Extreme pressure anti-wear lubricating grease composition and preparation method thereof

A grease composition, extreme pressure and anti-wear technology, applied in the field of grease, can solve the problems of unstable product performance, complex production process, poor lubrication stability, etc., and achieve good lubrication stability, good dispersion stability and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

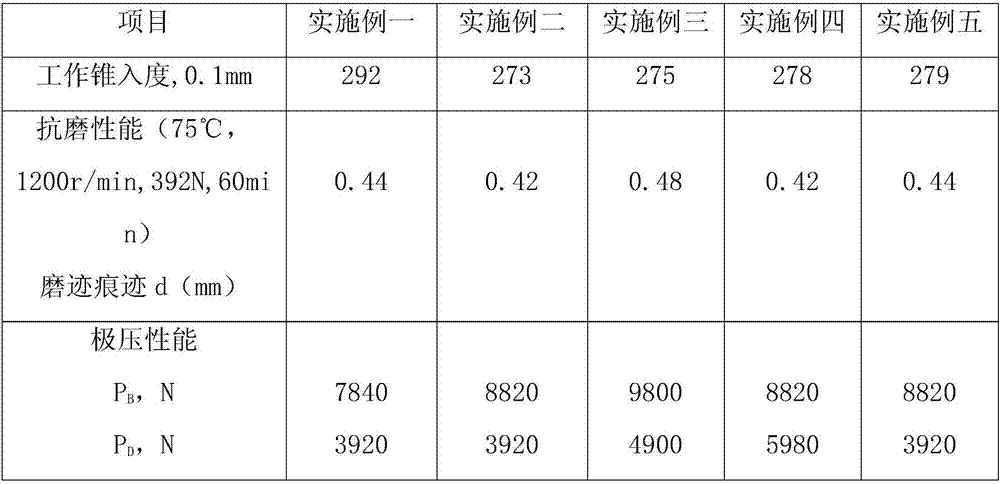

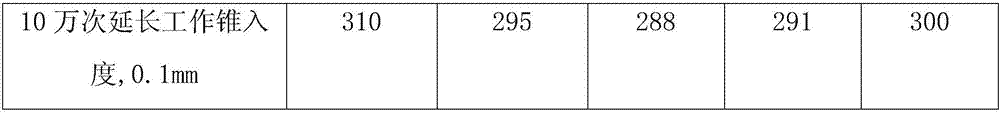

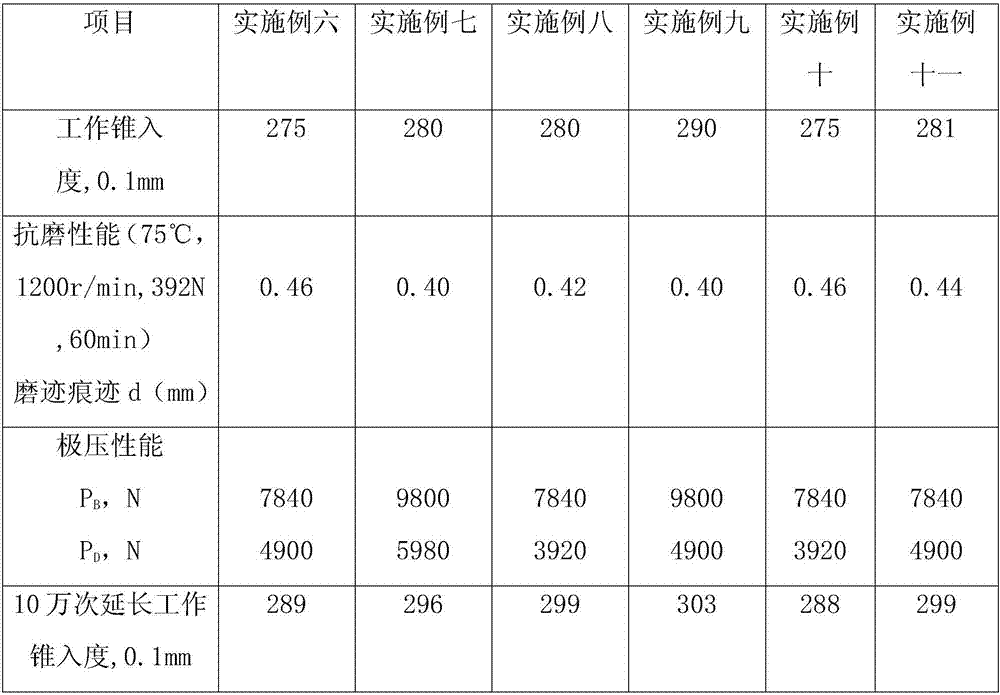

Examples

preparation example Construction

[0028] The preparation method of the extreme-pressure anti-wear grease composition provided in this example includes the following steps: After uniformly mixing the components according to the set weight percentage, heating to a temperature of 60-80°C, and then grinding to obtain the extremely Anti-wear grease composition; it is preferred to uniformly mix the components according to the set weight percentage, heat to a temperature of 70°C, and then grind; this preparation method is simple to operate, requires few procedures, and the prepared grease Excellent wear resistance, extreme pressure and stability, suitable for a wide range of applications; this temperature range is conducive to properly reducing the viscosity of the grease without affecting the performance of the final grease. Proper temperature rise and viscosity reduction are conducive to shortening Grinding time, grinding fully, mixing evenly, can finally prepare lubricating grease with excellent performance.

[00...

Embodiment 1

[0032] Take 65% of composite calcium sulfonate-based grease, 8% of copper powder (700 mesh), 10% of polyester, 15% of polyisobutylene (average molecular weight: 1300), 1.9% of antirust agent T706, and 0.1% of diphenylamine by weight percentage Add it into a small test kettle, mix evenly and heat to a temperature of 60°C, then put the heated mixture into a three-roll mill and grind until the solid additives are fully dispersed to obtain an extreme pressure anti-wear grease composition.

Embodiment 2

[0034] Take 75% of composite calcium sulfonate-based grease, 10% of copper powder (800 mesh), 5% of polyester, 8% of polyisobutylene (average molecular weight of 2400), 1% of antirust agent T706, and 1% of diphenylamine by weight percentage Add it into a small test kettle, mix evenly and heat it to a temperature of 80°C, then put the heated mixture into a three-roll mill to grind until the solid additives are fully dispersed, and then the extreme pressure anti-wear grease composition is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com