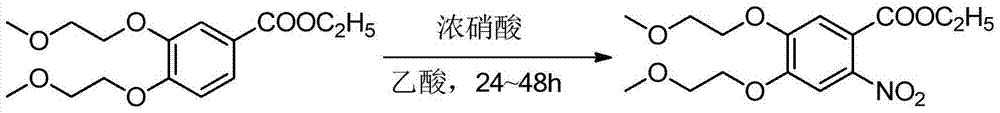

Erlotinib hydrochloride key intermediate preparation method

A technology of acetic acid and nitric acid, which is applied in the field of medicinal chemistry, can solve the problems of increased side reactions, reduced purity, and unsuitability for large-scale industrial production, and achieves the effects of reducing the generation of waste liquid, facilitating industrial production, and strong production operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

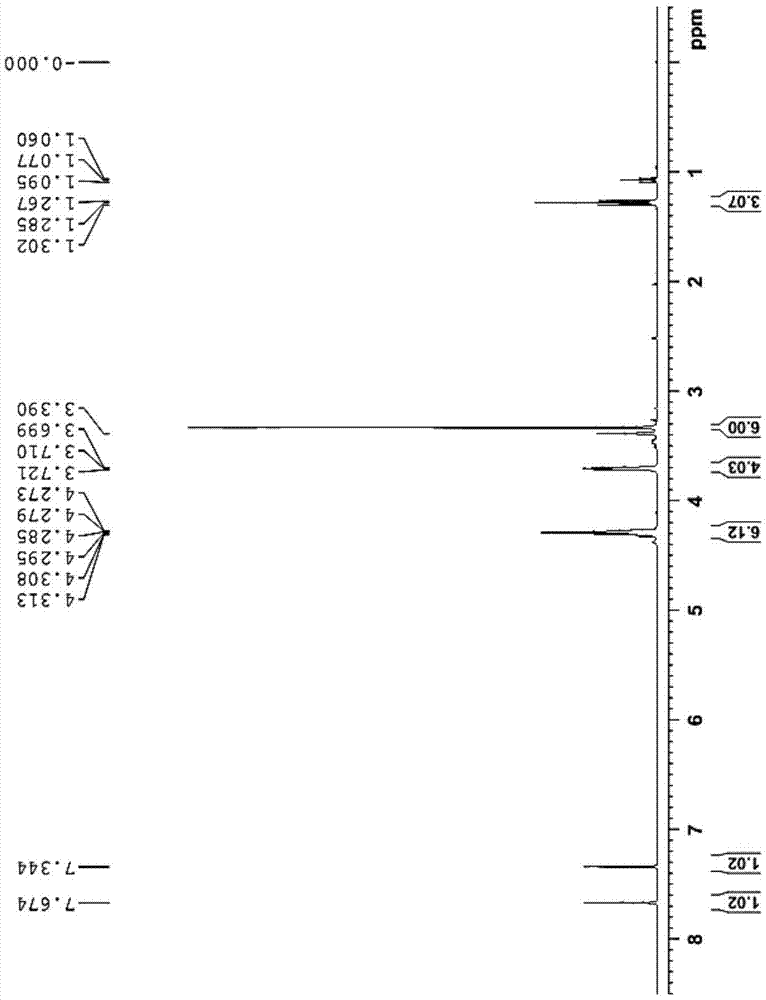

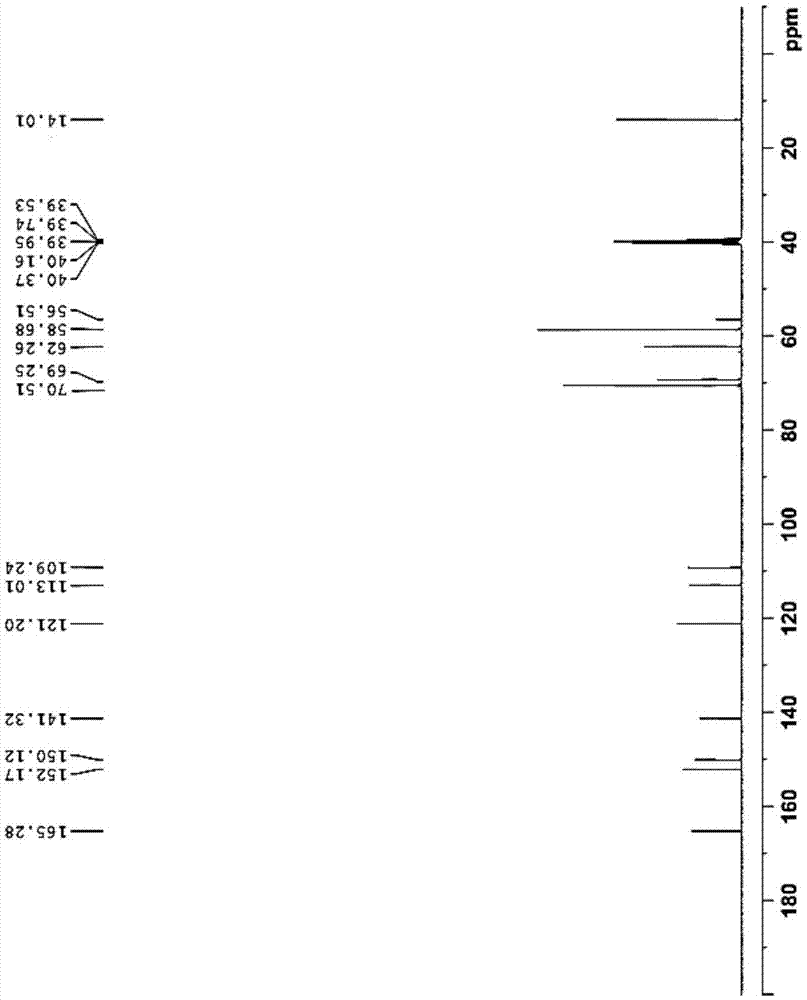

example 1

[0024] Glacial acetic acid (70L), acetic anhydride (10L) and 3,4-bis(2-methoxyethoxy) ethyl benzoate (23kg, 77.1mol) were added in the 200L reactor, and nitric acid ( 12L, 269.85 mol). Another concentrated sulfuric acid (200 ml, 3.85 mol) was diluted in glacial acetic acid (2 L). After the nitric acid was added dropwise, the diluted concentrated sulfuric acid glacial acetic acid solution was slowly added dropwise to the reaction kettle, the dropping was completed, and the temperature was raised to 40° C. to react for 2 hours. After the reaction is completed, the reaction solution is cooled to 20° C., slowly poured into the mixed solution of ice water (80L) and dichloromethane (80L) under stirring, the dichloromethane layer of the lower layer is separated, and the water layer of the upper layer is added with dichloromethane. (80L) extracted once, the lower organic layer was released, and the organic phases were combined. The organic phase was washed successively with purified...

example 2

[0027] Glacial acetic acid (80L), acetic anhydride (15L) and 3,4-bis(2-methoxyethoxy) ethyl benzoate (27kg, 90.5mol) were added in the 200L reactor, and nitric acid ( 14L, 316.75 mol). Another concentrated sulfuric acid (10 ml, 0.18 mol) was diluted in glacial acetic acid (1 L). After the nitric acid was added dropwise, the diluted concentrated sulfuric acid glacial acetic acid solution was slowly added dropwise to the reaction kettle, the dropping was completed, and the temperature was raised to 40° C. to react for 2 hours. After the reaction is completed, the reaction solution is cooled to 20° C., slowly poured into the mixed solution of ice water (80L) and dichloromethane (80L) under stirring, the dichloromethane layer of the lower layer is separated, and the water layer of the upper layer is added with dichloromethane. (80L) extracted once, the lower organic layer was released, and the organic phases were combined. The organic phase was washed successively with purified ...

example 3

[0029]Add glacial acetic acid (80L), acetic anhydride (15L) and ethyl 3,4-bis(2-methoxyethoxy)benzoate (25kg, 83.8mol) into a 200L reactor, and slowly add nitric acid ( 13 L, 293.3 mol). Another concentrated sulfuric acid (460ml, 8.4mol) was diluted in glacial acetic acid (1L). After the addition of nitric acid is completed, the diluted concentrated sulfuric acid solution in glacial acetic acid is slowly added dropwise to the reaction kettle. After the drop is complete, the temperature is raised to 40°C for 2 hours. After the reaction is complete, cool the reaction solution to 20°C, slowly pour it into a mixture of ice water (80L) and dichloromethane (80L) while stirring, separate the lower dichloromethane layer, and add dichloromethane to the upper water layer (80L) extracted once, the lower organic layer was released, and the organic phases were combined. The organic phase was washed successively with purified water (80 L), aqueous sodium bicarbonate (100 L), and saturated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com