Catalyst for catalytic decomposition of N2O at medium and low temperature, preparation method and application

A low-temperature catalysis and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, separation method, etc. Active oxide sintering and other issues to achieve superior low-temperature catalytic activity, maintain continuous adsorption and desorption, and stable configuration characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

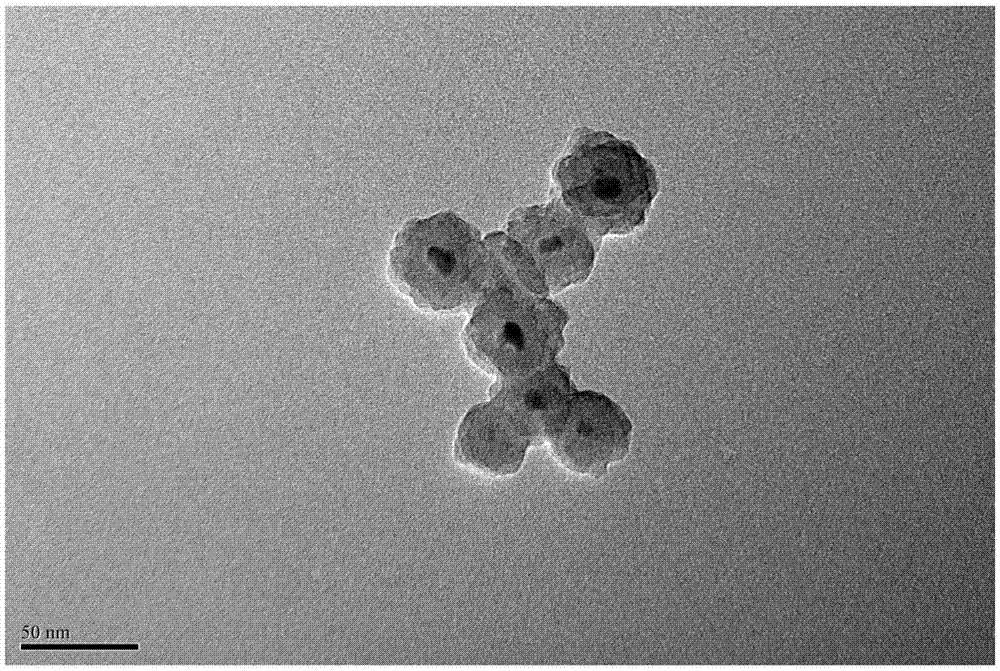

[0040] (a) Weigh 1.82g Co(NO 3 ) 2 ·6H 2 O, 1.61g Co(acac) 2 (The total amount of Co ions is 0.0125mol, and the molar ratio of inorganic salt to organic salt is 1:1) and 35.1g (0.25mol) of hexamethylenetetramine are added to 1L of ethanol in a volume ratio of 2:1 and stirred Mix, and add 3.43 g of polyvinylpyrrolidone to the mixed solution to complete dissolution. (b) Continue to add 15 mL of 3wt% H to the mixed solution 2 O 2 After the solution system gradually turns black, the temperature is raised to 60° C. and vigorously stirred for 72 hours to obtain a highly uniformly dispersed nanoparticle suspension of cobalt tetraoxide. (c) Add 0.014g Zr(NO 3 ) 2 ·5H 2 O was dissolved in 210 mL of ethanol, and 30 mL of ethyl orthosilicate was added to it to obtain a mixed solution of ethyl orthosilicate zirconium nitrate in ethanol. (d) Add dropwise the mixed solution prepared in step (c) in situ to the suspension prepared in step (b), and add 10 mL of ammonia water, and continue the r...

Embodiment 2

[0046] (a) Weigh 1.19g CoCl 2 ·6H 2 O, 2.49g Co(Ac) 2 ·4H 2 O (the amount of Co ion total substance is 0.015mol, the mole fraction ratio of inorganic salt and organic salt is 0.5:1) and 42.2g (0.3mol) hexamethylenetetramine are added to 1L of ethanol aqueous solution with a volume ratio of 2.5:1 Stir and mix, and add 3.66 g of polyvinylpyrrolidone to the mixed solution to complete dissolution. (b) Continue to add 20mL of 3wt% H to the mixed solution 2 O 2 The solution, after the solution system gradually turns black, the temperature is raised to 55° C. and vigorously stirred for 12 hours to obtain a highly uniformly dispersed Co3O4 nanoparticle suspension. (c) 0.32g Zr(NO 3 ) 2 ·5H 2 O was dissolved in 150 mL of ethanol, and 15 mL of ethyl orthosilicate was added thereto to obtain a mixed solution of ethyl orthosilicate zirconium nitrate in ethanol. (d) Add dropwise the mixed solution prepared in step (c) in situ to the suspension prepared in step (b), and add 20 mL of ammonia ...

Embodiment 3

[0051] (a) Weigh 1.82g Co(NO 3 ) 2 ·6H 2 O, 1.61g Co(acac) 2 (The total amount of Co ion is 0.0125mol, and the mole fraction ratio of inorganic salt and organic salt is 1:1) and 28.1g (0.2mol) of hexamethylenetetramine are added to 1L of ethanol in a volume ratio of 2:1 and stirred Mix, and add 3.43 g of polyvinylpyrrolidone to the mixed solution to complete dissolution. (b) Continue to add 18 mL of 3wt% H to the mixed solution 2 O 2 After the solution system gradually turns black, the temperature is increased to 70° C., and the mixture is vigorously stirred for 24 hours to obtain a highly uniformly dispersed Co3O4 nanoparticle suspension. (c) Add 0.25g Zr(NO 3 ) 2 ·5H 2 O was dissolved in 210 mL of ethanol, and 30 mL of ethyl orthosilicate was added to it to obtain a mixed solution of ethyl orthosilicate zirconium nitrate in ethanol. (d) Add dropwise the mixed solution prepared in step (c) to the suspension prepared in step (b), and add 15 mL of ammonia, and continue the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com