Method for extracting rare earth from weathered crust strain amass type rare earth ore

A weathering crust leaching type, rare earth ore technology, applied in the direction of improving process efficiency, can solve the problems of inability to obtain products, good precipitation effect, reducing the purity of rare earth concentrate products, etc., to improve leaching rate, eliminate ammonia nitrogen pollution, The effect of increasing rare earth leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

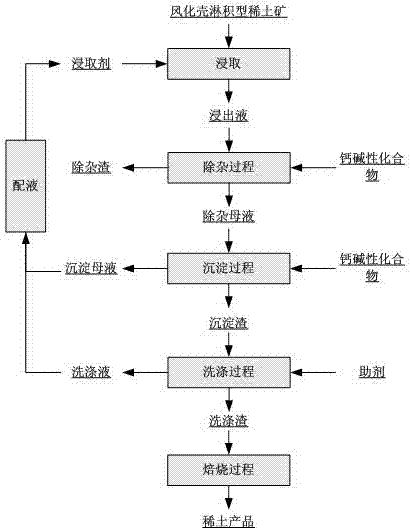

Image

Examples

Embodiment 1

[0037] Example 1: Magnesium sulfate solution was used to leaching weathering crust elution-type rare earth ore to obtain an aluminum content of 0.05 g / L and a rare earth content of 0.3 g / L (calculated as REO). Calcium oxide is added to the leaching solution, the pH of the solution is adjusted to 5.2 for impurity removal, and then the impurity removal residue and the impurity removal mother liquor are obtained by filtering and washing with water. Calcium oxide is added to the impurity removal mother liquor for precipitation, the temperature is 20°C, and the pH of the precipitation end point is controlled to be 8.5; then, the precipitation mother liquor and precipitation residue are obtained by filtering and washing with water. The precipitated residue is stirred and washed with polyaspartic acid additive solution, the total molar concentration of the additive is controlled to be 0.002mol / L, the liquid-solid ratio is 0.5:1, the temperature is 20°C, and the pH is 11.0; then solid-...

Embodiment 2

[0038] Example 2: The weathering crust leaching type rare earth ore was leached with a sulfate solution containing magnesium and sodium to obtain an aluminum content of 0.1 g / L and a rare earth content of 0.5 g / L (calculated as REO). Calcium hydroxide is added to the leaching solution, the pH of the solution is adjusted to 5.2 for impurity removal, and then the impurity removal residue and the impurity removal mother liquor are obtained by filtering and washing with water. Calcium hydroxide is added to the impurity removal mother liquor for precipitation, the temperature is 20°C, and the pH of the precipitation end point is controlled to be 8.5; then, the precipitation mother liquor and precipitation residue are obtained by filtering and washing with water. The precipitated residue is stirred and washed with polyacrylic acid additive solution, the total molar concentration of the additive is controlled to 0.002mol / L, the liquid-solid ratio is 0.5:1, the temperature is 20°C, and...

Embodiment 3

[0039] Example 3: The weathered crust leached type rare earth ore was leached with sulfate and chloride solutions containing magnesium and potassium to obtain an aluminum content of 0.3 g / L and a rare earth content of 2 g / L (calculated as REO). Calcium oxide is added to the leaching solution, the pH of the solution is adjusted to 5.4 for impurity removal, and then the impurity removal residue and the impurity removal mother liquor are obtained by filtering and washing with water. Calcium oxide is added to the impurity removal mother liquor for precipitation, the temperature is 40°C, and the pH of the precipitation end point is controlled to be 9; then the precipitation mother liquor and precipitation residue are obtained by filtering and washing with water. The precipitated residue is stirred and washed with a mixed additive solution of polyaspartic acid and sodium ethylenediamine tetramethylene pyridene phosphonate (molar ratio 0.5:1), and the total molar concentration of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com