Side-chain type liquid crystal polymer liquid crystal physical gel material and preparation method thereof

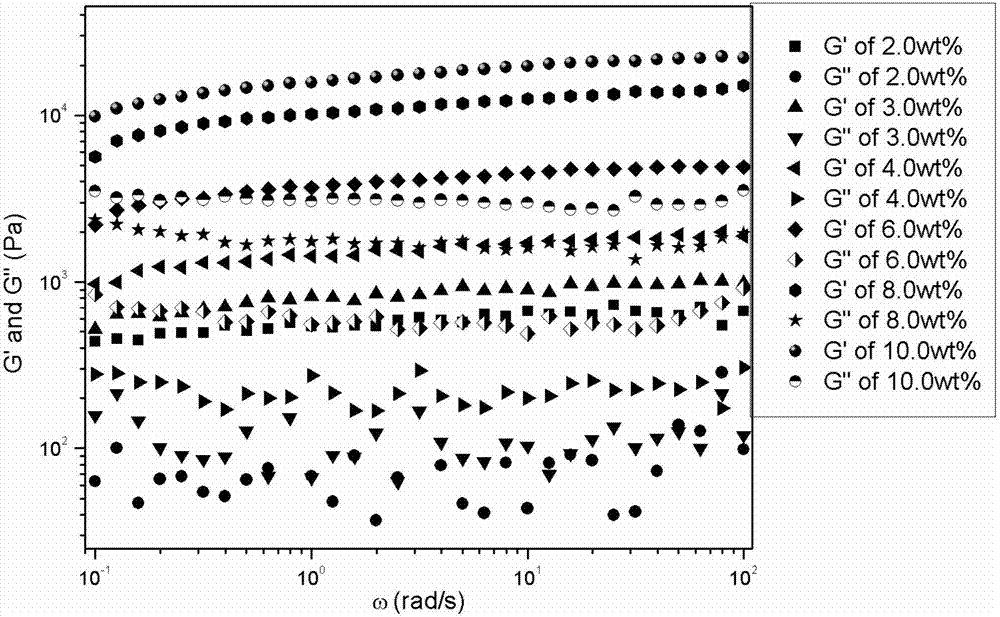

A side-chain liquid crystal and physical gel technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of low strength, high addition amount, poor self-support, etc., and achieve high modulus, high content and thermal stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

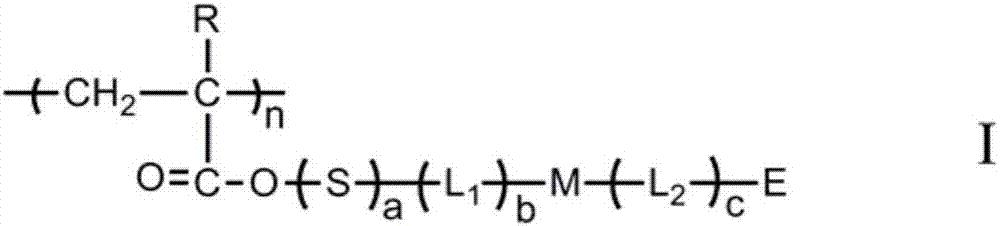

[0033] Take a clean polymer glass tube of 20mm×200mm, add 2.0g (7.60mmol) 4'-methacryloyloxy-4-cyanobiphenyl (MACB) into it, and then add 0.01g / ml of AIBN solution 658.4ul (3.80×10 - 2 mmol), then add refined DMF3.6g, freeze and evacuate, after repeating three times, seal the tube under vacuum, then put the polymerization tube into a constant temperature oil bath at 70°C to carry out polymerization reaction, after the polymerization is completed (by polymerization The viscosity of the system is judged) Put the polymerization tube into cold hydrazine to cool down, so that the polymerization reaction is terminated. Afterwards, the polymer solution was diluted with DMF, and the polymer solution was slowly added to 500ml of ethanol under stirring, precipitated, centrifuged, and vacuum-dried to obtain the target polymer PMACB 1.9g, with a conversion rate of 95%, and a molecular weight of 5.24×10 4 , whose structural formula is:

[0034]

[0035] Weigh 4'-n-pentyl-4-cyanobiph...

Embodiment 2

[0038] Take a clean polymeric glass tube of 20mm×200mm, add 2.0g (8.02mmol) 4'-acryloyloxy-4-cyanobiphenyl (ACB) into it, and then add 0.01g / ml of AIBN solution 658.42ul (4.01×10 - 2 mmol), then add refined DMF3.6g, freeze and evacuate, repeat three times, seal the tube under vacuum, then put the polymerization tube into a constant temperature oil bath at 70°C to carry out polymerization reaction, after the polymerization is completed (by polymerization The viscosity of the system is judged) Put the polymerization tube into cold hydrazine to cool down, so that the polymerization reaction is terminated. Afterwards, the polymer solution was diluted with DMF, and the polymer solution was slowly added to 500ml of ethanol under stirring, precipitated, centrifuged, and vacuum-dried to obtain the target polymer PACB1.94g, the conversion rate was 97%, and the molecular weight was 4.92×10 4 , whose structural formula is:

[0039]

[0040] Weigh liquid crystal small molecule 4'-n-...

Embodiment 3

[0043] Side chain type liquid crystal polymer used is the same as embodiment 1

[0044] Weigh liquid crystal small molecule 4'-n-pentyl-4-cyanobiphenyl (5CB) 4g, add in 25mm * 40mm sample bottle, then accurately weigh the gel factor PMACB, make it 4.0% by mass, heat Stir until completely dissolved, and cool naturally to obtain a liquid crystal physical gel material after the mixture is clarified.

[0045] The liquid crystal physical gel material obtained in this example has a gel disassociation temperature of 82°C and a gel-sol temperature of 86°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com