Method for preparing meat preservative film from shrimp and crab shells

A technology of shrimp and crab shells and fresh-keeping film, which is applied in the direction of preservation of meat/fish with chemicals, application, food ingredients as anti-microbial preservation, etc., which can solve the problems of unsatisfactory fresh-keeping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

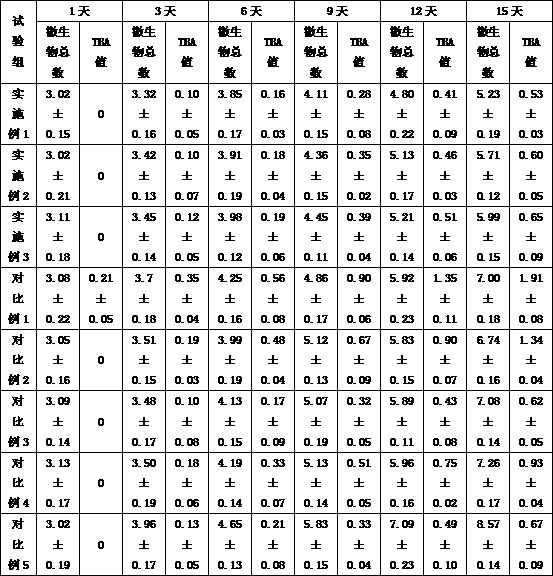

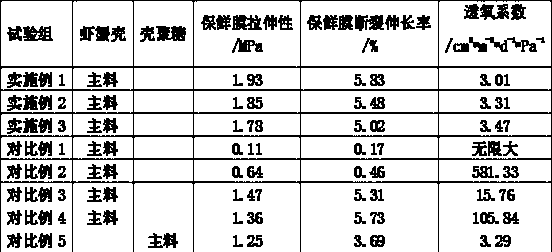

Examples

Embodiment 1

[0024] A kind of method that utilizes shrimp and crab shell to prepare meat preservation film, it goes through the following process steps:

[0025] (1) Raw material pretreatment

[0026] S1. Preparation of chitin nanoparticles: Weigh dried shrimp and crab shells, add distilled water, wherein the weight ratio of shrimp and crab shells to distilled water is 1:4, then put them into a muffle furnace at 180°C, and conduct constant temperature hydrothermal treatment for 12 hours. And the muffle furnace is provided with a nitrogen working environment by a nitrogen filling device. The conditions of the nitrogen working environment of the muffle furnace are: nitrogen pressure 5MPa, flow rate 12kg / h; Conditions: power 15KHz, nitrogen environment; after crushing, add polyphosphate, the amount of polyphosphate added is 2.5% of the total weight of shrimp and crab shells and distilled water, homogenize with a homogenizer for 12 minutes, let stand for 4 minutes, remove the precipitate, The...

Embodiment 2

[0032] A kind of method that utilizes shrimp and crab shell to prepare meat preservation film, it goes through the following process steps:

[0033] (1) Raw material pretreatment

[0034] S1. Preparation of chitin nanoparticles: Weigh dried shrimp and crab shells, add distilled water, wherein the weight ratio of shrimp and crab shells to distilled water is 1:3, then put them into a muffle furnace at 150°C, and conduct constant temperature hydrothermal treatment for 10 hours. And the muffle furnace is provided with a nitrogen working environment by a nitrogen filling device. The conditions of the nitrogen working environment of the muffle furnace are: nitrogen pressure 4MPa, flow rate 10kg / h; Treatment conditions: power 10KHz, nitrogen environment; add polyphosphate after crushing treatment, the amount of polyphosphate added is 1% of the total weight of shrimp and crab shells and distilled water, homogenize with a homogenizer for 10 minutes, let stand for 3 minutes, and remove ...

Embodiment 3

[0040] A kind of method that utilizes shrimp and crab shell to prepare meat preservation film, it goes through the following process steps:

[0041] (1) Raw material pretreatment

[0042]S1. Preparation of chitin nanoparticles: Weigh dried shrimp and crab shells, add distilled water, wherein the weight ratio of shrimp and crab shells to distilled water is 1:5, then put them in a muffle furnace at 200°C, and conduct constant temperature hydrothermal treatment for 15 hours. And the muffle furnace is provided with a nitrogen working environment by a nitrogen filling device. The conditions of the nitrogen working environment of the muffle furnace are: nitrogen pressure 6MPa, flow rate 13kg / h; Conditions: power 20KHz, nitrogen environment; after crushing, add polyphosphate, the amount of polyphosphate added is 3% of the total weight of shrimp and crab shells and distilled water, homogenize with a homogenizer for 15 minutes, let stand for 5 minutes, remove the precipitate, The rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com