Method and device for comprehensively treating sewage through inorganic membrane, filler and fluid

A comprehensive treatment and fluid technology, applied in biological treatment devices, chemical instruments and methods, aerobic and anaerobic process treatment, etc., can solve the problems of limited biological implantation area, poor corrosion resistance, short service life, etc. The effect of prolonging the time of backwashing and chemical washing, strong corrosion resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

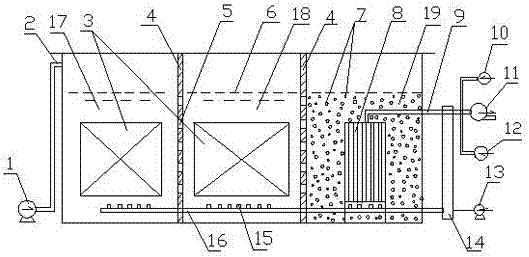

Examples

Embodiment Construction

[0010] The process for treating sewage with inorganic membranes, fillers and fluids is:

[0011] exist figure 1 Among them, the sewage treatment system includes a bioreactor, a water inlet device, a water production device 11, a chemical cleaning device 10, an aeration device 13, a backwash device 12 and an automatic control device 14, and the water inlet device includes an inlet pump 1 And the water inlet pipe 2 with one end connected to the bioreactor, the water production device includes a water pump, and the water outlet pipe 9 connected with the water pump at one end and connected with the flat ceramic membrane module at the other end, the chemical cleaning device includes a chemical cleaning pump, aeration The device includes an aeration pipe 16 extending into the anaerobic zone, aerobic zone and aerobic zone and the aeration holes 15 arranged at intervals in the aeration tube, the backwashing device includes a backwashing pump, and the automatic control device is connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com