Doped carbon dot and graphene compound as well as preparation method and application thereof

A doped graphene technology, applied in the field of nanomaterials, can solve the problems of high price of platinum catalysts, limited large-scale application, increased cost of fuel cell solutions, etc., and achieves a simple and easy preparation method, low cost, The effect of stabilizing chemical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

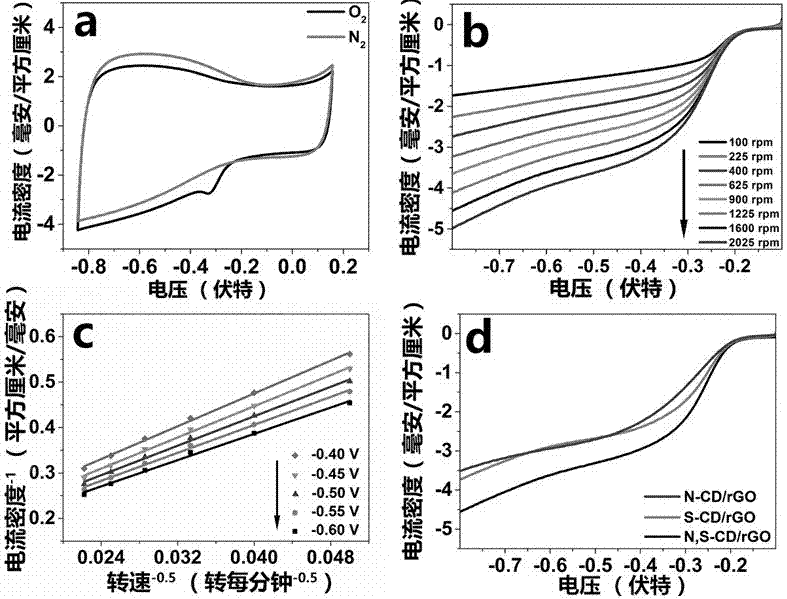

[0034] (1) Preparation of nitrogen and sulfur double-doped carbon dots using lipoic acid and ethylenediamine as raw materials

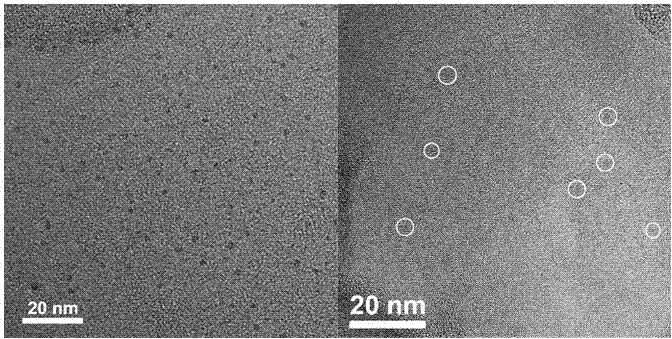

[0035] Dissolve 0.1 gram of lipoic acid, 0.06 gram of ethylenediamine and 0.02 gram of sodium hydroxide in 10 milliliters of deionized water, disperse evenly, transfer to a 50 milliliter polytetrafluoroethylene-lined reactor, and react at 250 ° C for 24 hours Afterwards, the reaction solution was taken out and filtered to remove impurities and dialyzed in deionized water for 48 hours with a 3500 Da molecular weight cut-off dialysis bag, and then the resulting solution was freeze-dried to obtain nitrogen and sulfur double-doped carbon dot powder solids.

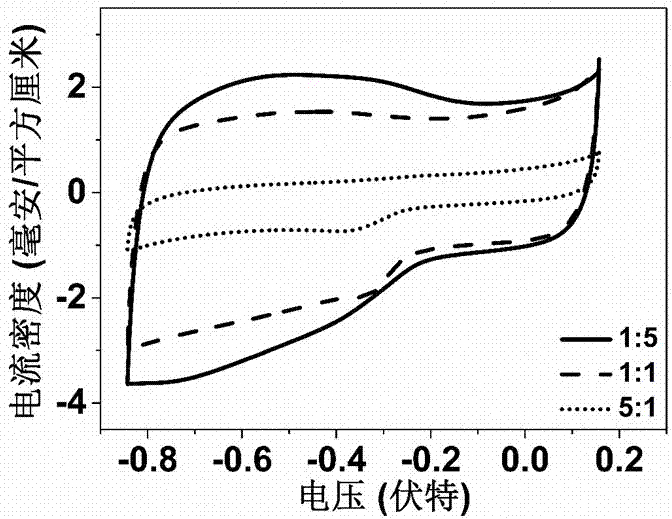

[0036] (2) Preparation of nitrogen and sulfur double-doped carbon dots and graphene composites

[0037] 20 mg of graphene oxide was dispersed in 10 mL of deionized water and ultrasonicated for 30 minutes to form a uniform dispersion, then 20 mg of nitrogen and sulfur double-doped carbon dots were adde...

Embodiment 2

[0039] (1) Preparation of phosphorus and sulfur double-doped carbon dots using lipoic acid and phytic acid as raw materials

[0040] Dissolve 0.1 g of lipoic acid and 0.06 g of phytic acid in 10 ml of deionized water, disperse evenly, transfer to a 50 ml polytetrafluoroethylene-lined reactor, react at 250 ° C for 24 hours, then take out the reaction solution and filter Impurities were removed and a dialysis bag with a molecular weight cut-off of 3500 Da was dialyzed in deionized water for 48 hours, and then the resulting solution was freeze-dried to obtain a solid phosphorus and sulfur double-doped carbon dot powder.

[0041] (2) Preparation of phosphorus and sulfur double-doped carbon dots and graphene composites

[0042] This step is the same as step (2) of Example 1, and the obtained product is the carbon dot / graphene composite material doped with phosphorus and sulfur in the present invention, named P,S-CD / rGO (1:1).

Embodiment 3

[0044] (1) Nitrogen and phosphorus double-doped carbon dots were prepared using phytic acid and ethylenediamine as raw materials

[0045] Dissolve 0.06 g of phytic acid and 0.02 g of ethylenediamine in 10 ml of deionized water, disperse evenly, transfer to a 50 ml polytetrafluoroethylene-lined reactor, react at 250 ° C for 24 hours, and then take out the reaction solution Impurities were removed by filtration and dialyzed in deionized water for 48 hours with a 3500 Da molecular weight cut-off bag, and then the resulting solution was freeze-dried to obtain a nitrogen-phosphorus double-doped carbon dot powder solid.

[0046] (2) Preparation of nitrogen and phosphorus double-doped carbon dots and graphene composites

[0047] This step is the same as step (2) of Example 1, and the obtained product is the phosphorous and sulfur double doped carbon dot / graphene composite material of the present invention, named N,P-CD / rGO (1:1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com