Electroforming method of slotted waveguide

A technology of electroforming and waveguide, applied in the direction of electroforming, electrolysis, etc., to achieve the effect of simplifying the process, avoiding many burrs, and no processing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The slotted waveguide to be prepared is as Figure 10 As shown, the following preparation process is adopted:

[0025] Step 1: Prepare the core mold. The core mold consists of two parts, the lower structure 4 and the upper structure 7. The lower structure 4 of the core mold is a rectangular nickel layer structure with a thickness of L2. The adjacent rectangular nickel layer structures have the same length. The upper layer of the core mold Structure 7 is a micro-cuboid column array structure with a thickness of L4, and the specific preparation method is as follows:

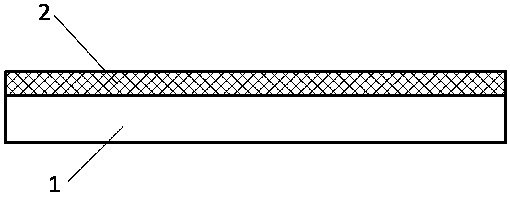

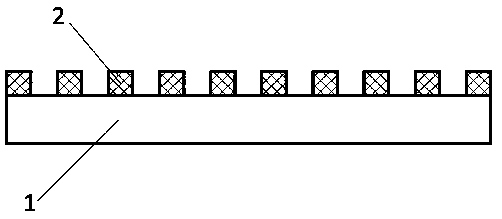

[0026] Step 1.1: coating a first layer of photoresist 2 with a thickness of L1 on the substrate 1;

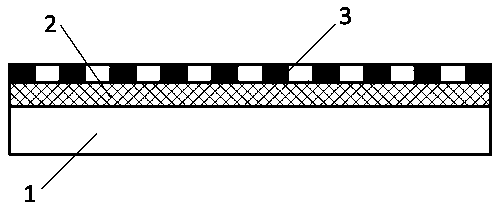

[0027] Step 1.2: Place the substrate 1 after the first coating in step 1.1 on the stage of the photolithography machine, and use the first mask plate 3 to perform the first exposure;

[0028] Step 1.3: Put the substrate 1 after the first exposure in step 1.2 into the developing solution for the first develo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com