Functional interface capable of self-driven directional transport of liquid, method and application thereof

A self-driven, interface technology, used in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the potential functions and applications of the interface that limit the directional collection of liquids, the single material of the liquid collection system, and the difficult directional transport. Collecting liquid and other problems, to achieve the effect of low preparation cost, safe droplet transmission process, and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

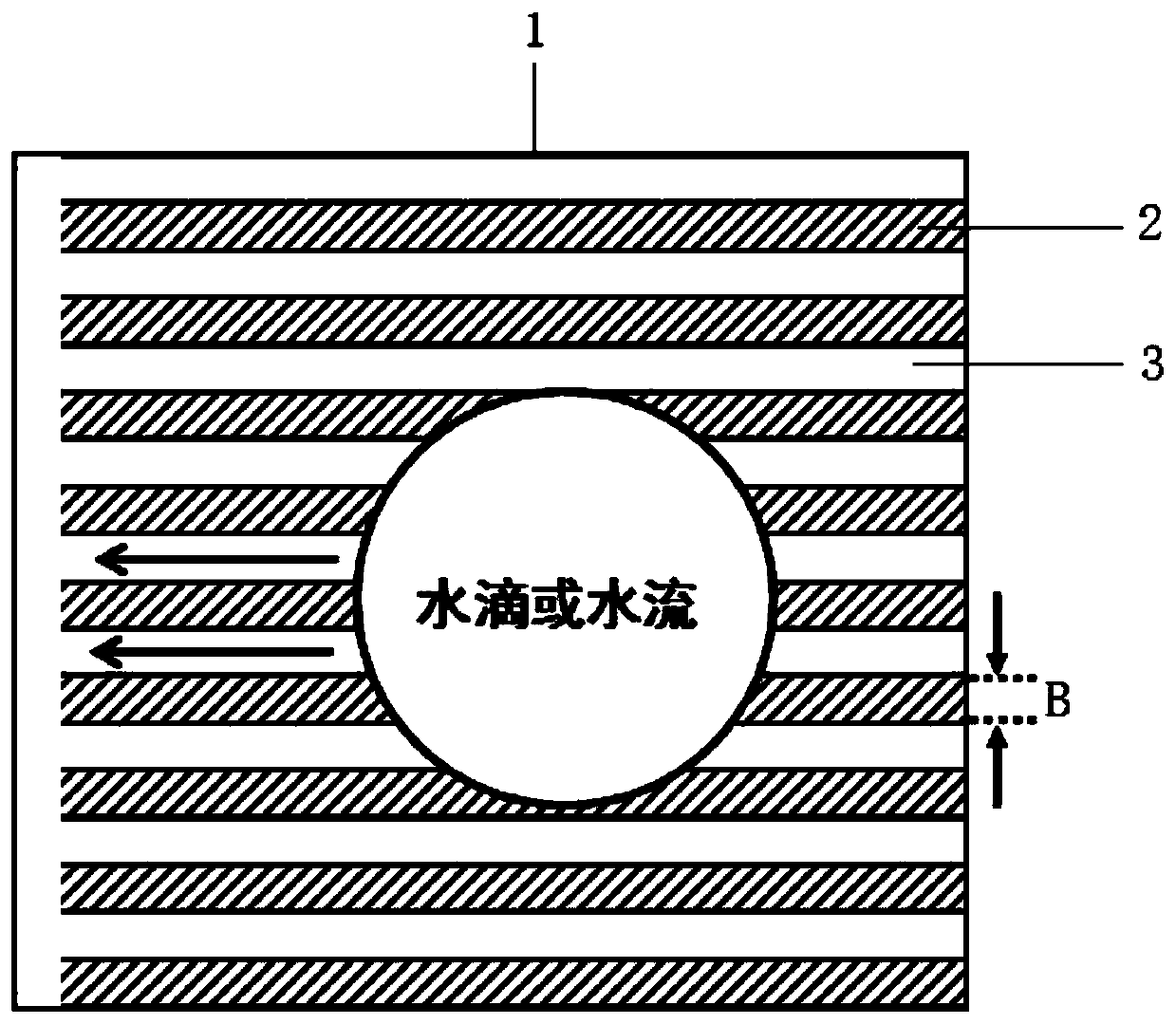

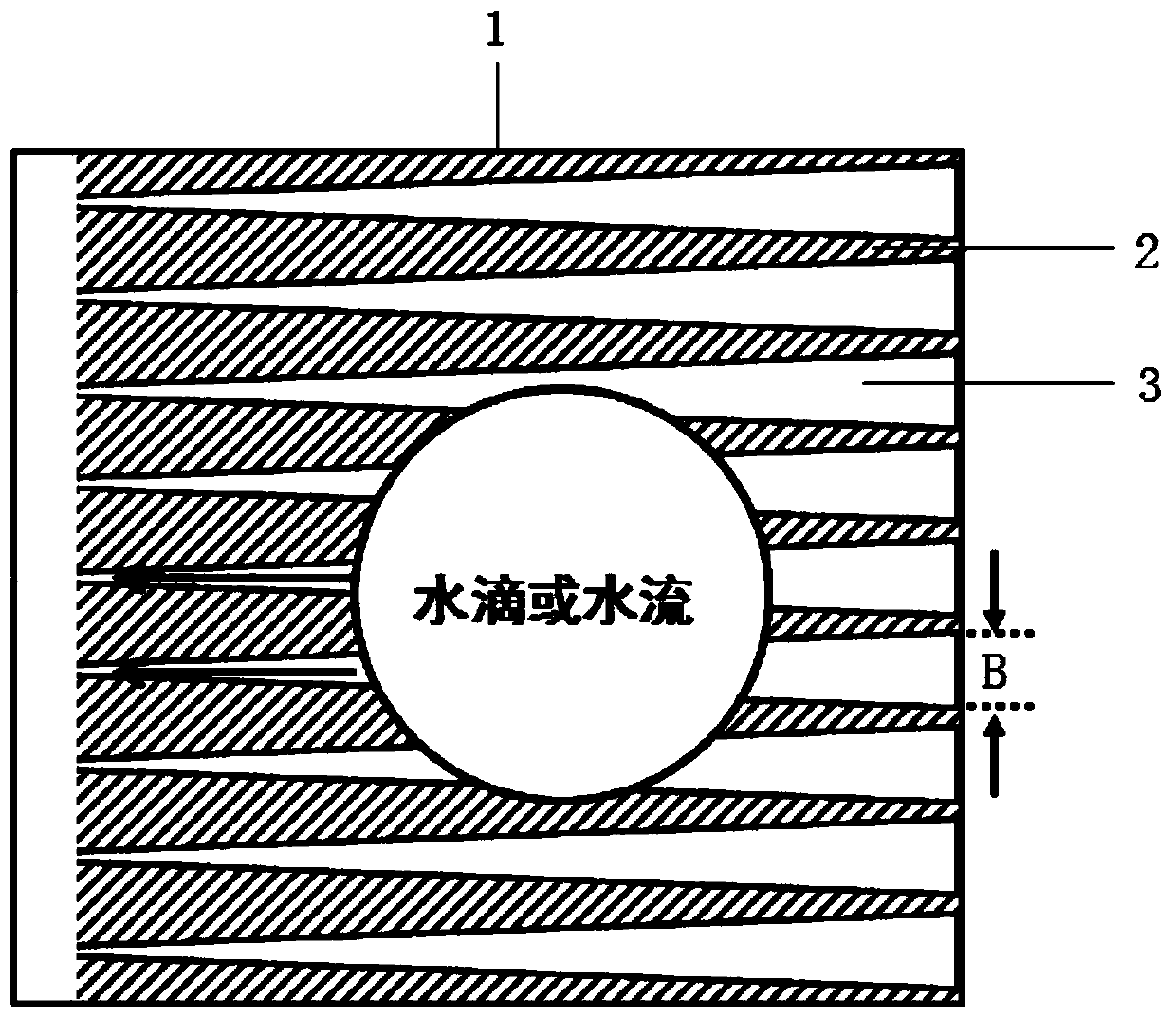

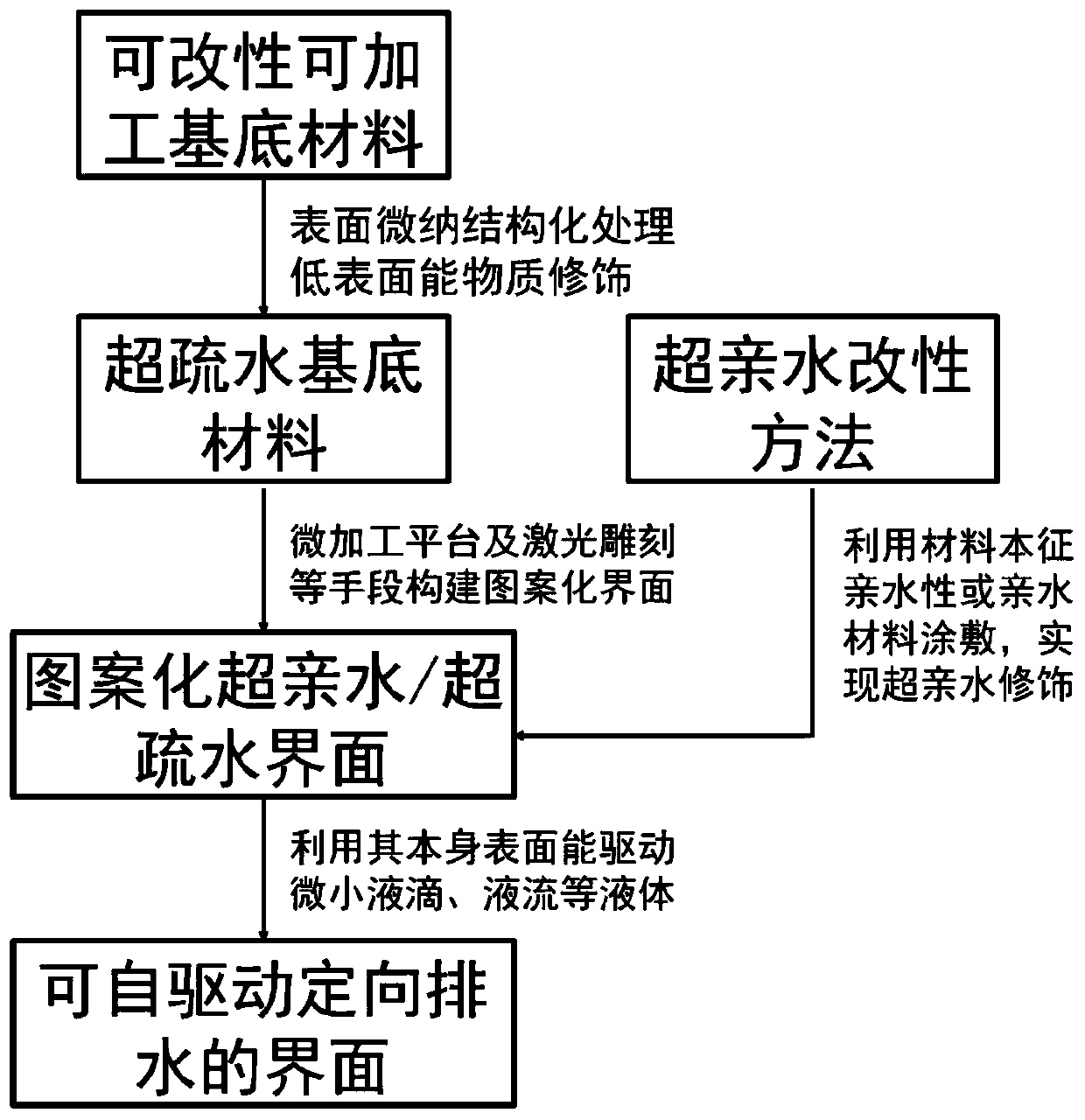

[0039] Use hydrophobic silica nanoparticles and polymethylsiloxane prepolymer to spin-coat on a commercial alumina ceramic plate (2mm thick), and heat it in an oven at 80 degrees for 1 hour to obtain superhydrophobic alumina ceramics piece. The ceramic sheet is patterned and polished using a micro-processing platform (numerical control engraving machine) to prepare super-hydrophobic regions 2 and super-hydrophilic regions 3 with strips of 200-1000 microns arranged alternately. Since the alumina ceramic sheet itself has strong hydrophilicity, no further treatment is required to obtain a superhydrophilic material. Use a humidifier to spray atomized droplets on the surface of the functional interface of the present invention, and it can be observed that the small droplets collected on the superhydrophobic surface will be quickly and directional transported by the surrounding superhydrophilic channels, realizing efficient collection and rapid transportation of mist transport.

Embodiment 2

[0041] The commercial red copper plate (1mm thick) was first surface polished and cleaned by ethanol ultrasonic cleaning. Soak the copper plate with 1M hydrochloric acid, take it out and wash it, soak the copper grid with 1M sodium hydroxide and 0.13M ammonium persulfate for 5-10 minutes, wash and dry. Further, after immersing in 1-5 mmol / L ethanol solution of dodecylmercaptan for 2-12 hours, rinse with ethanol to obtain a super-hydrophobic copper sheet after modification. A laser engraving machine is used to engrave and sinter strip-shaped or triangular superhydrophilic regions 3 with a thickness of 50 to 500 microns on the superhydrophobic copper sheet to obtain an interface with superhydrophobic regions 2 and superhydrophilic regions 3 . After the laser polishing of the hydrophobized copper substrate, the surface organic molecules are degraded, so that the intrinsic hydrophilicity of copper oxide can be reflected. Utilize the micro-sampler to apply 2-10 microliters of smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com