Liquid wormhole acid system and preparation method thereof

An acid-acid and wormhole technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of fast reaction speed of acid rock, serious secondary precipitation, short effective distance of acid solution, etc., and achieve long-term effective Effective distance, high chelating ability and good retarding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

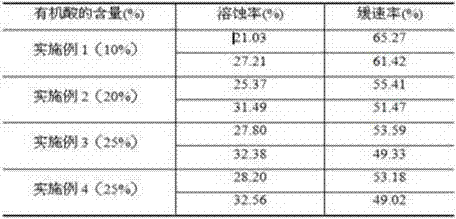

Embodiment 1

[0019] This embodiment provides a kind of wormhole acid liquid system, which is composed of the following substances in mass percentage: organic acid 10%, clay stabilizer 3%, polyglucoheptonate 15%, surfactant 3%, water 69%.

[0020] making process:

[0021] Under the experimental conditions of 50~60°C in a water bath, add the formula amount of organic acid and water into the round bottom flask, then add the clay stabilizer and polyglucoheptonate in turn under the action of stirring, and finally add the surfactant and keep stirring. Stir until the solution is transparent, clear, and free from precipitation, stop stirring, and let it stand for 1 hour.

[0022] In this embodiment, the organic acid is formic acid; the clay stabilizer is type II polyaminomethacrylamide, the degree of polymerization is greater than 3000, and the manufacturer is Chengdu Anshide Petroleum Technology Development Co., Ltd.; polyglucoheptonate is Sodium polyglucoheptacarbonate, the relative molecular ...

Embodiment 2

[0024] This embodiment provides a wormhole acid liquid system, which is composed of the following substances in mass percentage: 20% organic acid, 3% clay stabilizer, 15% polyglucoheptonate, 3% surfactant, water 59%.

[0025] The preparation method is the same as in Example 1.

[0026] In this example, the organic acid is acetic acid; the clay stabilizer is type II polyaminomethacrylamide, the degree of polymerization is greater than 3000, and the manufacturer is Chengdu Anshide Petroleum Technology Development Co., Ltd.; polyglucoheptonate is Potassium polyglucoheptate carbonate, the relative molecular weight is greater than 100,000; the surfactant is a nonionic amphoteric surfactant, hydroxyl synthetic alcohol polyoxyethylene ether, and the degree of polymerization is greater than 3,000.

Embodiment 3

[0028] The present embodiment provides a wormhole acid liquid system, which is composed of the following substances in mass percentage: 25% organic acid, 3% clay stabilizer, 15% polyglucoheptonate, 3% surfactant, water 49%.

[0029] The preparation method is the same as in Example 1.

[0030] In this embodiment, the organic acid is ammonium triacetate, the clay stabilizer is type II polyaminomethacrylamide, the degree of polymerization is greater than 3000, and the manufacturer is Chengdu Anshide Petroleum Technology Development Co., Ltd.; polyglucoheptonic acid The salt is sodium polyglucoheptacarbonate, the relative molecular weight is greater than 100,000; the surfactant is anionic surfactant ammonium lauryl sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com