Method for preparing SiTiOC ceramic coating

A ceramic coating and coating technology, applied in coating, metal material coating process, solid-state chemical plating, etc., can solve the problems of unfavorable ceramic composite coating preparation, difficult process control, complicated preparation steps, etc., and achieve friction The effect of lower coefficient, easy availability of raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

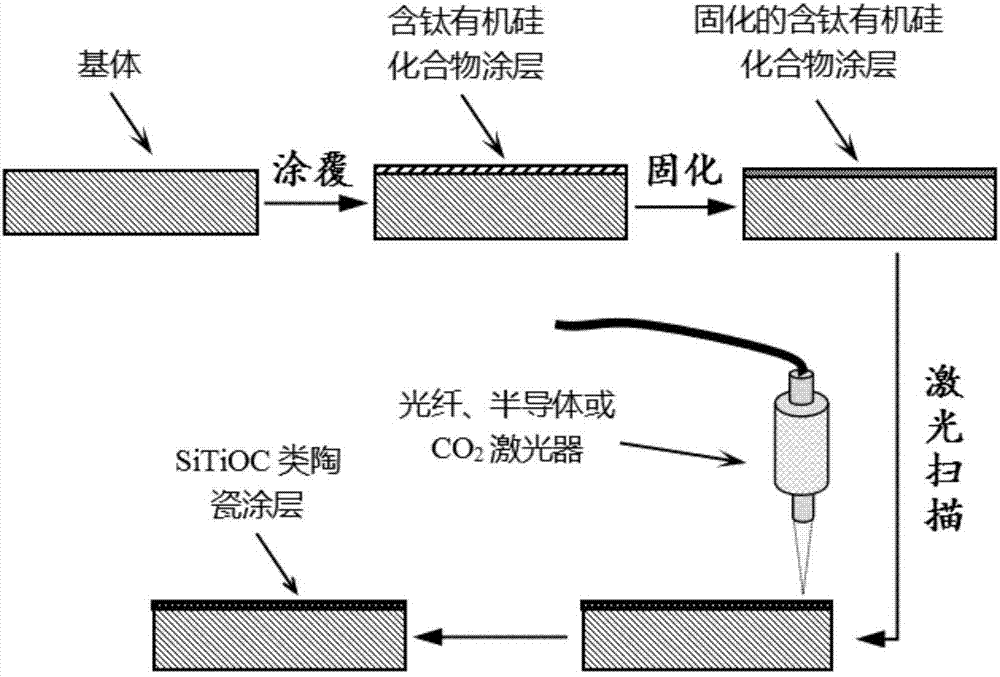

[0031] Embodiment 1 prepares the method (1) of SiTiOC ceramic coating

[0032] Step 1: Preparation of titanium organosilicon compound. According to the mass ratio of 1:1, weigh 100g each of γ-glycidoxypropyltrimethoxysilane and butyl titanate respectively, mix them in a 500mL beaker, and perform ultrasonic chemical reaction in a constant temperature water bath at 50°C for 5min , obtain a yellow transparent titanium organosilicon compound, its main molecular structure formula is:

[0033]

[0034] Step 2: Pretreatment of the metal surface to be coated. A 45 steel substrate with a size of 15 mm × 15 mm × 3 mm was sandblasted and ultrasonically cleaned in acetone solution for 15 min.

[0035] Step 3: Preparation of titanium organosilicon compound coating. Coating the titanium organosilicon compound prepared in step (1) on the surface of the 45 steel substrate to obtain a titanium organosilicon coating A with a thickness of 200 μm.

[0036] Step 4: Curing of the titanium si...

Embodiment 2

[0038] Embodiment 2 prepares the method (2) of SiTiOC ceramic coating

[0039] Step 1: Preparation of titanium organosilicon compound. According to the mass ratio of 3:2, weigh 60g of γ-glycidoxypropyltrimethoxysilane and 40g of butyl titanate respectively, mix them in a beaker, and perform ultrasonic chemical reaction in a constant temperature water bath at 40°C for 8min , obtain a yellow transparent titanium organosilicon compound, its main molecular structure formula is:

[0040]

[0041] Step 2: Metal surface pretreatment. A 45 steel substrate with a size of 15 mm × 15 mm × 3 mm was sandblasted and ultrasonically cleaned in acetone solution for 15 min.

[0042] Step 3: Preparation of titanium organosilicon compound coating. The titanium organosilicon compound prepared in step (1) was coated on the surface of the 45 substrate, and the thickness of the coated titanium organosilicon compound was 180 μm to obtain a titanium organosilicon coating A.

[0043]Step 4: Curin...

Embodiment 3

[0045] Embodiment 3 prepares the method (3) of SiTiOC ceramic coating

[0046] Step 1: Preparation of titanium organosilicon compound. According to the mass ratio of 4:1, weigh 80 g of γ-aminopropyltriethylsilane and 20 g of butyl titanate respectively, mix the two in a beaker, and perform ultrasonic chemical reaction in a constant temperature water bath at 30°C for 10 minutes to obtain Light yellow transparent titanium organosilicon compound, its main molecular structure formula is:

[0047]

[0048] Step 2: Metal surface pretreatment. A 45 steel substrate with a size of 15 mm × 15 mm × 3 mm was sandblasted and ultrasonically cleaned in acetone solution for 15 min.

[0049] Step 3: Preparation of titanium organosilicon compound coating. The titanium organosilicon compound prepared in step (1) was coated on the surface of the 45 substrate, and the thickness of the coated titanium organosilicon compound was 210 μm to obtain a titanium organosilicon coating A.

[0050] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com