A composite sand-fixing model and its preparation method and application

A technology of model and reinforcement solution, applied in application, chemical instruments and methods, fertilizer mixture, etc., can solve the problems of low crust strength, easy cracking by wind erosion, poor tolerance and other problems of microbial solidified sandy soil crust, and is suitable for large-scale use , Facilitate growth and improve surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

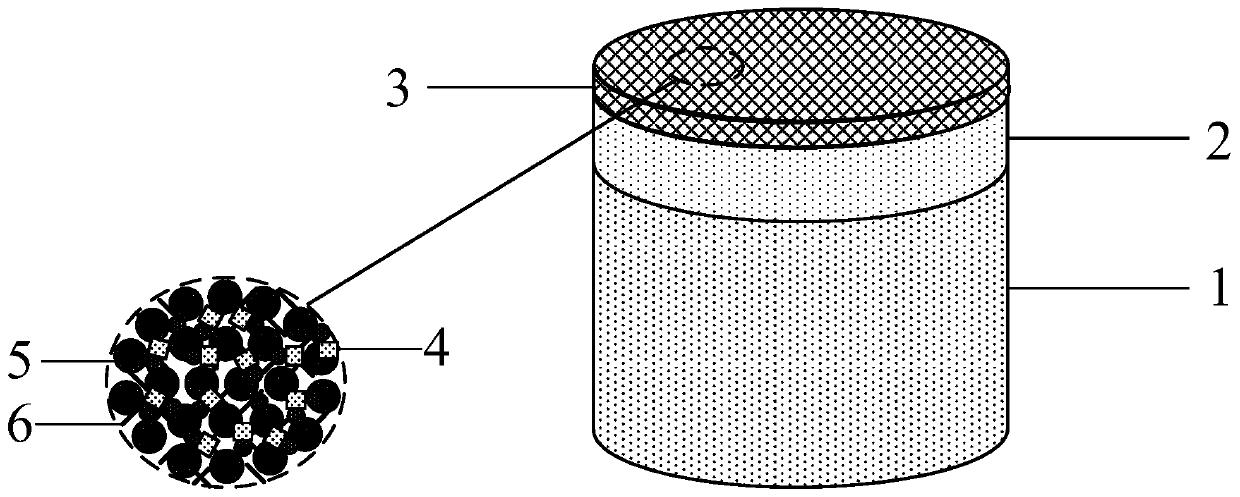

[0024] A method for preparing a composite sand-fixing model, comprising the following steps:

[0025] (1) Preparation of microbial reinforcement solution: press Bacillus pasteurianus by 10 7 ~10 9 each / mL is inoculated into the culture solution to obtain the bacterial solution, and the bacterial solution is mixed with the treatment solution in an equimolar ratio to obtain a microbial reinforcement solution; the treatment solution is a mixture of urea and an aqueous solution of calcium chloride in an equimolar ratio.

[0026] The medium components of Bacillus pasteurianus are: 20g / L yeast extract, 10g / L NH 4 Cl, 2.4g / L NiCl 2 , 1g / L MnSO 4 , using 0.1g / L NaOH solution to adjust the pH of the culture medium to 9; mix it evenly with a magnetic stirrer and place it in a high-temperature autoclave at 120°C for 30 minutes; And placed in a constant temperature shaking incubator, 30 ℃, 100r / min culture 24h standby.

[0027] Measuring the activity of the bacterial liquid: measurin...

Embodiment 2

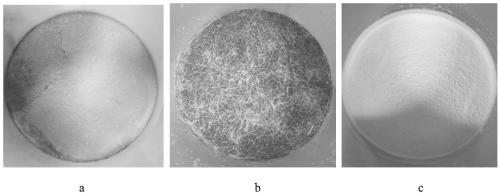

[0038] The superiority of the composite sand-fixing model was verified by preparing two different types of sand-fixing models.

[0039] 1. Model 1 such as figure 1 In a, the production includes the following steps:

[0040] (1) Formation preparation

[0041] Choose Gansu sandy soil as the formation, weigh 1.23kg, and bury it in a cylinder with a hole at the bottom and a diameter of 18.50cm. The height of the formation is 3.5cm, and the dry density is controlled at 1.31g / cm 3 .

[0042] (2) Culture of bacteria

[0043] The medium components of Bacillus pasteurianus are: 20g / L yeast extract, 10g / L NH 4 Cl, 2.4g / L NiCl2 , 1g / L MnSO 4 , using 0.1g / L NaOH solution to adjust the pH of the medium to 9, mix it evenly with a magnetic stirrer, and then place it in a high-temperature autoclave at 120°C for 30 minutes; 7 ~10 9 cells / mL were inoculated into the culture medium, placed in a constant temperature shaking incubator, and cultured at 30°C and 100r / min for 24h for later use...

Embodiment 3

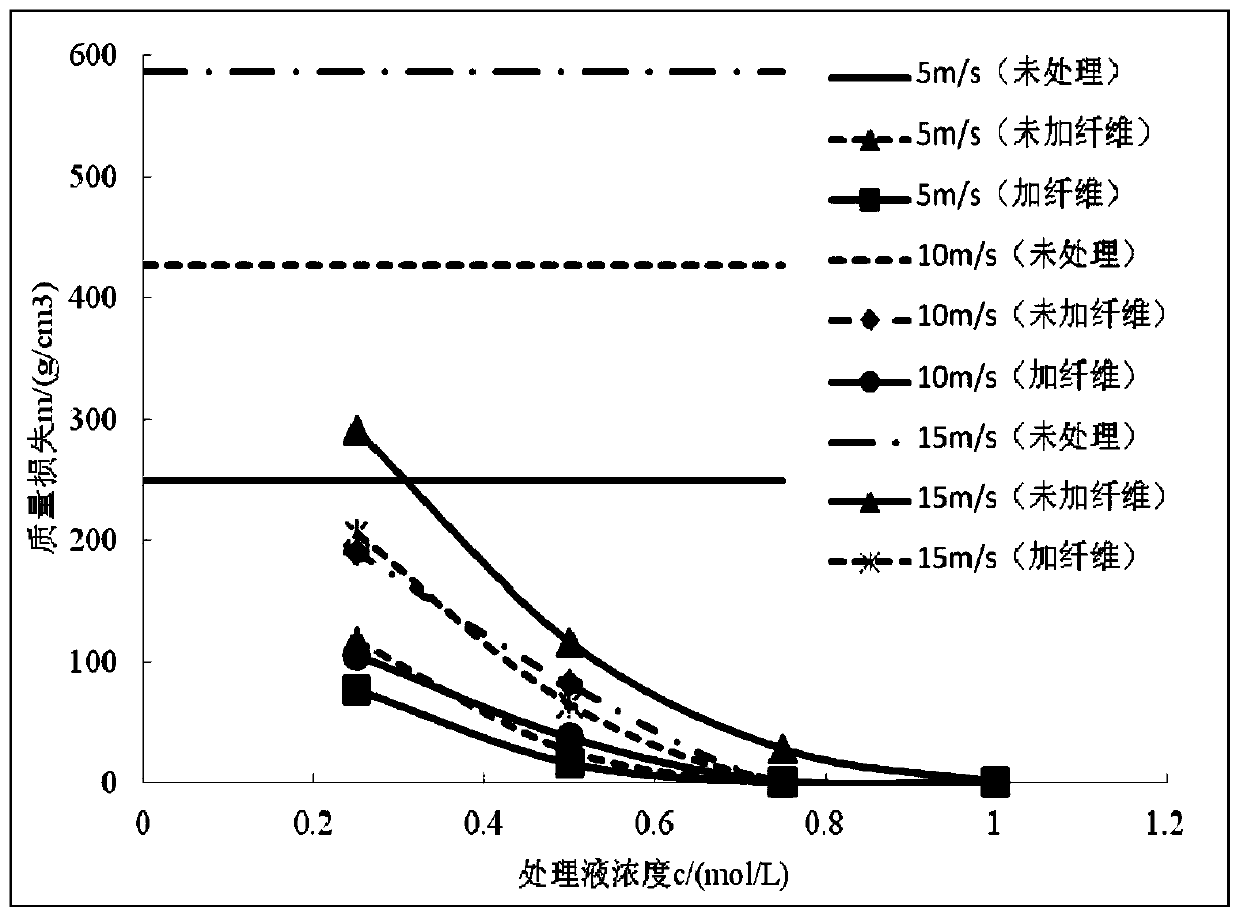

[0058] According to the test variables: (1) wind speed; (2) fiber; (3) treatment liquid concentration, a total of 36 working conditions were used to prepare the formation to be treated.

[0059] Weigh 2.0kg of sand and put it in a cuboid model box with a length of 24cm, a width of 17cm, and a height of 4cm, and control the dry density of the formation to 1.23g / cm 3

[0060] Prepare 4 kinds of CaCl according to the test variable treatment solution concentration 2 Treatment solution in equimolar ratio to urea, CaCl 2 The concentrations are 0.25mol / L, 0.5mol / L, 0.75mol / L, and 1mol / L, respectively.

[0061] The bacteria solution with an activity higher than 0.2mS / cm / min is selected and mixed with the treatment solution in an equimolar ratio to prepare the microbial reinforcement solution.

[0062] Put the reinforcement liquid in the watering can, and the amount of spraying at one time is 4L / m 2 , to ensure that the sprayed liquid is always in the form of mist, a total of 3 spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com