Soluble fertilizer for corn drip irrigation

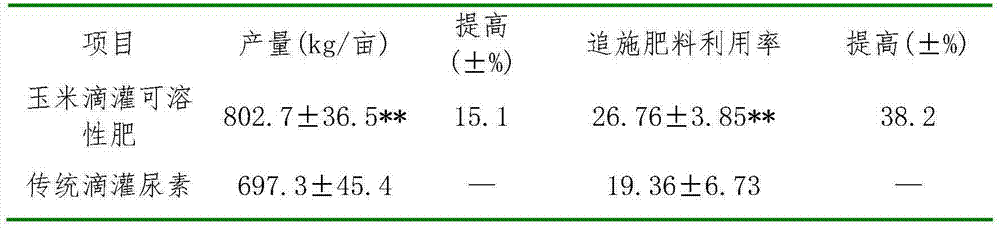

A soluble, corn-based technology, applied in the direction of alkaline orthophosphate fertilizer, nitrogen fertilizer, potash fertilizer, etc., can solve the problems of high price, increased production cost, waste of water and fertilizer resources, etc., achieves low corrosion, prolongs service life, and promotes the growth of corn Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Accurately weigh 40 kg of ammonium bicarbonate, 20 kg of potassium monohydrogen phosphate, 30 kg of potassium chloride, 0.5 kg of molybdenum jelly-like bacillus, 0.5 kg of bacillus lateral sporosum, 1 kg of bacillus licheniformis, 5 kg of sodium humate, and 0.5 kg of zinc sulfate , 0.25kg of chelated manganese, 0.25kg of chelated molybdenum, 1kg of proline, and 1kg of phenylalanine, which are finely pulverized by a high-power pulverizer, stirred and mixed, and quantitatively packed.

Embodiment 2

[0023] Accurately weigh 35 kg of ammonium bicarbonate, 20 kg of potassium monohydrogen phosphate, 35 kg of potassium chloride, 0.5 kg of Bacillus jelly-like, 1 kg of Bacillus lateralis, 4.5 kg of sodium humate, 1 kg of zinc sulfate, 0.25 kg of boric acid, and chelated manganese 0.25kg, 1kg of leucine, 1kg of proline, and 0.5kg of methionine, finely pulverized by a high-power pulverizer, stirred and mixed, and packaged quantitatively.

Embodiment 3

[0025] Accurately weigh 30 kg of ammonium bicarbonate, 25 kg of potassium monohydrogen phosphate, 35 kg of potassium chloride, 0.5 kg of Bacillus jelly-like, 1 kg of Bacillus lateral sporosum, 1 kg of Bacillus licheniformis, 4 kg of sodium humate, 0.5 kg of zinc sulfate, 0.5 kg of boric acid, Chelated manganese 0.25kg, chelated iron 0.25kg, leucine 0.5kg, proline 0.5kg, phenylalanine 1kg, finely pulverized by a high-power pulverizer, stirred and mixed, quantitative packaging.

[0026] Please give several examples of fertilizer preparation according to the pattern of Example 1, and at the same time, the dosage and materials used in each example are different so that the claims can be satisfied and supported by the description.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com