Composite starch styptic powder

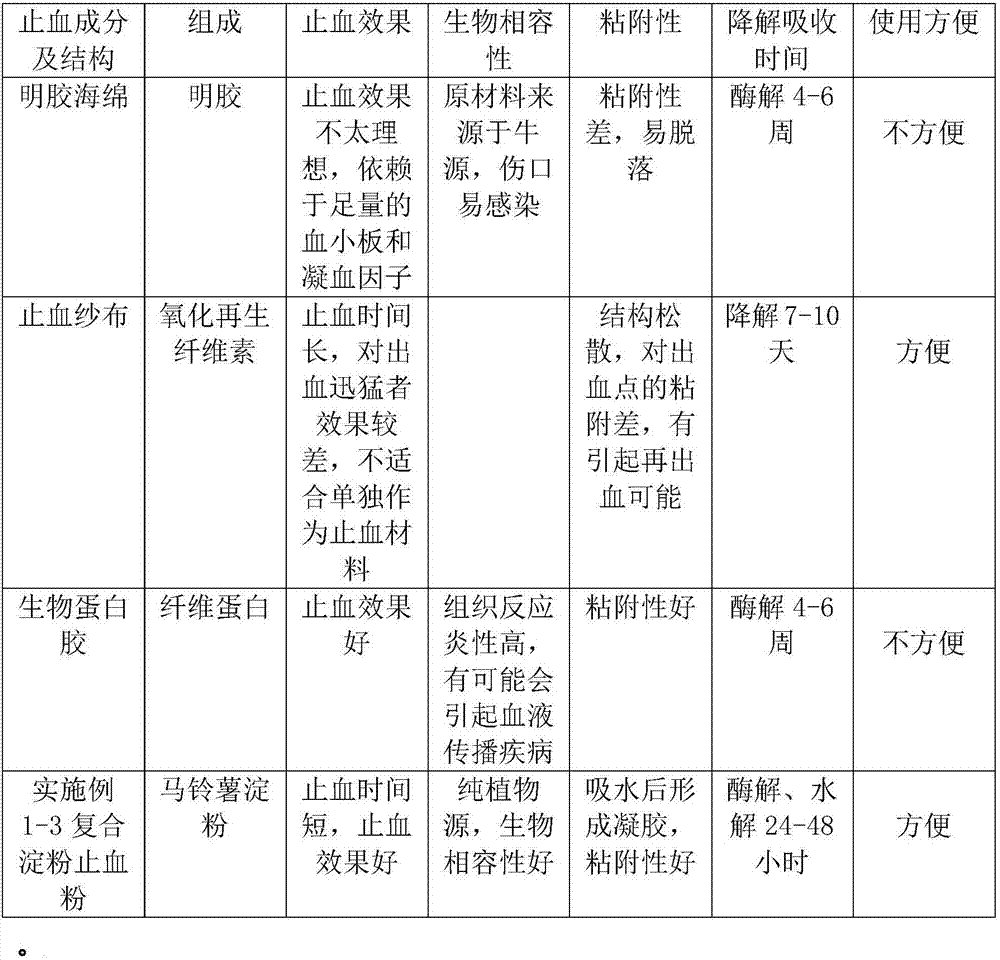

A technology of compound starch and hemostatic powder, applied in the field of medical supplies, can solve the problems of limited utilization rate, slow water absorption of starch microspheres, and low water absorption rate, and achieve the effect of accelerating activation and shortening coagulation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

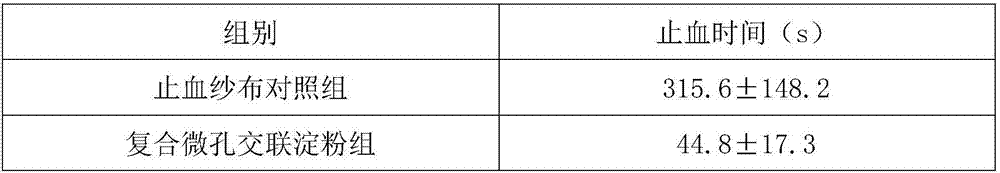

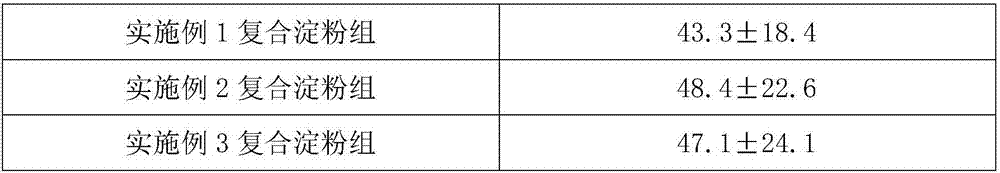

Examples

Embodiment 1

[0025] The preparation method of the composite starch hemostatic powder of this embodiment is as follows:

[0026] ① Take 10g of starch and add 200ml of purified water and stir until gelatinization, then add 10g of sodium carboxymethyl cellulose, and use NaOH to adjust the pH to 7.

[0027] ②Add 750ml of liquid paraffin to the reaction kettle, and after the temperature is raised to 75°C, add 20ml of a mixture of Span 80 and 30ml Tween 80.

[0028] ③Mix ① into ② and react for 8h, then take the material.

[0029] ④Add absolute ethanol to separate materials, pour off the upper oil phase, repeat washing and suction filtration with absolute ethanol 3 times, dry in an oven, grind, sieve, pack, and sterilize.

Embodiment 2

[0031] The preparation method of the composite starch hemostatic powder of this embodiment is as follows:

[0032] ① Take 10g of starch and add 800ml of purified water and stir until gelatinization, then add 0.1g of sodium alginate, and adjust the pH to 9 with NaOH.

[0033] ② Put 150ml of vegetable oil into the reaction kettle, and when the temperature reaches 65°C, add 2ml of Span 80 and 3ml of Tween 80 mixture.

[0034] ③ Mix ① into ② and react for 16 hours, and then take the material.

[0035] ④Add absolute ethanol to separate materials, pour off the upper oil phase, repeat washing and suction filtration with absolute ethanol 3 times, dry in an oven, grind, sieve, pack, and sterilize.

Embodiment 3

[0037] The preparation method of the composite starch hemostatic powder of this embodiment is as follows:

[0038] ① Take 10g of starch and add 500ml of purified water and stir until gelatinization, then add 5g of sodium carboxymethyl cellulose, and use NaOH to adjust the pH to 11.

[0039] ②Put 500ml of vegetable oil into the reaction kettle, and when it is heated to 70°C, add 10ml of a mixture of Span 80 and 10ml of Tween 80.

[0040] ③Mix ① into ② and react for 24h, then take the material.

[0041] ④Add absolute ethanol and ethyl acetate to separate the materials, pour off the upper oil phase, repeat washing and suction filtration with absolute ethanol 3 times, dry in an oven, grind, sieve, pack, and sterilize.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com