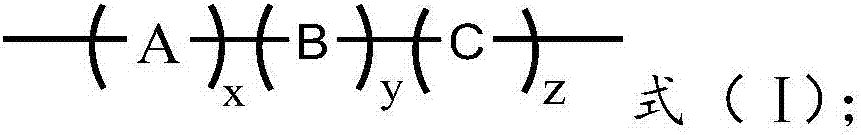

Water-in-oil association type acidification and concentration thickening agent and preparation method thereof

A thickening agent and associative type technology, which is applied in the field of water-in-oil associative acidified concentrated thickening agent and its preparation, and can solve the problems of powdered fish eyes, affecting solution performance, jelly agglomeration and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides a method for preparing the above-mentioned water-in-oil association type acidified thickening agent, comprising the following steps:

[0061] A) mixing and stirring the dispersed phase, the dispersion medium and the composite emulsifier to obtain a water-in-oil emulsion;

[0062] B) adding a hydrophobic association polymer acid thickener to the water-in-oil emulsion, mixing and stirring to obtain a water-in-oil association type acidified thickener.

[0063] In the present invention, firstly, the dispersed phase, the dispersion medium and the composite emulsifier are mixed and stirred to obtain a water-in-oil emulsion, and the temperature of mixing and stirring is 35-70° C., preferably 40-60° C., more preferably 45-55° C.; the mixing The stirring speed is 300-800rmp, preferably 300-600rmp; the mixing and stirring time is 20-40min.

[0064] After the water-in-oil emulsion is obtained, a hydrophobic association polymer acid thickener is...

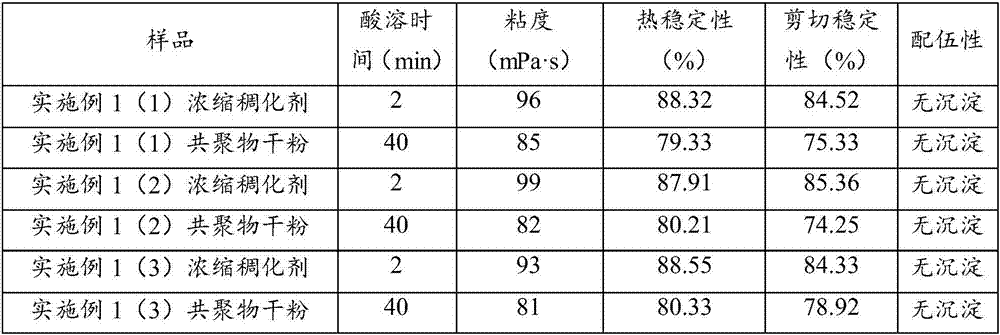

Embodiment 1

[0069] Preparation of water-in-oil (W / O) associative acidified concentrated thickener (compound emulsifier: propylene glycol monostearate BPMS+Pingpinga O O-5)

[0070] (1) A kind of W / O associative type acidification concentrated thickener, comprises the component of following mass percentage:

[0071] 0# diesel oil 38.22%, water 38.22%, hydrophobic association polymer acid thickener 20%, propylene glycol monostearate BPMS 2.85%, Pingpingjia 0 O-5 0.71%;

[0072] The hydrophobic association polymer acid thickener is acrylamide / acryloxytetradecyl quaternary ammonium salt / 2-acrylamide-2-methylpropanesulfonate copolymer, and the compound The emulsifier is BPMS and O-5 (ratio 4:1), and the preparation steps are as follows:

[0073] At 40°C, control the mass ratio of oil to water to 5:5, mix and emulsify 382.2g diesel, 382.2g water, 28.5g BPMS, 7.1g O-5, and stir at 600rmp for 30min to form a stable water-in-oil emulsion , and finally add 200g of hydrophobic association polymer ...

Embodiment 2

[0083] Preparation of water-in-oil (W / O) associative acidified thickener (compound emulsifier is propylene glycol monolaurate BPML+polyoxyethylene castor oil EL-20)

[0084] (1) A kind of W / O associative type acidification concentrated thickener, comprises the component of following mass percentage:

[0085] 0# diesel oil 42.86%, water 28.57%, hydrophobic association polymer acid thickener 25%, propylene glycol monolaurate BPML 2.14%, polyoxyethylene castor oil EL-20 1.43%;

[0086] Described hydrophobic association polymer acid thickener is acrylamide / acryloxy nonyl quaternary ammonium salt / N-vinyl-2-pyrrolidone copolymer, and described composite emulsifier is BPML and EL-20 ( Ratio 3:2), the preparation steps are as follows:

[0087] At 50°C, control the mass ratio of oil to water to 6:4, mix 428.6g diesel, 285.7g water, 21.4g BPML, and 14.3g EL-20 to emulsify evenly, stir at 600rmp for 30min to form a stable water-in-oil emulsion , and finally add 250g of hydrophobic asso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com