Production method of milbemycin

A technology of milbemycin and production method, applied in the direction of organic chemistry and the like, can solve the problems of large amount of solvent recovery, large amount of solvent used, poor stability, etc., and achieve the effects of high purity, high equipment cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A production method of milbemycin, comprising the following steps:

[0062] The present invention also provides a kind of production method of Milbemycin, comprising the following steps:

[0063] Step a: filtering the milbemycin fermentation liquid to obtain the bacterial residue;

[0064] Step b: adding acetone or ethanol to the fungus residue in step a for stirring and extraction, the liquid-to-solid ratio of the acetone or ethanol to the fungus residue is 6-10L: 3kg, the stirring time is 5-7h, and then filtered to obtain Milbemycin extract;

[0065] Step c: Concentrating the milbemycin extract in step b until the volume content of acetone or ethanol is 20-30%, to obtain milbemycin extract;

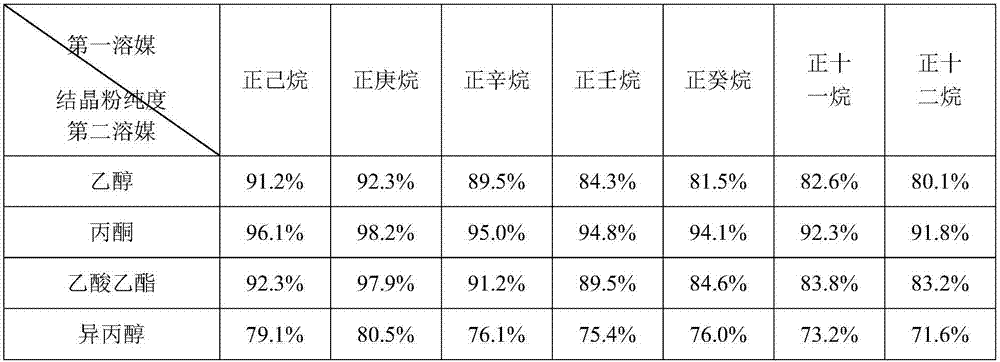

[0066] Step d: using the first solvent to dissolve the milbemycin extract obtained in step c to obtain the first milbemycin solution, wherein the ratio of the added amount of the first solvent to the bacterium residue in step b is 9 ~11L: 150kg;

[0067] Step e: Add the secon...

Embodiment 2

[0074] A kind of production method of milbemycin (production with 750kg bacterium residue as raw material, containing about 20kg of milbemycin), comprises the following steps:

[0075] Step a: filtering the milbemycin fermentation liquid to obtain the bacterial residue;

[0076] Step b: take 750kg of bacteria residue, put it into the extraction tank, add 2000L acetone, stir for 6h, and then filter to obtain the milbemycin extract;

[0077] Step c: Concentrating the milbemycin extract in step b until the volume content of acetone is 20-30%, to obtain milbemycin extract;

[0078] Step d: add 50L of acetone to the milbemycin extract obtained in step c to dissolve, and obtain the first milbemycin solution;

[0079] Step e: Slowly add 250L n-heptane to the first milbemycin solution in step d, control the flow rate of n-heptane addition to be 5.3-8.7L / min (completely added within 30-45min), and control the temperature at 20 ~30°C, stirred for 5 hours to crystallize, and filtered t...

Embodiment 3

[0084] A kind of production method of milbemycin (production with 750kg bacterium slag as raw material), operation steps are the same as embodiment 2, difference is that the acetone addition in step b is changed into 1500L, and stirring time is changed into 5h; The amount of acetone added in d and step f is changed to 45L; the amount of n-heptane added in step e and step g is changed to 240L, and the stirring and crystallization time is changed to 4.5h. Demilbemycin recrystallized powder 16.5kg.

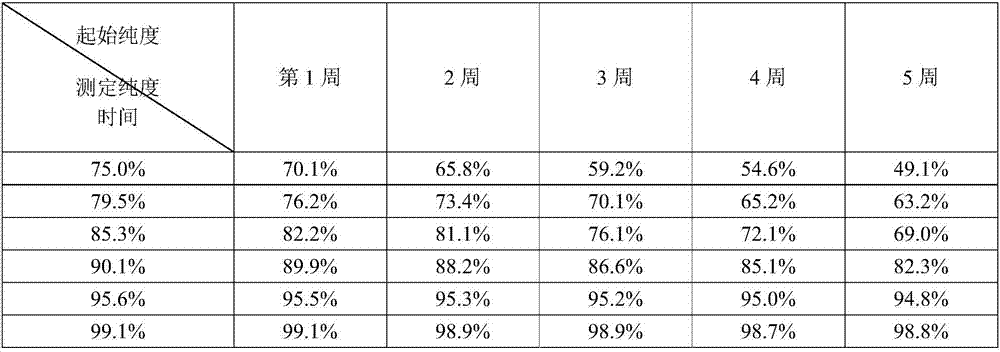

[0085] The purity of the obtained milbemycin recrystallized powder determined by HPLC was 97.3%, and the yield was about 82.5%. Yield calculation method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com