Soft backing material for clothing leather and preparation method thereof

A garment leather and soft bottom technology, applied in the field of garment leather, can solve the problems of poor hand feeling and poor environmental protection of garment leather, and achieve the effects of improving softness, meeting environmental protection requirements, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

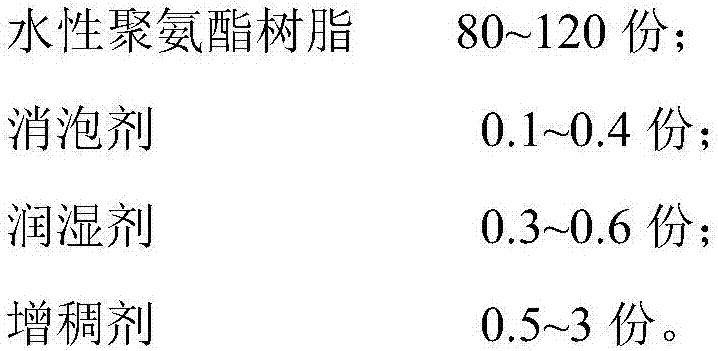

Method used

Image

Examples

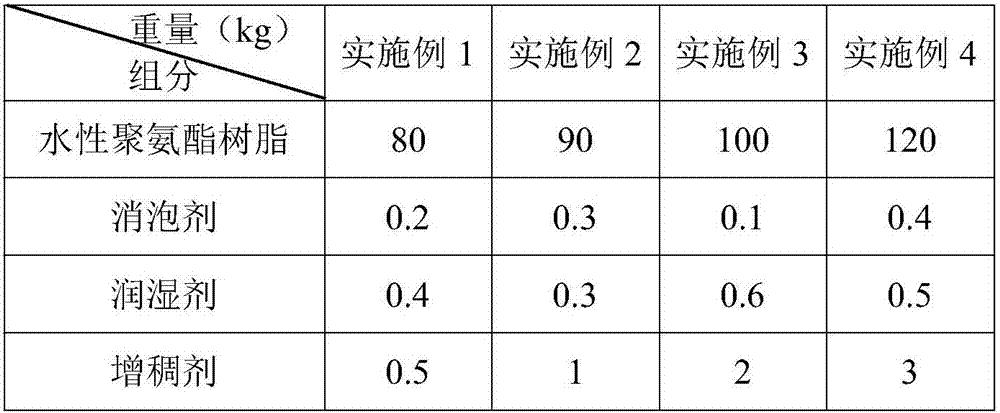

Embodiment 1

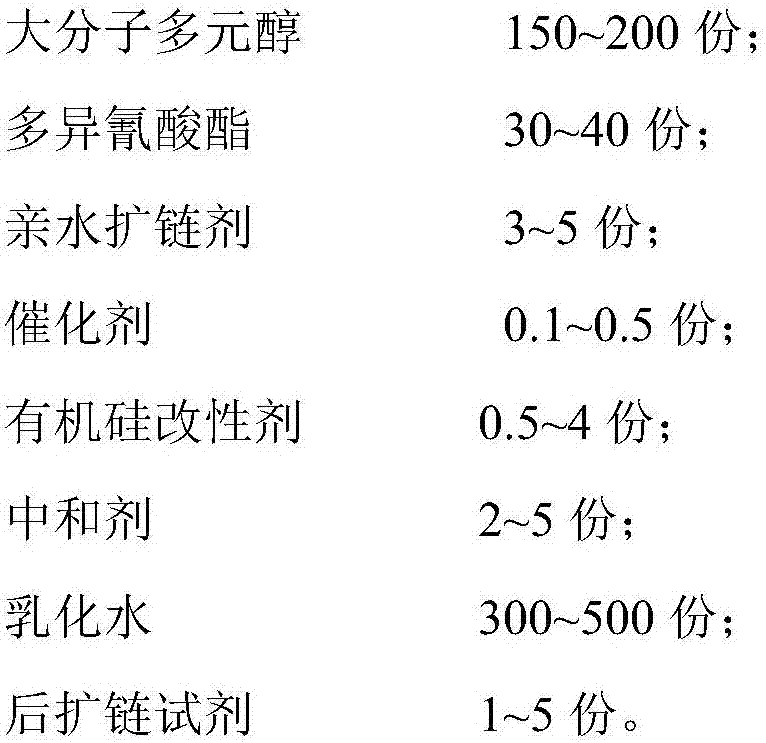

[0036] 1. Preparation of waterborne polyurethane resin

[0037] 1) Mix 150kg of polypropylene oxide diol and 35kg of TDI at 80°C for 1 hour;

[0038] 2) Adjust the temperature to 80°C, add 3kg of DMPA, 0.4kg of bismuth octoate and 5kg of diluent acetone, and mix for 2 hours;

[0039] 3) Adjust the temperature to 20°C, add aminosilane coupling agent KH5501kg, and mix for 1 hour;

[0040] 4) Adjust the temperature to 50°C, add 120kg of diluent acetone and mix; adjust the temperature to the required emulsification temperature of 10°C, add 2kg of triethylamine for neutralization, and add 300kg of emulsified water after 2 minutes of neutralization time under high-speed stirring, so that After being dispersed into an emulsion state, add 1kg of ethylenediamine to react, and the reaction time is 1h;

[0041] 5) Distill under reduced pressure at 30°C and vacuum -0.07MPa. After stirring for 2 hours, the test result shows that there is no acetone smell and odor, and the solid content o...

Embodiment 2

[0049]1. Preparation of waterborne polyurethane resin

[0050] 1) Mix 170kg of polyisoprene diol and 30kg of IPDI at 90°C for 1.5h;

[0051] 2) Adjust the temperature to 70°C, add 5kg of DMPA, 0.1kg of zinc octanoate and 8kg of diluent acetone, and mix for 3 hours;

[0052] 3) Adjust the temperature to 10°C, add 0.5kg of aminosilane coupling agent KH5500, and mix for 0.5h;

[0053] 4) Adjust the temperature to 55°C, add 140kg of diluent acetone and mix; adjust the temperature to the required emulsification temperature of 15°C, add 4kg of triethylamine for neutralization, and add 400kg of emulsified water under high-speed stirring after the neutralization time of 1min, so that After being dispersed into an emulsion state, 4kg of hexamethylenediamine was added for reaction, and the reaction time was 0.6h;

[0054] 5) Distill under reduced pressure at 50°C and vacuum at -0.08MPa. After stirring for 3 hours, the test result shows that there is no acetone smell and odor, and the ...

Embodiment 3

[0062] 1. Preparation of waterborne polyurethane resin

[0063] 1) Mix 190kg of polytetrahydrofuran ether and 40kg of NDI at 100°C for 2 hours;

[0064] 2) Adjust the temperature to 90°C, add 4kg of DMPA, 0.3kg of bismuth octoate and 10kg of diluent butanone, and mix for 1 hour;

[0065] 3) Adjust the temperature to 50°C, add 23 kg of aminosilane coupling agent Si-60, and mix for 2 hours;

[0066] 4) Adjust the temperature to 60°C, add 150kg of diluent butanone and mix; adjust the temperature to the required emulsification temperature of 25°C, add 5kg of triethylamine for neutralization, and add 500kg of emulsified water under high-speed stirring after the neutralization time is 5min. After being dispersed into an emulsion state, 5kg of o-xylylenediamine was added for reaction, and the reaction time was 0.2h;

[0067] 5) Distill under reduced pressure at 60°C and vacuum-0.09MPa, and after stirring for 4 hours, the test result shows that there is no butanone smell and odor, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com