Micro electronmechanical system pressure sensor chip of beam film mechanism and preparation method thereof

A technology of pressure sensor and micro-electro-mechanical system, which is applied to the parts of TV system, fluid pressure measurement by changing ohmic resistance, generator/motor, etc., can solve the problems of reducing sensor deflection, poor linearity, and good temperature characteristics , to improve the sensitivity and temperature characteristics, the preparation process is simple and easy, and the effect of miniaturization is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with specific embodiments.

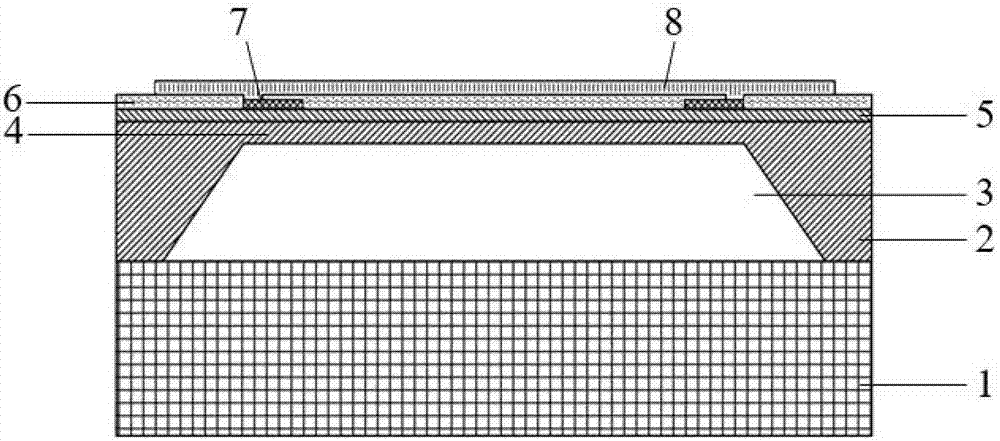

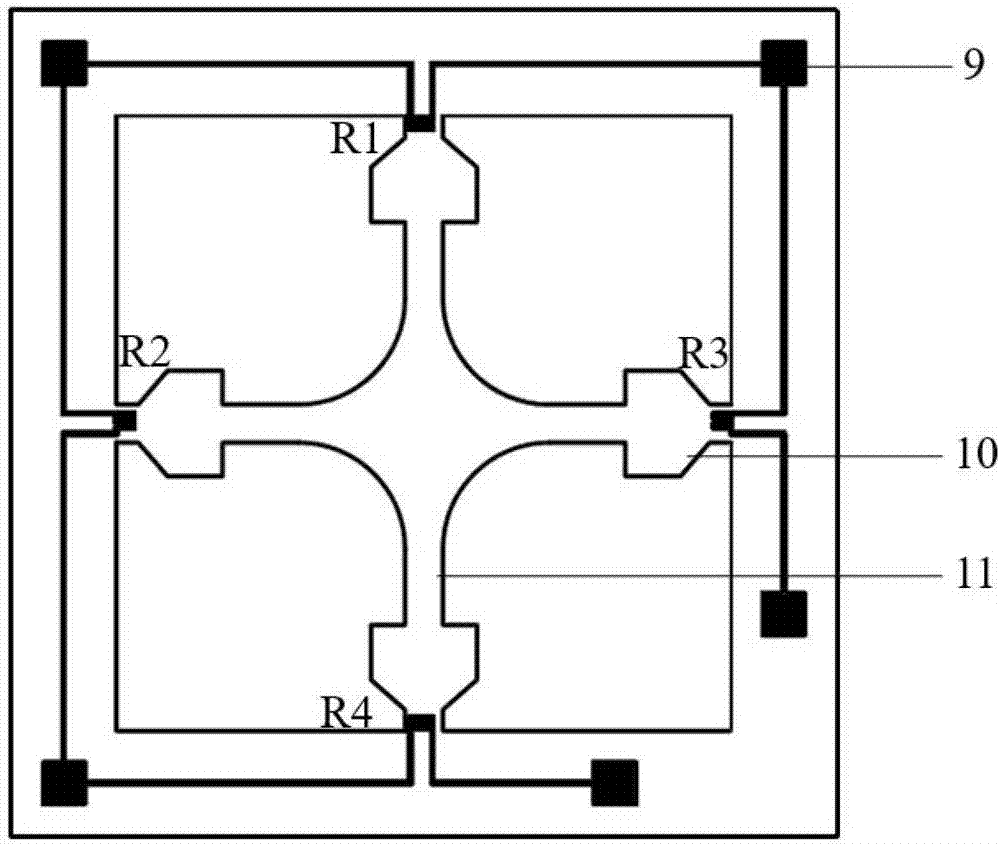

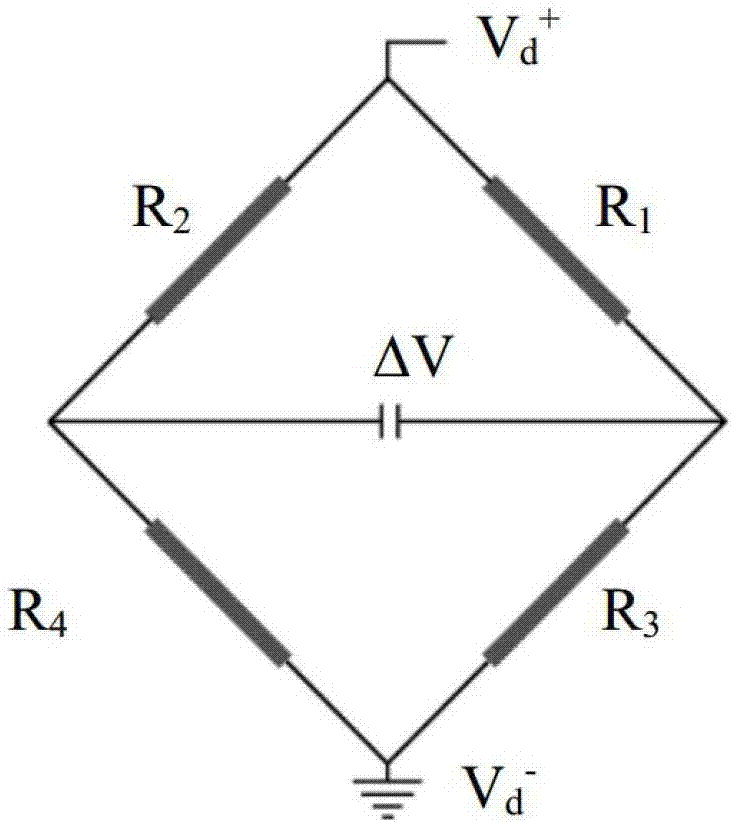

[0044] Such as Figures 1 to 3 shown. The invention discloses a MEMS pressure sensor chip of a beam-membrane mechanism, which includes the following components:

[0045] glass substrate 1;

[0046] n-type monocrystalline silicon element main body 2;

[0047] Isolation layer 5 (SiO 2 );

[0048] Protective layer 6 (Si 3 N 4 );

[0049] The outer edge of the n-type single crystal silicon element main body 2 is supported above the glass substrate 1, and the middle part of the n-type single crystal silicon element main body 2 is a hollow structure 3, so that an airtight cavity is formed between the two; the airtight cavity The top wall 4 is provided with a diaphragm pressure-sensitive structure;

[0050] The isolation layer 5 is arranged between the main body 2 of the n-type single crystal silicon element and the diaphragm pressure-sensitive structure;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com