Method for producing compound micro-ecological active biological feed for ruminants by utilizing waste mushroom residues

A technology of compound microecology and ruminants, applied in the field of ruminant biological feed, can solve the problems of polluting the ecological environment, waste of agricultural organic resources, lack of scientific methods for high value-added reuse of mushroom residues, etc., to achieve efficient utilization, less The incidence of disease, the effect of prevention and treatment of digestive system diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

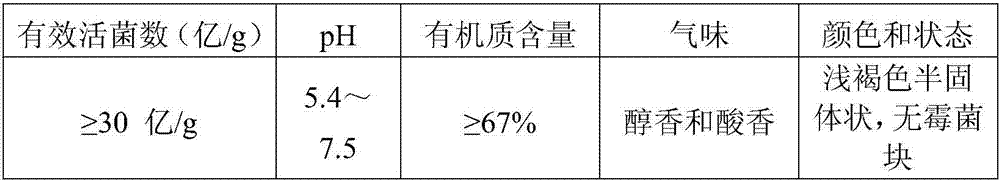

Examples

Embodiment 1

[0015] (1). Mechanically or manually crush the non-polluting mushroom dregs produced after harvesting edible fungi into pieces of about 0.5mm×0.5mm×0.5mm.

[0016] (2). Add 40% weight of crop straw powder (1mm × 1mm × 1mm) to the processed mushroom dregs in step (1), stir the above-mentioned mushroom dregs and crop straw powder mixture with tap water, and the final material has a water content of about 60%. .

[0017] (3). Cellulase-producing bacteria, protease-producing bacteria, lipase-producing bacteria, amylase-producing bacteria, chitinase-producing bacteria and lactic acid bacteria are activated and expanded step by step to prepare bacterial agents. The weight ratio of cellulase-producing bacteria, protease-producing bacteria, lipase-producing bacteria, amylase-producing bacteria, chitinase-producing bacteria and lactic acid bacteria in the composite bacterial agent is 3:3:1:1:2:2, which not only has good Fermentation effect, and contains beneficial bacteria that are be...

Embodiment 2

[0022] (1). Mechanically or manually crush the non-polluting mushroom dregs produced after harvesting edible fungi into pieces of about 0.5mm×0.5mm×0.5mm.

[0023] (2). Add 40% weight of crop straw powder (1mm × 1mm × 1mm) to the processed mushroom dregs in step (1), stir the above-mentioned mushroom dregs and crop straw powder mixture with natural water, and the final material has a water content of about 60 %.

[0024] (3). Cellulase-producing bacteria, protease-producing bacteria, lipase-producing bacteria, amylase-producing bacteria, chitinase-producing bacteria and lactic acid bacteria are activated and expanded step by step to prepare bacterial agents. The weight ratio of the compound bacterial agent cellulase-producing bacteria, protease-producing bacteria, lipase-producing bacteria, amylase-producing bacteria, chitinase-producing bacteria and lactic acid bacteria is 3:3:1:1:2:2,

[0025] (4). The composite enzyme-producing microbial bacterial agent prepared in step (3...

Embodiment 3

[0029] (1). Mechanically or manually crush the mushroom dregs produced after harvesting edible fungi into pieces of about 0.5mm×0.5mm×0.5mm.

[0030] (2). Add 40% crop stalk powder (1mm×1mm×1mm) to the mushroom dregs treated in step (1), stir the above-mentioned mushroom dregs and crop straw powder mixture with natural water, and the final material has a water content of about 60 %.

[0031] (3). Cellulase-producing bacteria, protease-producing bacteria, lipase-producing bacteria, amylase-producing bacteria, chitinase-producing bacteria and lactic acid bacteria are activated and expanded step by step to prepare bacterial agents. The weight ratio of the compound bacterial agent cellulase-producing bacteria, protease-producing bacteria, lipase-producing bacteria, amylase-producing bacteria, chitinase-producing bacteria and lactic acid bacteria is 3:3:1:1:2:2,

[0032] (4). The enzyme-producing mixed microbial bacterial agent prepared in step (3) is inoculated onto the mixture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com