Harmless disposal method of waste incineration fly ash

A waste incineration fly ash and disposal method technology, applied to chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problem of increased chloride ion concentration at the kiln tail, difficulty in recovering cement from chloride salts, and overcapacity of cement and other problems, to achieve the effect of comprehensive treatment with low operating cost, obvious weight reduction rate, and no secondary environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

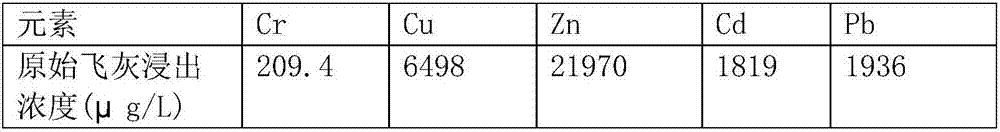

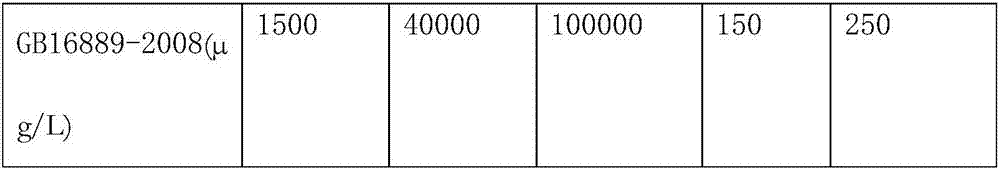

[0025] The test results of heavy metal leaching concentration in fly ash of a waste incineration plant are shown in Table 1. It can be seen that Cd and Pb seriously exceed the standard and belong to hazardous waste.

[0026] Table 1 Comparison of the leaching concentration of heavy metals in the original fly ash and the national standard

[0027]

[0028]

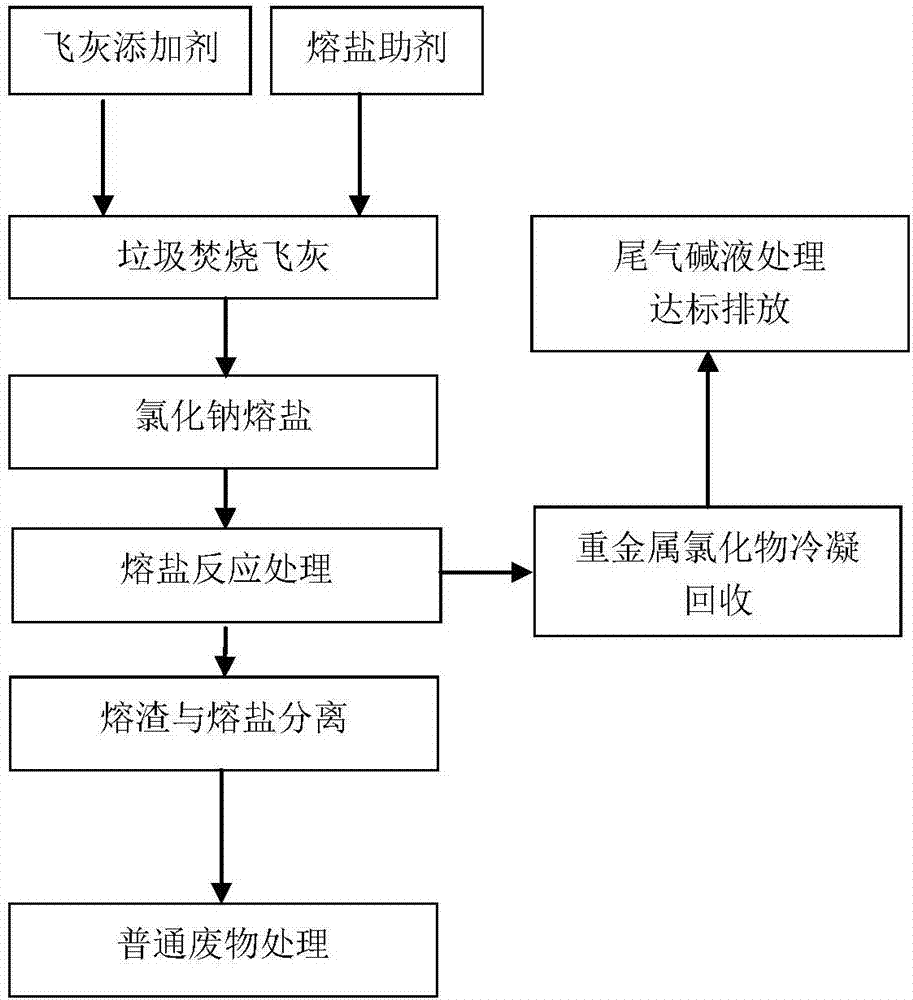

[0029] refer to figure 1 100 grams of waste incineration fly ash and 6 grams of molten salt additive calcium chloride were added to molten sodium chloride at 850 ° C for 3 hours to react. Discharge and settle at the bottom of molten sodium chloride, collect the fly ash and molten salt slag at the bottom and bury it, generate volatile gas during the reaction, collect the heavy metals through condensation, and discharge the rest of the gas;

[0030] The heavy metal leaching concentration of the fly ash molten salt slag is measured in Table 2 below, from which it can be seen that the fly ash molten salt slag has fully m...

Embodiment 2

[0034] Add 100 grams of waste incineration fly ash, 5 grams of fly ash additive silica fume, and 8 grams of molten salt additive calcium chloride into 900°C sodium chloride molten salt for 3 hours of reaction. The fly ash and molten salt slag generated during the reaction It is discharged from the molten sodium chloride and precipitated at the bottom of the molten sodium chloride, and the fly ash molten salt slag at the bottom is collected and then buried. The volatile gas generated during the reaction is collected by condensation to collect the heavy metals, and the rest of the gas is discharged;

[0035] The heavy metal leaching concentration of the fly ash molten salt slag is measured in Table 3 below. It can be seen from the table that the fly ash molten salt slag fully meets the pollutant control index requirements of the domestic waste landfill.

[0036] Table 3 Comparison of the leaching concentration of heavy metal ions after molten salt reaction treatment with the orig...

Embodiment 3

[0039] Add 100 grams of waste incineration fly ash, 10 grams of fly ash additive fly ash, and 5 grams of melt additive calcium chloride into molten sodium chloride salt at 1000 ° C for 1 hour, and the fly ash molten salt generated during the reaction The slag is discharged from the molten sodium chloride and precipitated at the bottom of the molten sodium chloride. The fly ash molten salt slag at the bottom is collected and then buried. The volatile gas generated during the reaction is collected by condensation to collect the heavy metals, and the rest of the gas is discharged. ;

[0040] The leaching concentration of heavy metals in fly ash molten salt slag is shown in Table 4 below, from which it can be seen that fly ash molten salt slag has fully met the requirements of pollutant control indicators for domestic waste landfills.

[0041] Table 4 Comparison of leaching concentration of heavy metal ions after molten salt reaction treatment with original fly ash and national st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com