Film for oled encapsulation, manufacturing method thereof, and method for encapsulating oled using the film

A technology of film and water vapor, which is applied in semiconductor/solid-state device manufacturing, coating, electric solid-state devices, etc., can solve the problems of material cracking in OLED, bubble retention, affecting OLED performance and life, etc., to improve performance and prolong OLED The effect of service life and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0064] Hereinafter, the content disclosed by the present invention will be specifically described using specific embodiments. However, the content disclosed in the present invention is not limited to the following examples.

Embodiment 1

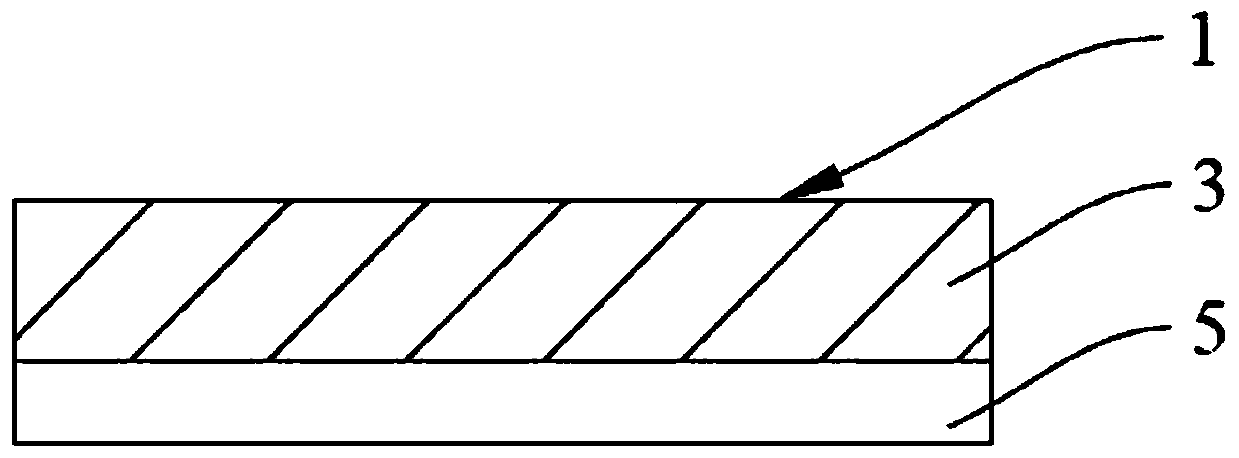

[0067] Embodiment 1. OLED packaging film 1

[0068] Butadiene-acrylonitrile epoxy resin (Hypro 1300× sold by Emerald Performance Material, U.S.) of 68g of triglycidyl isocyanurate (TEPIC-S sold by Nissan Chemical), 24g of epoxy-terminated butadiene-acrylonitrile epoxy resin 44ETBN), 8g of phenoxy resin (H360 sold by Japan Ink Chemical Industry Co., Ltd. DIC), 6g of dicyandiamide (sold by Germany Degussa), bis (dimethyl urea) compound (sold by Japan SANAPRO company U-CAT 3513N), photoinitiator (CPI-200S sold by Japanese SANAPRO company) and 1g of the modified nano-montmorillonite D2000 / MMT of the preparation example are mixed evenly, and the mixture is epoxy resin-modified nano-montmorillonite slurry.

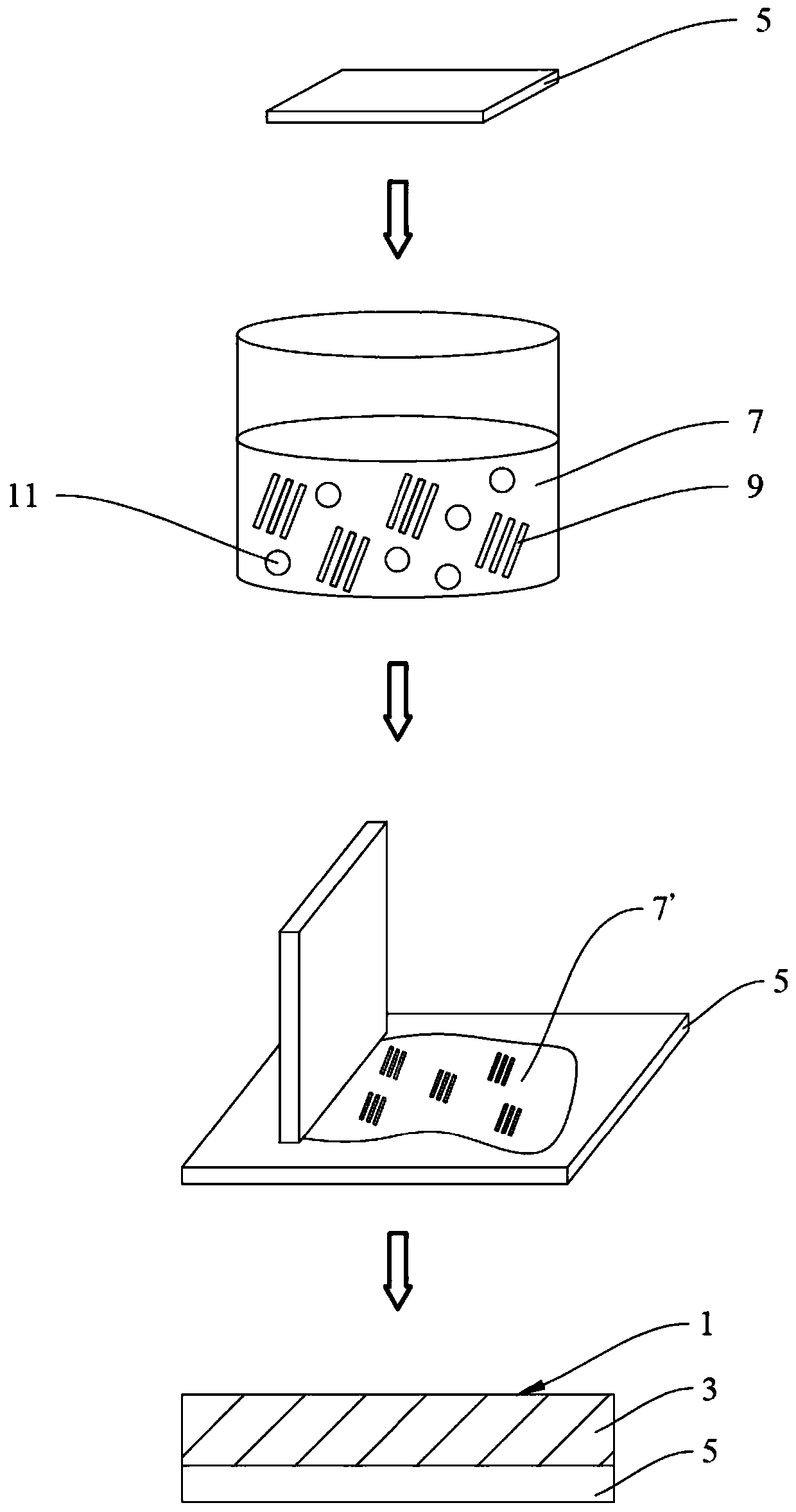

[0069] The epoxy resin-modified nano-montmorillonite slurry was precision-coated onto a polyethylene terephthalate release sheet to form a wet film with a thickness of 60 μm, and baked in a continuous oven at 90°C for 10 Minutes, and at the same time, ultraviolet light can be ...

Embodiment 2

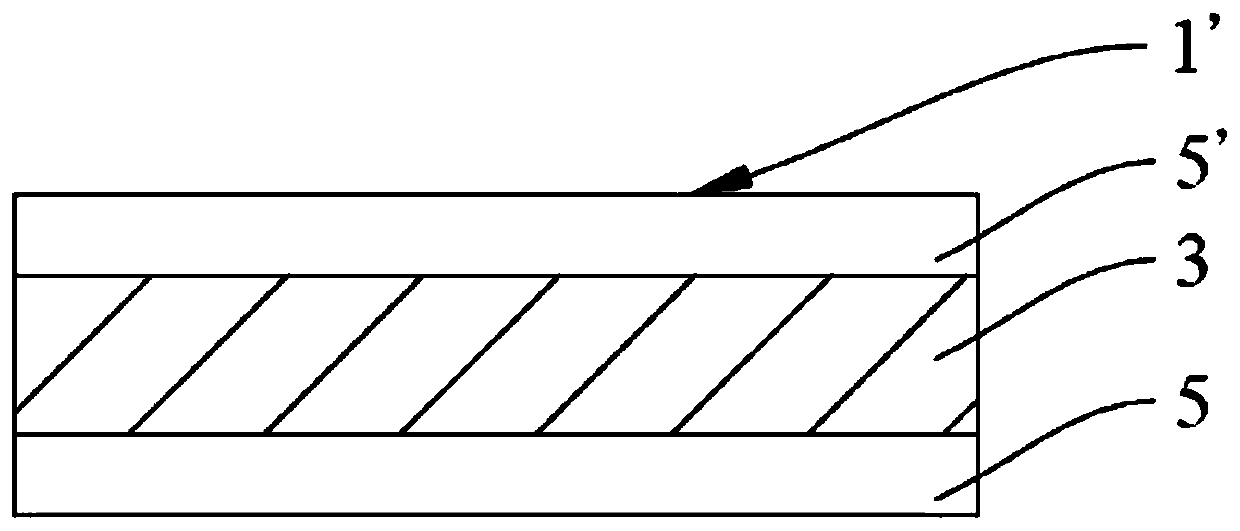

[0070] Example 2. OLED encapsulation film 2

[0071] The manufacturing steps are the same as in Example 1, as shown in Table 1, the only difference is that the modified nano-montmorillonite D2000 / MMT of the preparation example added to the epoxy resin / modified nano-montmorillonite slurry is 2 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com