Graphene composite conductive ink for ink-jet printing and preparation method thereof

A graphene composite, conductive ink technology, applied in inks, applications, household appliances, etc., can solve problems such as the inability to meet the requirements of printed electronic conductivity, the difficulty of graphene dispersion, and limited applications, and achieve excellent process performance and use. Performance, preparation process is simple and easy, no toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

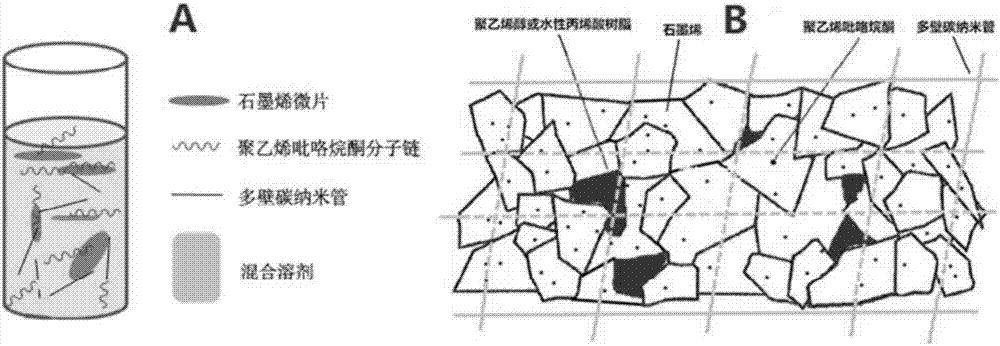

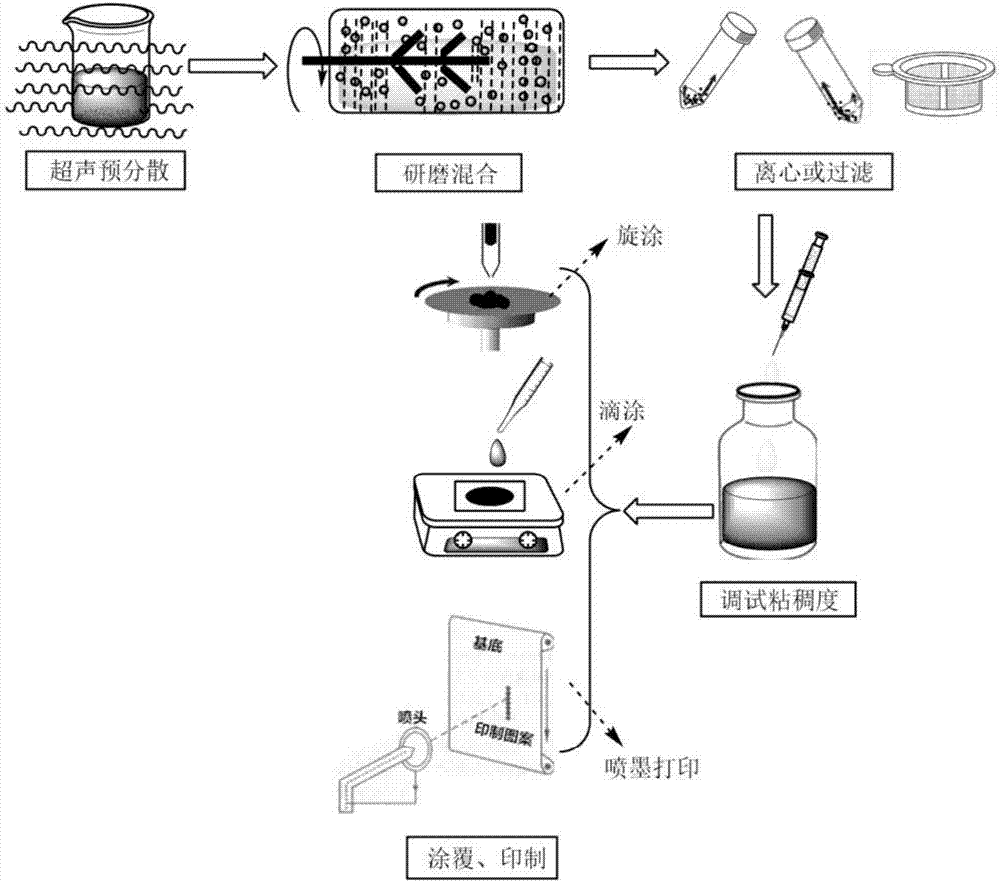

[0038] Such as figure 2 Shown, a kind of preparation method of graphene composite conductive ink comprises the steps:

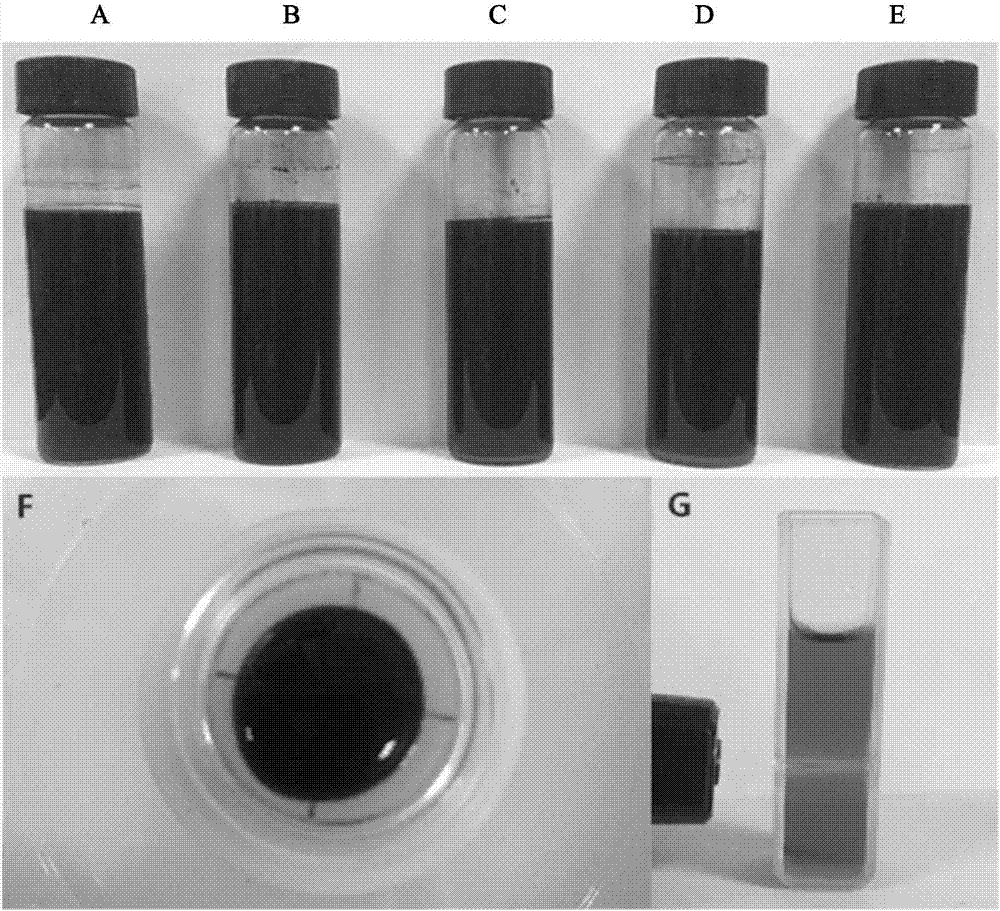

[0039] (1) Take each component by weight: 1 weight part of graphene, 0.25 weight part of multi-walled carbon nanotubes, 190 weight parts of ethanol, 120 weight parts of water, 0.25 weight part of polyvinylpyrrolidone and 0.3 weight part of polyvinyl alcohol ;

[0040] (2) Graphene, multi-walled carbon nanotubes and polyvinylpyrrolidone are added to ethanol and water simultaneously, and ultrasonic pre-dispersion is carried out to obtain a pre-dispersion;

[0041] (3) Putting the pre-dispersion liquid into a sand mill for grinding and mixing at one time, the rotating speed is 2000rpm, and the grinding and mixing time is 3h to obtain the graphene composite conductive paste;

[0042] (4) 3000rpm centrifugal 10min is carried out to the graphene composite conductive slurry of step (3) gained, to remove large-sized and the material that can't be dispersed well to...

Embodiment 2

[0045] Such as figure 2 Shown, a kind of preparation method of graphene composite conductive ink comprises the steps:

[0046] (1) Take each component by weight: 3 parts by weight of graphene, 0.3 parts by weight of multi-walled carbon nanotubes, 190 parts by weight of ethanol, 120 parts by weight of water, 0.5 parts by weight of polyvinylpyrrolidone and 0.9 parts by weight of polyvinyl alcohol ;

[0047] (2) Graphene, multi-walled carbon nanotubes and polyvinylpyrrolidone are added to ethanol and water simultaneously, and ultrasonic pre-dispersion is carried out to obtain a pre-dispersion;

[0048] (3) Putting the pre-dispersion liquid into a sand mill for grinding and mixing at one time, the rotating speed is 2000rpm, and the grinding and mixing time is 3h to obtain the graphene composite conductive paste;

[0049] (4) Carry out 1500rpm centrifugation 10min to the graphene composite conductive paste of step (3) gained, to remove large-sized and the material that can't be ...

Embodiment 3

[0052] Such as figure 2 Shown, a kind of preparation method of graphene composite conductive ink comprises the steps:

[0053] (1) Take each component by weight: 3 parts by weight of graphene, 0.75 parts by weight of multi-walled carbon nanotubes, 0.3 parts by weight of conductive carbon black, 220 parts by weight of ethanol, 70 parts by weight of water, 0.75 parts by weight of polyvinylpyrrolidone and 1 part by weight of polyvinyl alcohol;

[0054] (2) Graphene, multi-walled carbon nanotubes, conductive carbon black and polyvinylpyrrolidone are added to ethanol and water simultaneously, and ultrasonic pre-dispersion is carried out to obtain a pre-dispersion;

[0055] (3) Putting the pre-dispersion liquid into a sand mill for grinding and mixing at one time, the rotating speed is 2000rpm, and the grinding and mixing time is 6h to obtain the graphene composite conductive paste;

[0056] (4) 4000rpm centrifugal 10min is carried out to the graphene composite conductive paste o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com