A trace ozone-aeration biofilter integrated reactor resisting impact load

A technology of biological aerated filter and ozone aeration, applied in the fields of granular microbial carrier treatment, chemical instruments and methods, oxidized water/sewage treatment, etc. To avoid problems such as low stability, to achieve the effect of ensuring efficient treatment, novel structure, and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

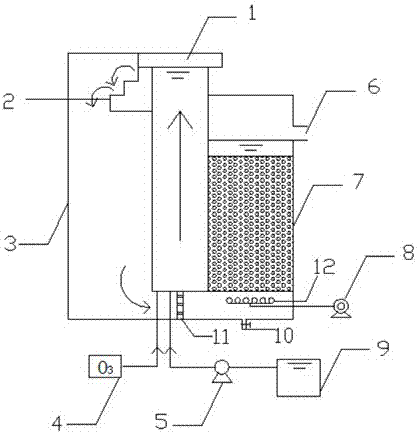

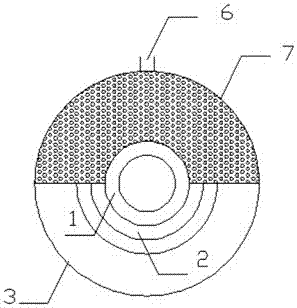

[0027] Embodiment 1: The micro-ozone biological aerated filter integrated reactor provided in this embodiment is suitable for advanced treatment of landfill leachate after biochemical treatment. like figure 1 and 2 As shown, the reactor adopts an inner and outer cylindrical sleeve structure, the inner cylindrical sleeve is used as a micro-ozone pre-oxidation unit, part of the outer cylindrical sleeve is used as a pre-oxidation water storage tank 3, and the other part is used as a biological aerated filter 7, wherein:

[0028] The bottom of the inner cylindrical sleeve is provided with an ozone aeration device, the upper part is provided with a gap in the water outlet area, and the upper part of the gap in the water outlet area is provided with an annular cover 1;

[0029] The upper part of the water storage tank 3 is provided with a water drop device 2, and the water drop device 2 is connected with the gap in the water outlet area;

[0030] A baffle is provided between the w...

specific Embodiment approach 2

[0049] Embodiment 2: This embodiment differs from Embodiment 1 in that the influent water of the reactor comes from the biochemically treated effluent in the leachate treatment process of a waste incineration plant. The ratio of reaction gas to water is 2:1, the hydraulic retention time is adjusted to 8h by the water flow speed, the ozone concentration is controlled by the ozone aeration device, and the aeration volume is controlled by the blower, both of which are continuously running. The measured influent average COD concentration is 400mg / L, ammonia nitrogen concentration is 90mg / L, and TN concentration is 120mg / L, and the average COD, ammonia nitrogen, and TN concentrations in the effluent water are 60mg / L, 5mg / L and 15mg / L respectively. The average removal rates of COD, ammonia nitrogen and TN in the reactor are 85%, 94% and 87.5% respectively.

specific Embodiment approach 3

[0050] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the influent of the reactor comes from the secondary effluent of leachate from a landfill site, and the water quality fluctuates greatly and the biodegradability is poor. The ratio of reaction gas to water is 2:1, and the hydraulic retention time is adjusted to 4 hours by the water flow rate. When the COD concentration of the influent changes from 300mg / L to 3000mg / L, the COD concentration of the effluent is between 50~350mg / L, and the average removal rate is 80 %, when the influent ammonia nitrogen is 90~120mg / L, the effluent ammonia nitrogen concentration is below 40mg / L, and the ammonia nitrogen removal rate reaches over 66.7%. When the influent TN concentration is 120~160mg / L, the effluent TN concentration is below 20mg / L, and the removal rate reaches 87.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com