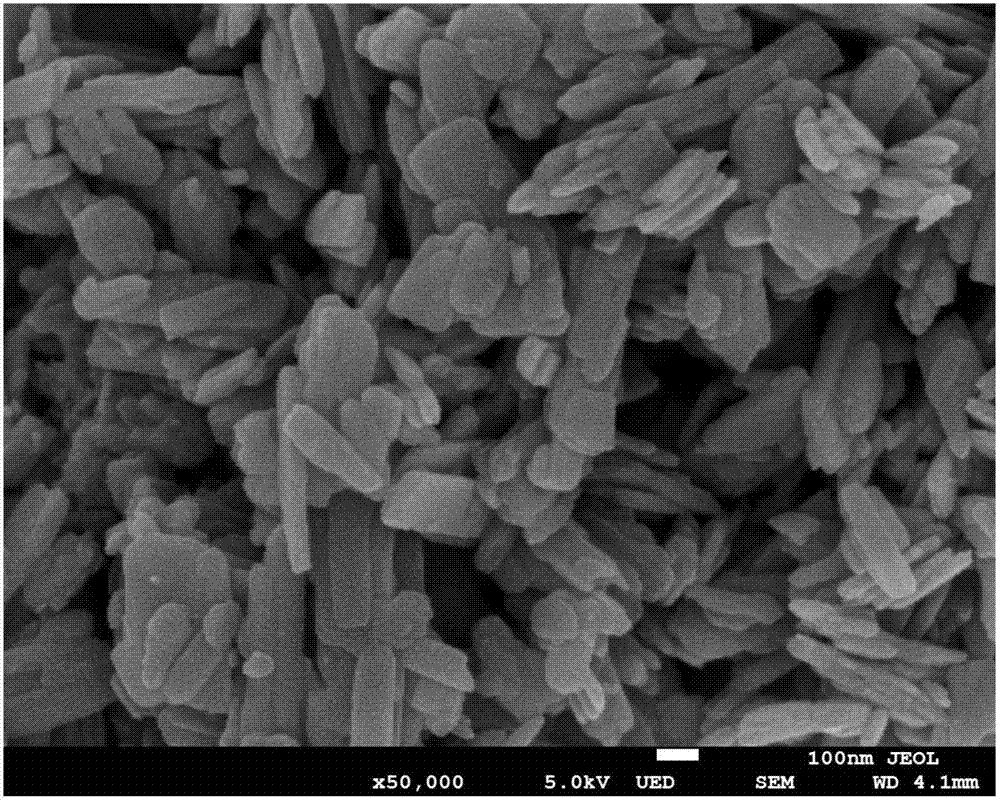

[0033] Accurately weigh and weigh 0.364g V 2 o 5 and 0.630g of citric acid were dissolved in 66mL of distilled water, stirred at 40°C for 22h to obtain a grass green suspension, which was transferred to a 100mL high-pressure hydrothermal reactor lined with polytetrafluoroethylene, and heated at 180°C Keep it warm for a period of time (from room temperature to 180 ° C, heating rate 5 ° C / min), then naturally cool to room temperature, collect the solid by suction filtration, and wash with absolute ethanol and distilled water several times in sequence to obtain a blue-black solid, and finally in Dry at 100°C for 12 hours under vacuum to obtain blue-black vanadium dioxide powder. The prepared vanadium dioxide is phase B, with high purity and good crystallinity; its microscopic appearance is nanosheets with a length of 30-300nm and a width of 30-200nm, see figure 1 The SEM.

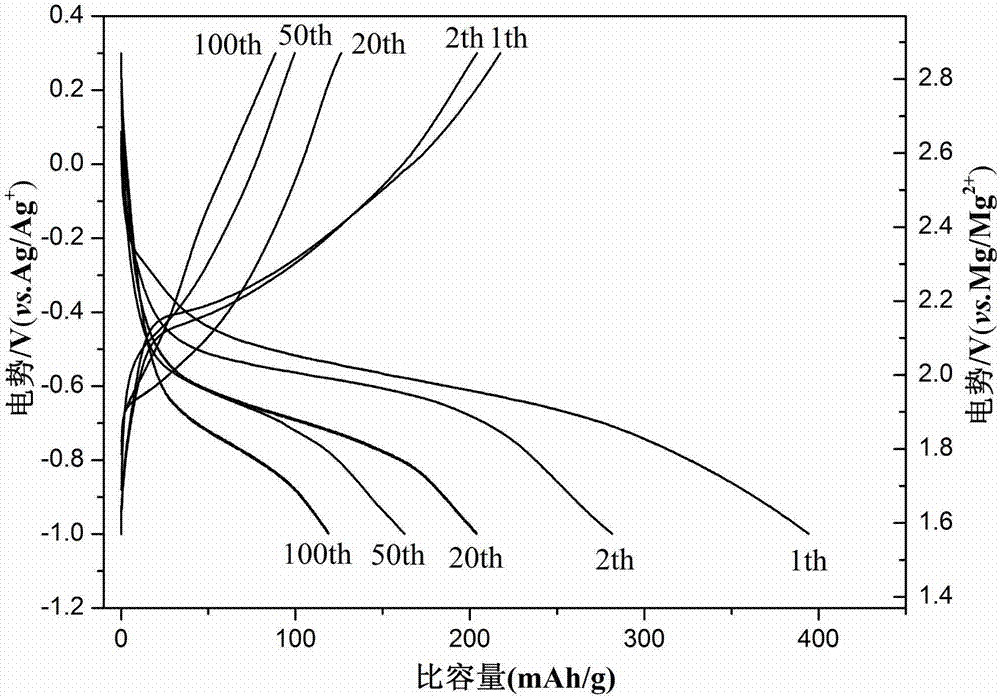

[0034] The vanadium dioxide powder material is made into magnesium rechargeable battery positive pole ...

Embodiment 2

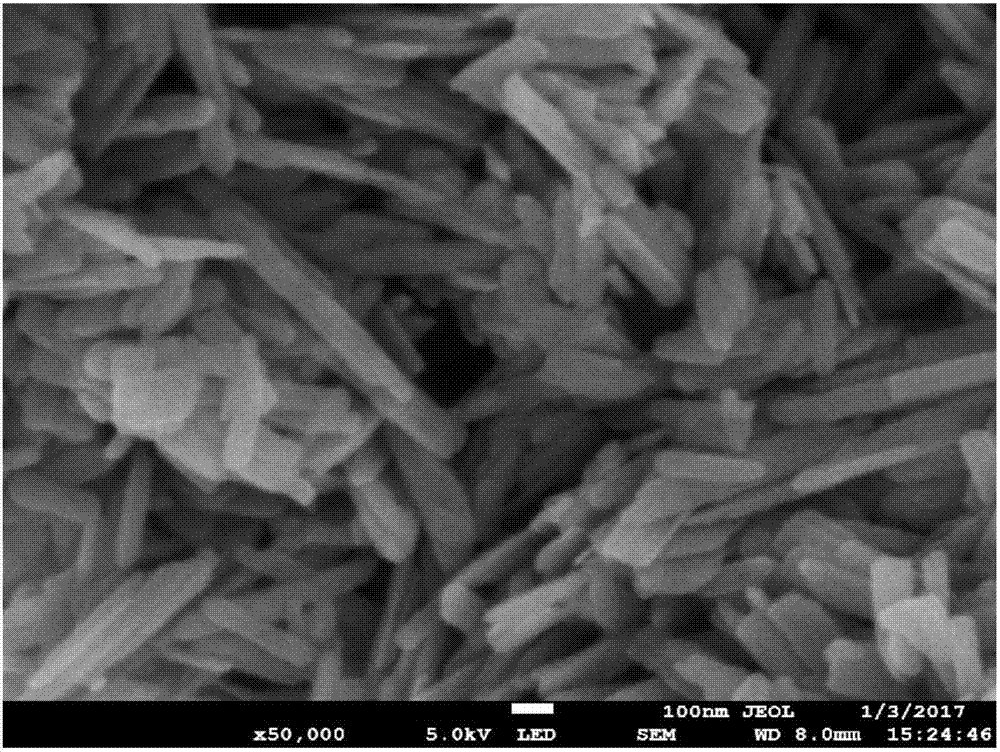

[0037] Accurately weigh and weigh 0.364g V 2 o 5 , 0.630g of citric acid and 0.058g of sodium lauryl sulfate were dissolved in 66mL of distilled water, and stirred at a constant temperature at 40°C for 22h to obtain a grass-green suspension liquid, which was transferred to 100mL of high-pressure water lined with polytetrafluoroethylene In a thermal reaction kettle, keep warm at 180°C for a period of time (from room temperature to 180°C, heating rate 5°C / min), then naturally cool to room temperature, collect the solid by suction filtration, and wash with absolute ethanol and distilled water several times, A blue-black solid was obtained, and finally dried under vacuum at 100° C. for 12 hours to obtain a blue-black vanadium dioxide powder. The obtained vanadium dioxide is phase B, with high purity and good crystallinity, see Figure 4 XRD; its microscopic appearance is a nanorod with a length of 600-800nm and a width of 50-100nm, see image 3 The SEM.

[0038] Vanadium dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com