Preparation method of wheat protein fibers

A wheat protein fiber and glutenin technology is applied in the field of wheat protein resource utilization, which can solve the problems of influence and harm, and achieve the effects of expanding utilization space, low price, and improving breaking strength and elongation at break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

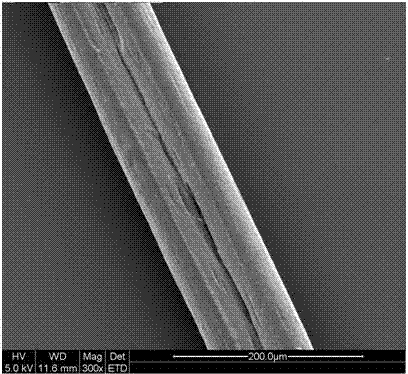

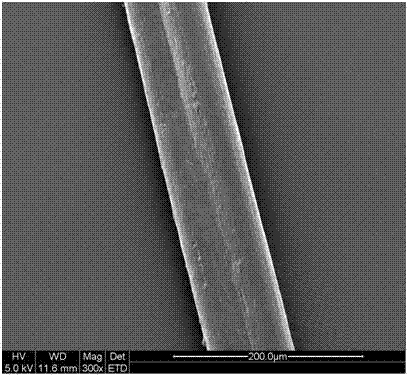

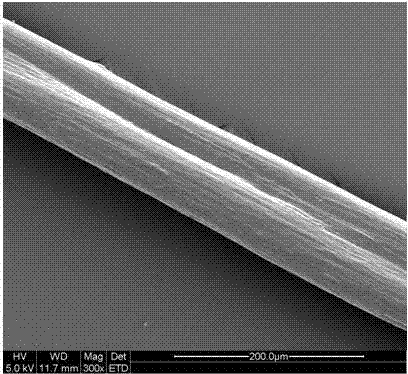

Image

Examples

Embodiment 1

[0021] Mix gluten powder and 65% ethanol solution at a solid-liquid ratio of 1:30, shake and extract at 50°C for 3 h, centrifuge, take the supernatant for rotary evaporation, and freeze-dry to obtain gliadin; The precipitate after gliadin was mixed with water at a material-liquid ratio of 1:15, the pH was adjusted to 11.5, shaken and extracted at 60°C for 3 h, centrifuged, and absolute ethanol was added to the supernatant to prepare a 65% ethanol solution. And adjust the pH to 7, centrifuge overnight at 4°C, wash the precipitate with distilled water three times, and freeze-dry to obtain glutenin; prepare 3% gliadin solution, add 0.5% gliadin mass in ethyl alcohol at 40°C acid anhydride, keep the pH at 8.0~8.5, keep stirring and reacting for 0.5 h, add distilled water after the reaction, centrifuge and wash 3 times, and freeze-dry to obtain acetylated gliadin; the acetylated gliadin and glutenin obtained after freeze-drying Mix according to the ratio of 3:1, use equal mass of 0...

Embodiment 2

[0023] Mix gluten powder and 65% ethanol solution at a solid-liquid ratio of 1:30, shake and extract at 50°C for 3 h, centrifuge, take the supernatant for rotary evaporation, and freeze-dry to obtain gliadin; the extracted wheat The precipitate after gliadin was mixed with water at a material-to-liquid ratio of 1:15, adjusted to pH 11.5, shaken and extracted at 60°C for 3 h, centrifuged, and absolute ethanol was added to the supernatant to prepare a 65% ethanol solution. And adjust the pH to 7, centrifuge overnight at 4°C, wash the precipitate with distilled water three times, and freeze-dry to obtain glutenin; prepare 5% gliadin solution, add 2% gliadin mass in ethyl alcohol at 40°C acid anhydride, keep the pH at 8.0~8.5, keep stirring and reacting for 0.5 h, add distilled water after the reaction, centrifuge and wash 3 times, and freeze-dry to obtain acetylated gliadin; the acetylated gliadin and glutenin obtained after freeze-drying Mix according to the ratio of 2:1, use eq...

Embodiment 3

[0025]Mix gluten powder and 65% ethanol solution at a solid-liquid ratio of 1:30, shake and extract at 50°C for 3 h, centrifuge, take the supernatant for rotary evaporation, and freeze-dry to obtain gliadin; the extracted wheat The precipitate after gliadin was mixed with water at a material-to-liquid ratio of 1:15, adjusted to pH 11.5, shaken and extracted at 60°C for 3 h, centrifuged, and absolute ethanol was added to the supernatant to prepare a 65% ethanol solution. And adjust the pH to 7, centrifuge overnight at 4°C, wash the precipitate with distilled water three times, and freeze-dry to obtain glutenin; prepare 5% gliadin solution, add 0.5% gliadin mass in ethyl alcohol at 40°C acid anhydride, keep the pH at 8.0~8.5, keep stirring and reacting for 0.5 h, add distilled water after the reaction, centrifuge and wash 3 times, and freeze-dry to obtain acetylated gliadin; the acetylated gliadin and glutenin obtained after freeze-drying Mix at a ratio of 3:1, use equal mass of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com