Semi-coke powder gasification and combustion system

A combustion system and technology of blue charcoal powder, applied in combustion methods, combustion equipment, block/powder fuel preparation, etc., can solve the problems of blue charcoal powder pollution, non-combustible combustion efficiency, etc., to reduce exhaust gas pollution problems, structure Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

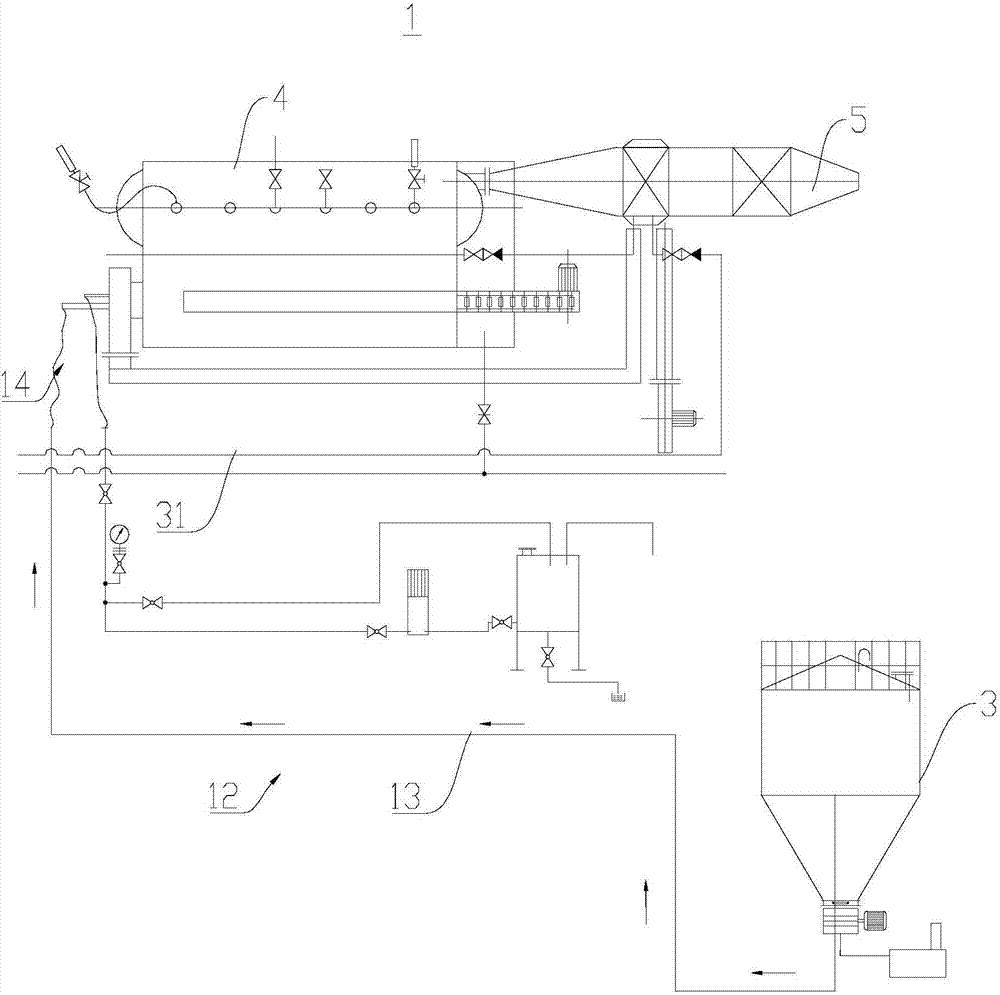

[0045] Please refer to figure 1 , with reference to Figure 2 to Figure 7 , The present embodiment provides a blue charcoal powder gasification combustion system 1, which is mainly used for the combustion of blue charcoal powder fuel, and solves the problem that blue charcoal powder is not easy to burn and easily causes environmental pollution due to its high ignition point.

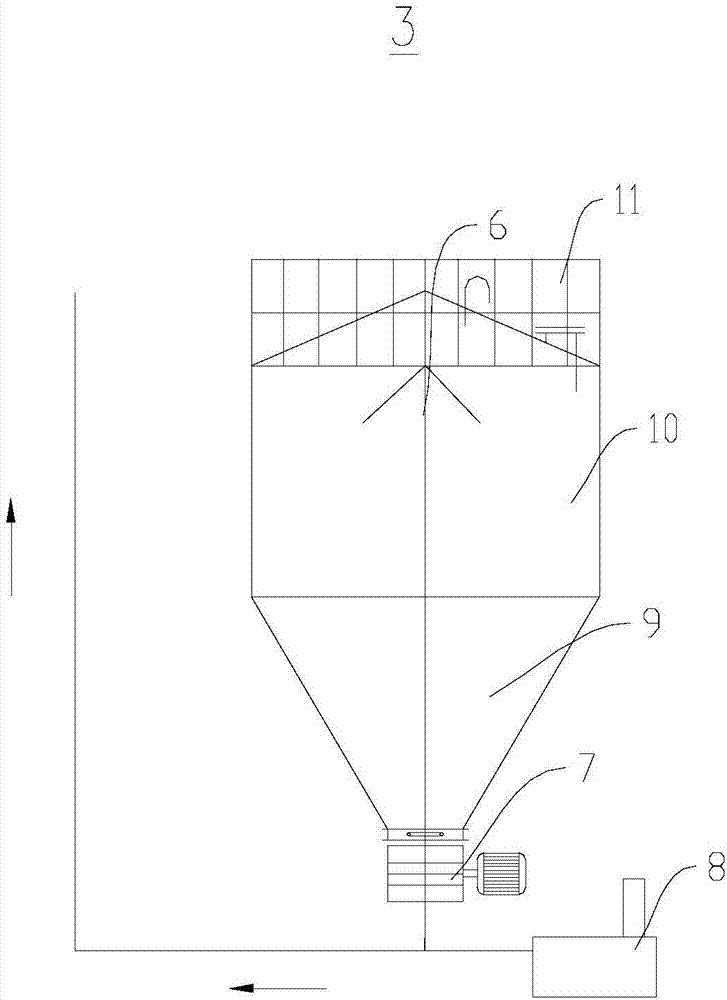

[0046] The blue charcoal powder gasification combustion system 1 includes a raw material supplier 2, a blue charcoal powder processing bin 3, a special gasification burner 4 for blue charcoal powder, and a recovery mechanism 5; the raw material supplier 2 is connected with the blue charcoal powder processing bin 3, One end of powder-specific gasification burner 4 is connected with one end of blue charcoal powder processing bin 3, and the other end is connected with recovery mechanism 5.

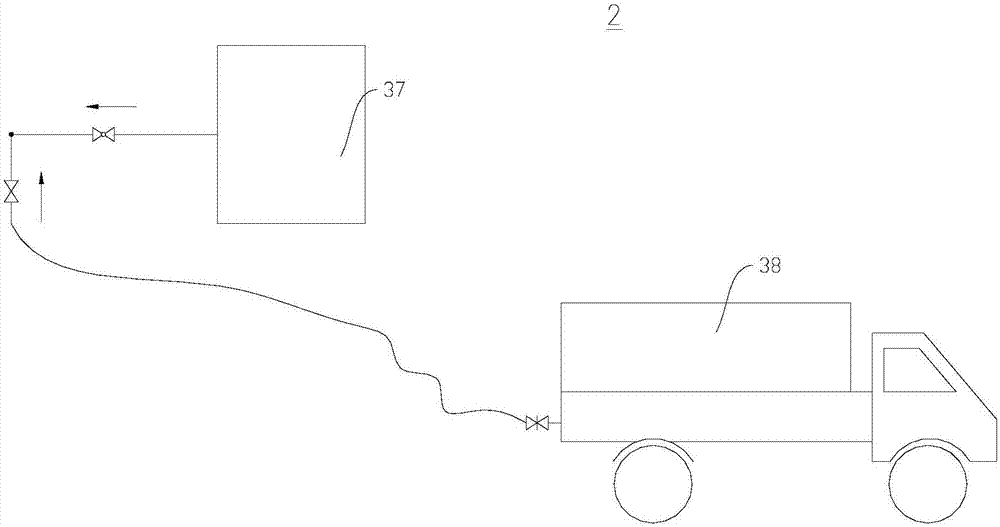

[0047] Please refer to figure 1 and figure 2 , the raw material supplier 2 is mainly used for the supply of semi-...

no. 2 example

[0058] Please refer to Figure 8 and Figure 9 , with reference to figure 1 , This embodiment provides another blue coke powder gasification combustion system 1 , which differs from the first embodiment in that the blue coke powder gasification combustion system 1 also includes a water supply device 28 and a sub-cylinder 29 .

[0059] The water supply device 28 includes a soft water tank 39 and a water treatment device 40. The soft water tank 39 is connected to the water treatment device 40 through a connecting pipe, and the water treatment device 40 is connected to the purification tank 22 through a water pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com