Dual-concave high-voltage ceramic capacitor and manufacturing process thereof

A high-voltage ceramic and capacitor technology, applied in the field of high-voltage ceramic capacitors and manufacturing processes, can solve the problems of unadjustable electrode size, uneven electrode thickness, unadjustable capacitance, etc., to reduce the risk of tip discharge, high charge density, and reduced The effect of the risk of small tip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

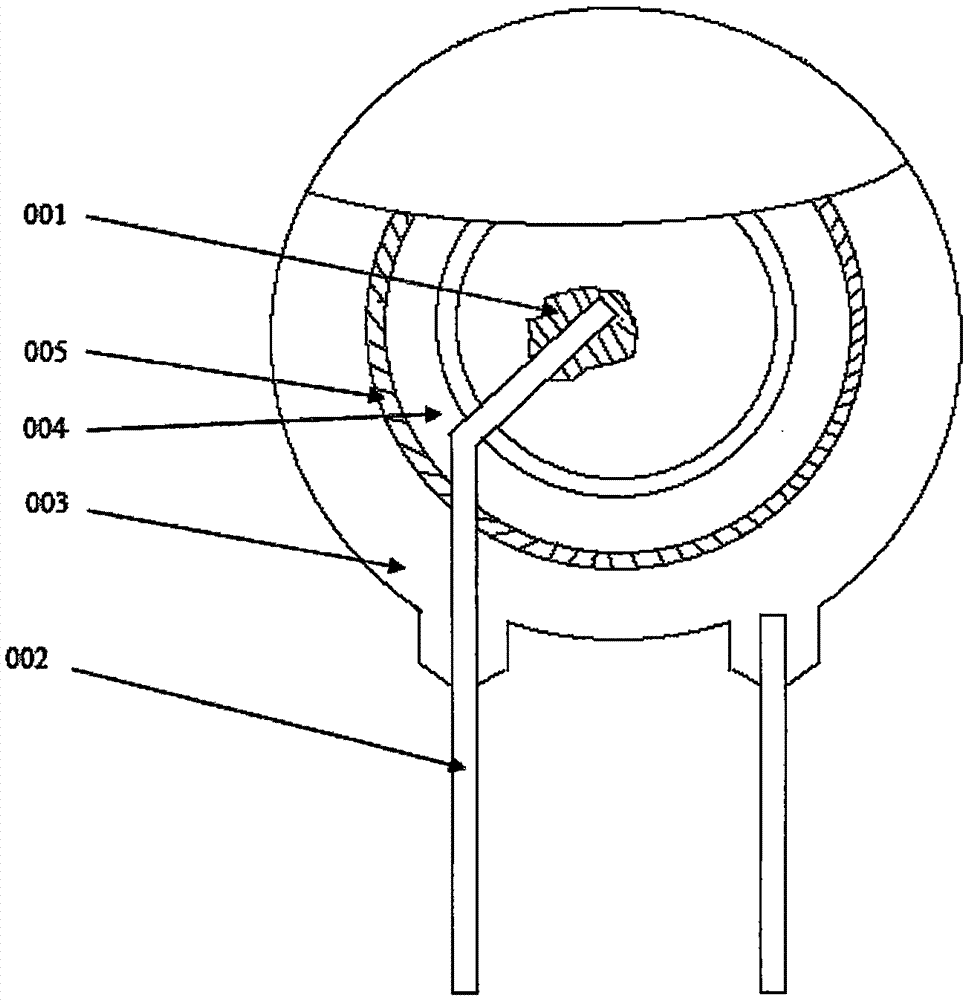

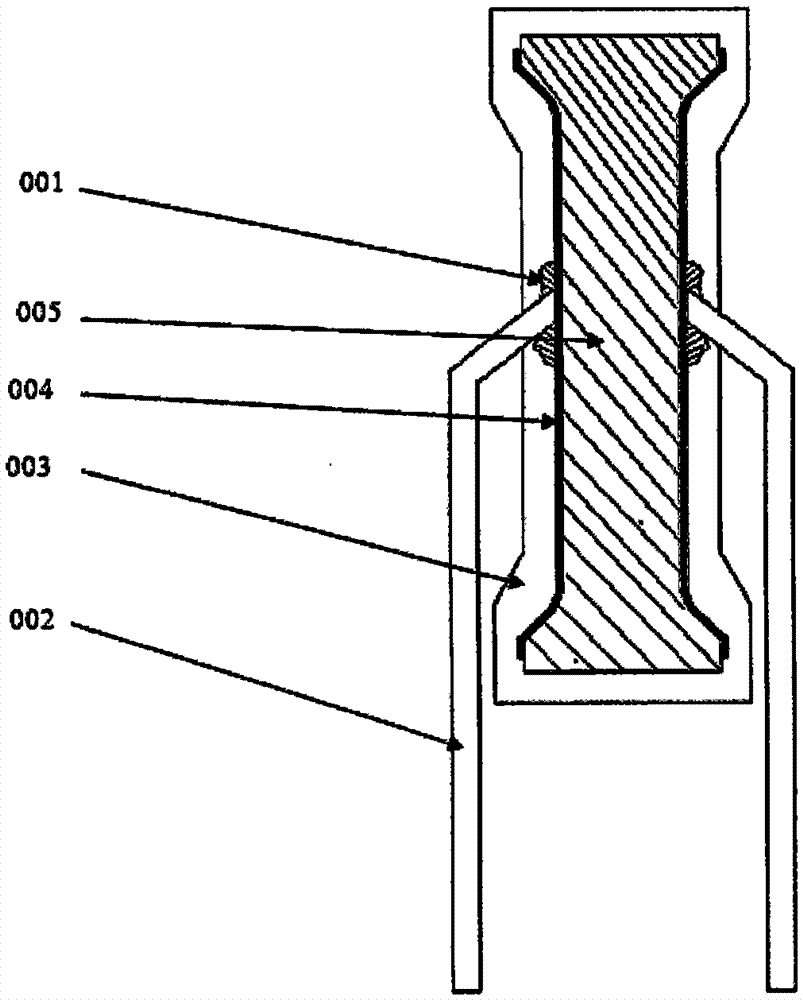

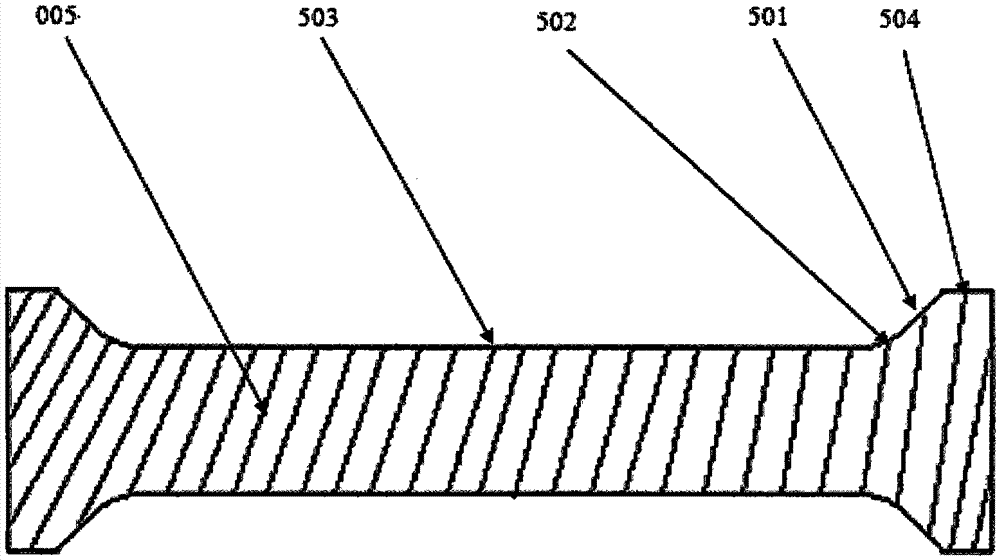

[0028] Embodiment 1, see attached figure 1 , 2, 3, and 4, a double-concave high-voltage ceramic capacitor related to the present invention includes solder 001, lead 002, resin encapsulation layer 003, electrode layer 004 and ceramic dielectric substrate 005, and the ceramic dielectric The substrate 005 is a centrally symmetrical cylinder with a frustum-shaped vacancy on the upper and lower bottom surfaces. The axis of the vacant frustum coincides with the axis of the ceramic dielectric substrate 005. The area of the circular surface of the circular frustum is smaller than the area of the bottom surface of the cylinder. The slope 501 on the side of the vacant circular frustum is smaller There is a transitional surface 502 with an arc section at the junction of the area circular surfaces, that is, the thickness of the central part of the ceramic dielectric substrate 005 is thinner than the edge, and there is a shape between the circular surface 503 at the center of the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com