Preparation method of mono-atomic metal-carbon composite catalyst for electro-catalytic reactions

An electrocatalysis, carbon composite technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of increased specific surface area and poor conductivity of metal oxides. Good and unsuitable electrocatalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] An embodiment of the present invention provides a method for preparing a single-atom metal-carbon composite catalyst for electrocatalytic reactions, which includes the following steps:

[0026] S01. Mix the carbon material with the nitrogen source, under the protection of nitrogen, burn at 500°C-900°C for 1-5 hours, then raise the temperature to 1050°C-1150°C and burn for 1-5 hours, and finally cool down to room temperature to obtain the purpose carbon materials;

[0027] S02. Dissolving transition metal nitrate and / or acetate in the first volatile solvent to form a metal single atom source solution; uniformly dispersing the target carbon material in the second volatile solvent to form a dispersed Carbon material solution; while stirring, add the metal single atom source solution dropwise to the dispersed carbon material solution, and stir until the first volatile solvent and the second volatile solvent are completely volatilized Finally, stop stirring to obtain a meta...

Embodiment 1

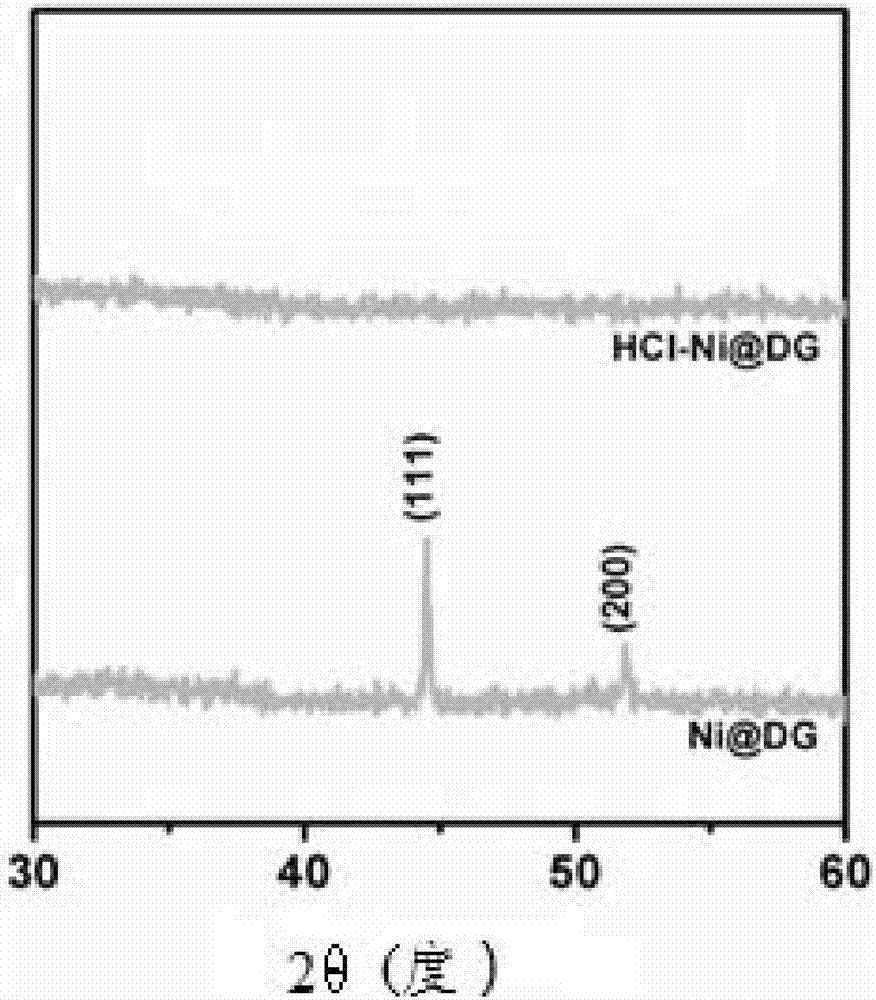

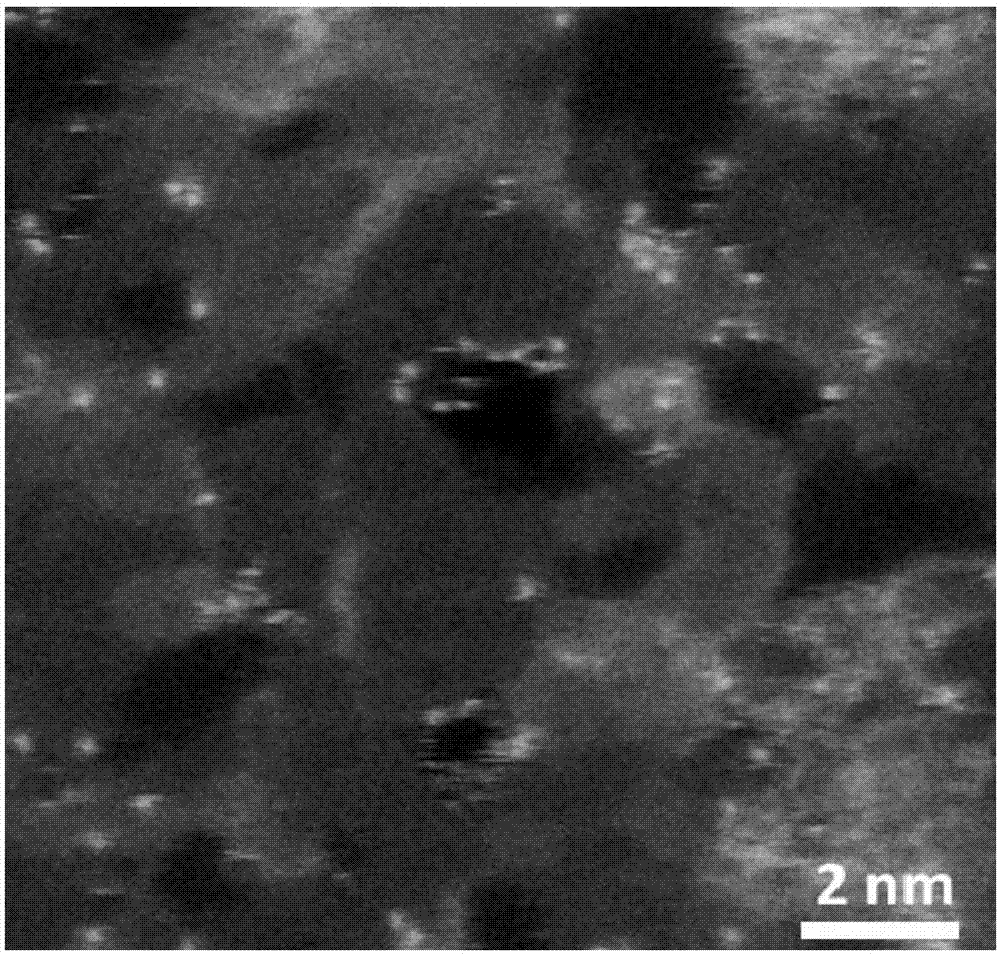

[0037] Mix 100mg of graphene and 100mg of melamine evenly, place in a tube furnace, heat to 750 degrees Celsius under a nitrogen atmosphere, burn for 2 hours, then heat up to 1050 degrees Celsius, burn for 2 hours, and finally drop to room temperature, A sample was removed and labeled DG. Ultrasonically disperse 3 mg of DG powder in 10 mL of ethanol solution, and add dropwise 0.034 mL of ethanol solution of nickel nitrate with a concentration of 0.1 M (ie mol / L, the same below). The mixed solution was stirred, and after 24 hours, the solvent evaporated completely to obtain a precipitate, which was transferred to a tube furnace, and burned for 2 hours at 750 degrees Celsius under nitrogen protection to obtain a graphene-supported nickel nanoparticle material (Ni @DG). Finally, the sample was placed in a hydrochloric acid solution with a concentration of 1M and stirred for 48 hours, washed several times with deionized water, and dried to obtain a graphene-supported single-atom ...

Embodiment 2

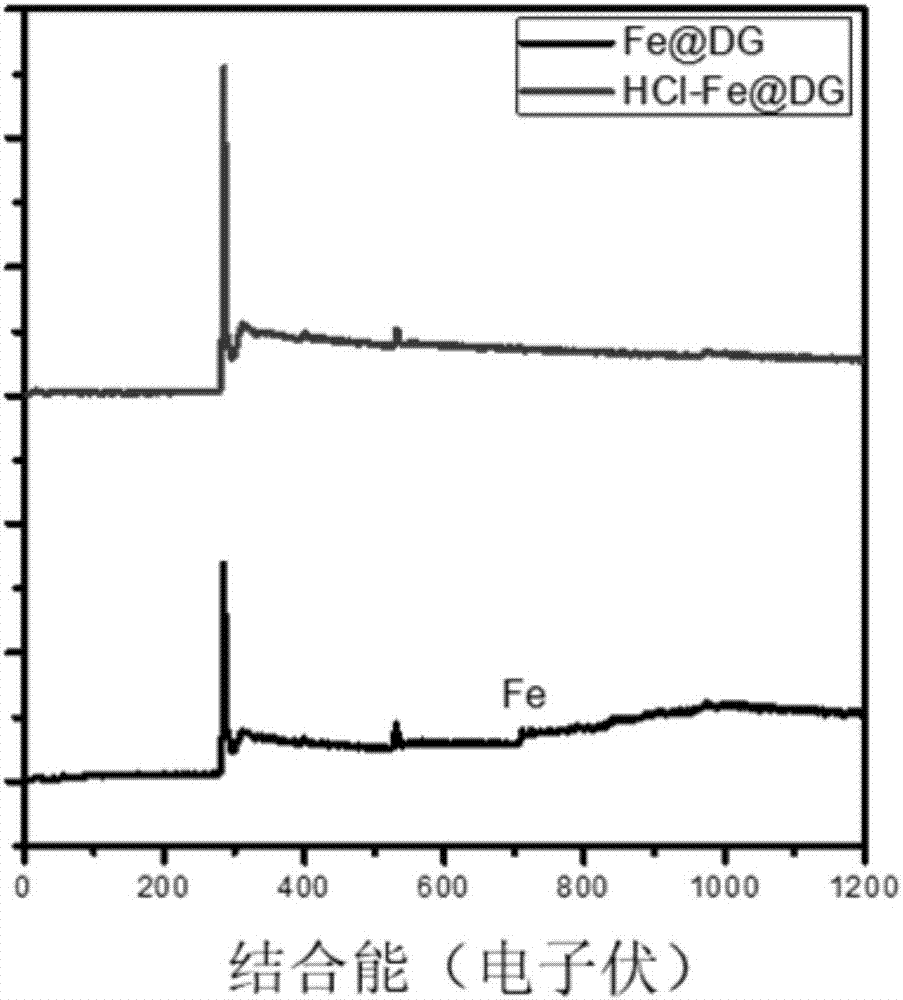

[0041] Mix 100mg of commercial graphene and 100mg of melamine evenly, place in a tube furnace, heat to 750 degrees Celsius under nitrogen atmosphere, burn for 2 hours, then raise the temperature to 1050 degrees Celsius, burn for 2 hours, and finally cool down to room temperature , a sample was taken and labeled DG. 3 mg of DG powder was ultrasonically dispersed in 10 mL of ethanol solution, and 0.034 mL of 0.1 M ferric nitrate solution in ethanol was added dropwise. The mixed solution was stirred, and the solvent evaporated completely after 24 hours to obtain a precipitate, which was transferred to a tube furnace and burned for 2 hours at 750 degrees Celsius under the condition of nitrogen protection to obtain iron nanoparticles supported graphene ( Fe@DG). Finally, the sample was placed in a hydrochloric acid solution with a concentration of 1M and stirred for 48 hours, washed several times with water, and dried to obtain a single-atom nickel-supported graphene material (HCl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com