Two-dimensional ultra-thin ZnO/BiOBr0.9I0.1 hybrid photocatalyst and preparation method thereof

A catalyst, ultra-thin technology, applied in the field of photocatalysis, to achieve good outdoor solar photocatalytic performance, simple preparation, simple production process and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Two-dimensional ultrathin ZnO / BiOBr with 20% ZnO mass percent 0.9 I 0.1 The preparation method of hybrid photocatalyst, the steps are as follows:

[0033] A two-dimensional ultra-thin Zn 5 (CO 3 ) 2 (OH) 6 Sheet preparation

[0034] (1) At room temperature, take by weighing 0.2469g of zinc acetate dihydrate, 0.0474g of CTAB, and 0.2704g of urea and dissolve them in 75ml of deionized water successively, and magnetic stirring makes it fully dissolve to obtain a zinc acetate concentration of 1.50×10 -2 Mixed solution of M.

[0035] (2) Transfer the above mixed solution into the inner lining of a 100ml autoclave, seal it, place it in a blast drying oven and heat it to a constant temperature of 80°C for 4 hours, then raise it to 120°C for 3 hours for hydrothermal reaction to obtain a two-dimensional Ultra-thin Zn 5 (CO 3 ) 2 (OH) 6 lamellae.

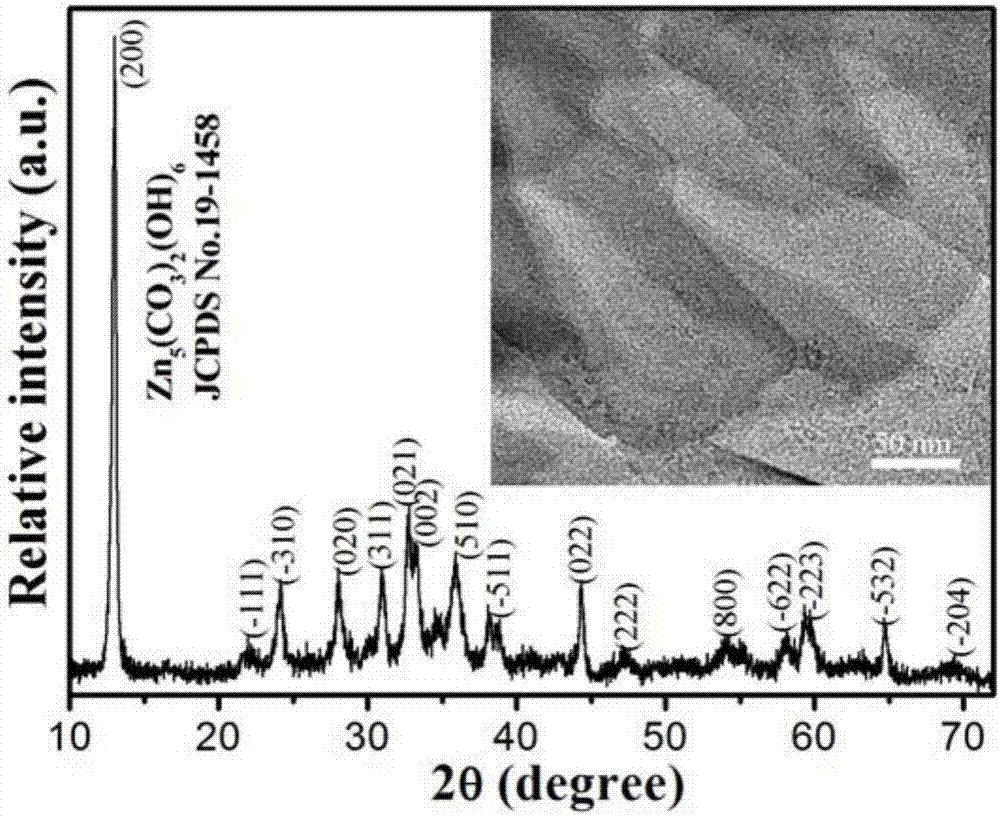

[0036] Precursor Zn 5 (CO 3 ) 2 (OH) 6 The X-ray diffraction (XRD) pattern of figure 1 As shown, it shows a bottom-c...

Embodiment 2

[0045] 2D Ultrathin ZnO / BiOBr with 10% ZnO Mass Percentage 0.9 I 0.1 The preparation method of hybrid photocatalyst, the steps are as follows:

[0046] A two-dimensional ultra-thin Zn 5 (CO 3 ) 2 (OH) 6 Sheet preparation

[0047] Operation process is with embodiment 1.

[0048] B two-dimensional ultra-thin 10w% ZnO / BiOBr 0.9 I 0.1 Preparation of hybrid photocatalyst

[0049] (1) At room temperature, the whole washed Zn 5 (CO 3 ) 2 (OH) 6 The ultra-thin layer was dispersed into 100ml of deionized water by ultrasound, and then 1.263g of NaBr and 0.183g of KI were added, dissolved under magnetic stirring and electrostatically adsorbed to them.

[0050] (2) Under magnetic stirring, 187.1 ml of bismuth nitrate ethylene glycol solution (7.0 g / L) was added dropwise to the system in step (1).

[0051] Immediately following the steps in Example 1, ZnO / BiOBr with a mass fraction of ZnO of 10% can be obtained 0.9 I 0.1 Hybrid composite (abbreviated 10ZB).

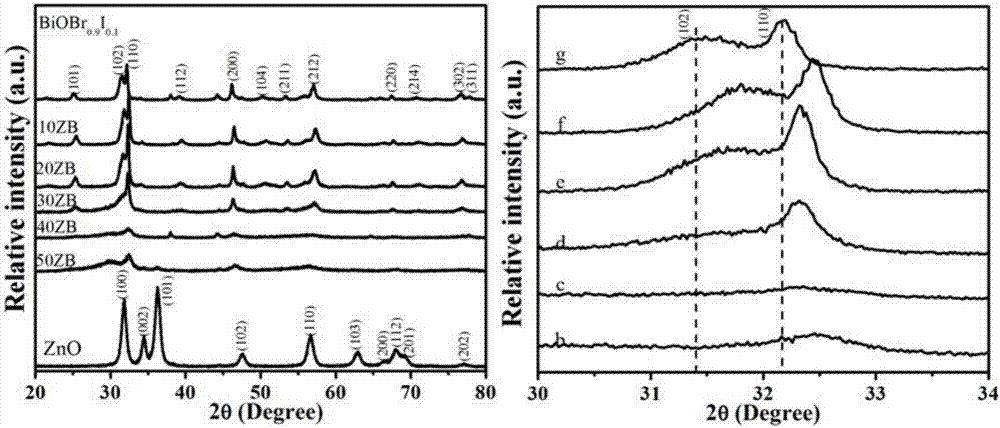

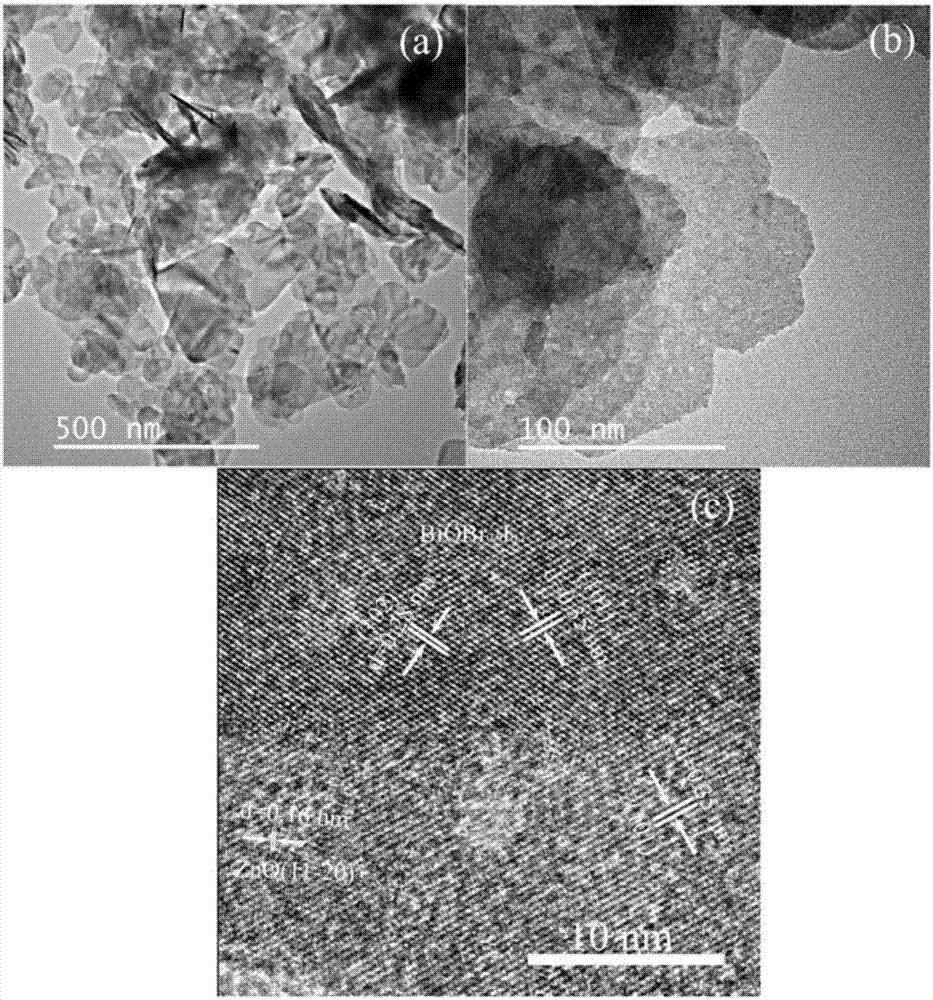

[0052] The XR...

Embodiment 3

[0054] Two-dimensional ultrathin ZnO / BiOBr with 40% ZnO mass percent 0.9 I 0.1 The preparation method of hybrid photocatalyst, the steps are as follows:

[0055] A two-dimensional ultra-thin Zn 5 (CO 3 ) 2 (OH) 6 Sheet preparation

[0056] Operation process is with embodiment 1.

[0057] B two-dimensional ultra-thin 40w% ZnO / BiOBr 0.9 I 0.1 Preparation of hybrid photocatalyst

[0058] (1) At room temperature, the entire washed precursor [Zn 5 (CO 3 ) 2 (OH) 6 ] The ultra-thin layer was dispersed into 100ml of deionized water by ultrasound, and then 0.210g of NaBr and 0.031g of KI were added, dissolved under magnetic stirring and electrostatically adsorbed with the precursor.

[0059] (2) Under magnetic stirring, 31.2 ml of bismuth nitrate ethylene glycol solution (7.0 g / L) was added dropwise to the system in step (1).

[0060] Immediately following the steps in Example 1, ZnO / BiOBr with a mass fraction of ZnO of 40% can be obtained 0.9 I 0.1 Hybrid composite (a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com