Organic glass material for medical glass bottles, and preparation method thereof

A plexiglass and glass bottle technology, applied in the field of polymer materials, can solve the problems of no sterilization effect, expensive components and raw materials, complex molding process, etc., to improve smooth transparency, excellent antibacterial and sterilization performance, mechanical Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

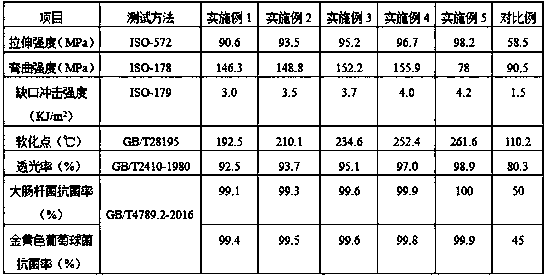

Examples

Embodiment 1

[0031] A plexiglass material for medical glass bottles, which is prepared by free radical polymerization from the following raw materials in parts by weight: 5 parts of methyl methacrylate, 1 part of ditrimethylsilylated vinyl phosphate, 1 part of vinyl ethylene carbonate 2 parts of ester, 1 part of zinc 2-vinylbenzenesulfonate, 0.2 part of surface modified glass fiber powder, 0.1 part of vinyl modified nano-silica, 0.05 part of sodium dodecylbenzenesulfonate, 0.05 part of benzoin ether;

[0032] The preparation method of the zinc 2-vinylbenzenesulfonate comprises the steps of: dissolving 20 g of 2-vinylbenzenesulfonic acid in 50 g of water, and adding 10 g of zinc hydroxide therein, stirring and reacting in an ice-water bath for 2 hours , and then filtered and rotary evaporated to obtain zinc 2-vinylbenzenesulfonate.

[0033] The preparation method of the surface-modified glass fiber powder comprises the steps of: dispersing 30 g of glass fiber powder in 80 g of ethanol, and ...

Embodiment 2

[0040]A plexiglass material for medical glass bottles, which is made by free radical polymerization of the following raw materials in parts by weight: 6 parts of methyl methacrylate, 2 parts of ditrimethylsilylated vinyl phosphate, 2 parts of vinyl ethylene carbonate 3 parts of ester, 1 part of zinc 2-vinylbenzenesulfonate, 0.3 part of surface modified glass fiber powder, 0.2 part of vinyl modified nano-silica, 0.07 part of polyoxypropylene polyvinyl glyceryl ether, 0.07 part of benzoin isopropyl ether ;

[0041] The preparation method of zinc 2-vinylbenzenesulfonate comprises the steps of: dissolving 23 g of 2-vinylbenzenesulfonic acid in 60 g of water, and adding 10 g of zinc hydroxide to it, stirring and reacting in an ice-water bath for 2.5 hours , and then filtered and rotary evaporated to obtain zinc 2-vinylbenzenesulfonate.

[0042] The preparation method of the surface-modified glass fiber powder comprises the steps of: dispersing 35 g of glass fiber powder in 95 g of...

Embodiment 3

[0049] A plexiglass material for medical glass bottles, which is made by free radical polymerization of the following raw materials in parts by weight: 7 parts of methyl methacrylate, 2 parts of bistrimethylsilylated vinyl phosphate, vinyl ethylene carbonate 3 parts of ester, 2 parts of zinc 2-vinylbenzenesulfonate, 0.4 part of surface modified glass fiber powder, 0.1 part of vinyl modified nano-silica, 0.08 part of nonylphenol polyoxyethylene ether, 0.08 part of benzoin butyl ether;

[0050] The preparation method of zinc 2-vinylbenzenesulfonate comprises the steps of: dissolving 25 g of 2-vinylbenzenesulfonic acid in 71 g of water, and adding 10 g of zinc hydroxide thereto, stirring and reacting in an ice-water bath for 3 hours , and then filtered and rotary evaporated to obtain zinc 2-vinylbenzenesulfonate.

[0051] The preparation method of the surface-modified glass fiber powder comprises the steps of: dispersing 41 g of glass fiber powder in 100 g of ethylene glycol, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com