Improved process for preparing alpha-aluminum hydride

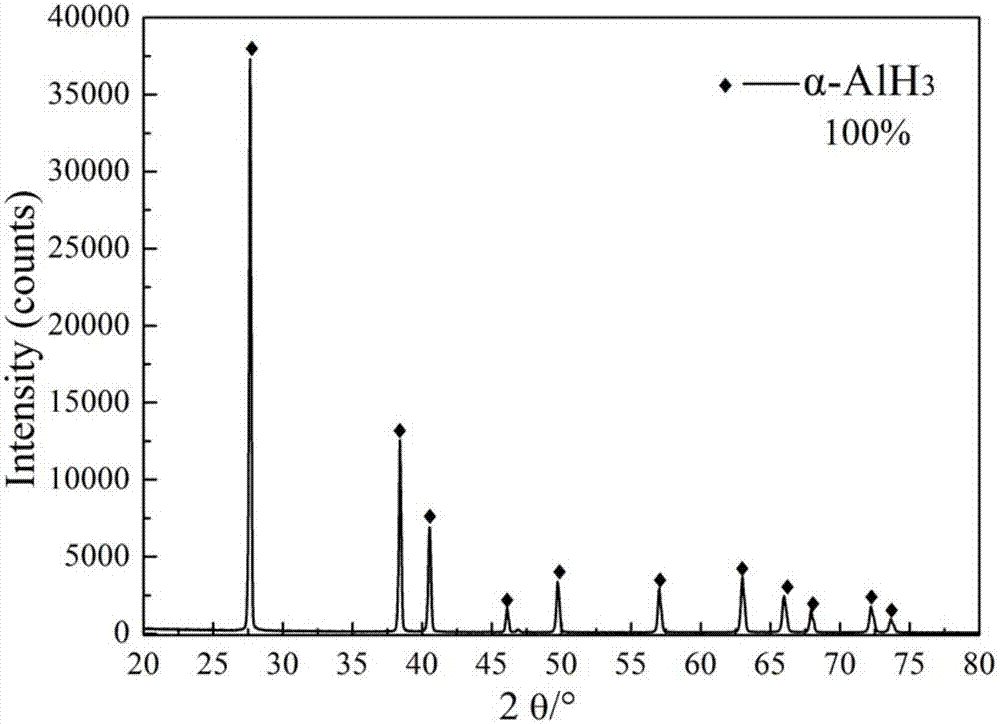

A technology of aluminum trihydride and lithium aluminum hydride, applied in metal hydrides, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of complicated preparation of AlH3, complicated separation and purification of reaction products, unstable hydrogen release performance, etc. The reaction conditions are easy to control, the safety is satisfied, and the price is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 An improved process for preparing α-aluminum hydride, comprising the following steps:

[0021] (1) Refining with anhydrous ether, specifically: take 40g of sodium metal and cut it into thin slices and place it in a reaction vessel filled with 10L of industrial ether, reflux at 30°C for 50min, and then collect the distilled fraction at 36-42°C and seal it spare.

[0022] (2) Refining toluene, specifically: take 40g of sodium and cut it into thin slices and place it in a reactor containing 10L of industrial toluene, reflux at 120°C for 60min, then collect the distilled fractions at 108-128°C, seal and reserve .

[0023] (3) Lithium aluminum hydride refining, specifically: take 8000g of lithium aluminum hydride and add it to a 200L glass reactor, add 100L of refined anhydrous diethyl ether at the same time, stir, then add 30L of refined toluene, continue stirring evenly, and let stand for 12h , then filtered under reduced pressure, and the filtrate was disti...

Embodiment 2

[0027] Embodiment 2 An improved process for preparing α-aluminum hydride, comprising the following steps:

[0028] (1) Refining of anhydrous ether, specifically: take 80g of sodium metal and cut it into thin slices and place it in a reaction vessel filled with 10L of industrial ether, reflux at 50°C for 20min, and then collect the distilled fraction at 36-42°C and seal it spare.

[0029] (2) Toluene refining, specifically: take 80g of sodium and cut it into thin slices and place it in a reactor filled with 10L of industrial toluene, reflux at 140°C for 30min, then collect the distilled fractions at 108-128°C, seal and reserve .

[0030] (3) Lithium aluminum hydride refining, specifically: take 10,000g of lithium aluminum hydride and add it to a 200L glass reactor, add 80L of refined anhydrous ether at the same time, stir, then add 50L of refined toluene, continue stirring evenly, and let it stand for 24 hours , then filtered under reduced pressure, and the filtrate was disti...

Embodiment 3

[0034] Embodiment 3 An improved process for preparing α-aluminum hydride, comprising the following steps:

[0035] (1) Refining with anhydrous ether, specifically: take 60g of sodium metal and cut it into thin slices and place it in a reaction vessel filled with 10L of industrial ether, reflux at 40°C for 35min, and then collect the distilled fractions at 36-42°C and seal them spare.

[0036] (2) Toluene refining, specifically: take 60g of sodium and cut it into thin slices and place it in a reactor filled with 10L of industrial toluene, reflux at 130°C for 45min, then collect the distilled fractions at 108-128°C, seal and reserve .

[0037] (3) Lithium aluminum hydride refining, specifically: take 9000g of lithium aluminum hydride and add it to a 200L glass reactor, add 90L of refined anhydrous ether at the same time, stir, then add 40L of refined toluene, continue stirring evenly, and let stand for 18h , then filtered under reduced pressure, and the filtrate was distilled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com