Preparation method and application of ordered mesoporous titania-nanometer gold composite material

A technology of mesoporous titanium dioxide and composite materials, which is applied in the field of photocatalytic materials, can solve the problems such as the inability to meet the requirements of the oxidation half-reaction, and achieve the effect of improving the photocatalytic reduction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of ordered mesoporous titanium dioxide-nano gold composite material of the present invention, comprises steps as follows:

[0027] White ordered mesoporous titanium dioxide was prepared by solvent evaporation-induced self-assembly and two-step heat treatment;

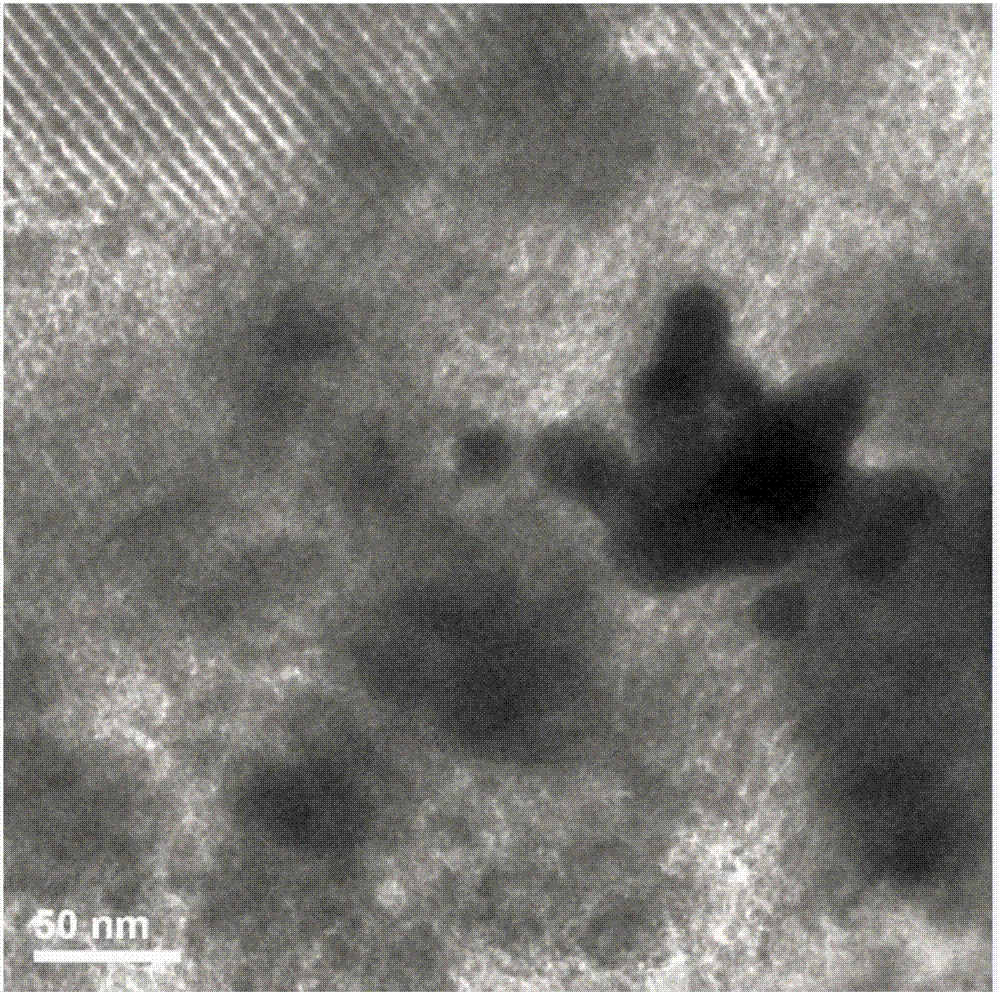

[0028] Gold nanoparticles are deposited inside the channels of ordered mesoporous titania by chemical reduction to obtain ordered mesoporous titania-nano-gold composites;

[0029] The mass fraction of gold nanoparticles in the ordered mesoporous titanium dioxide-nano gold composite material is 1-9%.

Embodiment 1

[0031] (11) The triblock copolymer F127 (molecular formula is PEO 106 -PPO 70 -PEO 10 ), water-soluble phenolic resin, concentrated hydrochloric acid and tetra-n-butyl titanate are dissolved in ethanol, and stirred evenly to form a wine-red transparent solution, and their mass ratio is triblock copolymer: water-soluble phenolic resin: concentrated hydrochloric acid: titanium Acid tetra-n-butyl ester=1:0.25:0.5:1.7;

[0032] (12) Transfer the solution prepared in step (11) to a flat-bottomed container, perform solvent evaporation at 25°C to induce self-assembly for 12 hours, and then thermally polymerize at 70°C for 12 hours to obtain a wine red film;

[0033] (13) The burgundy film obtained in step (12) is first kept at 350° C. for 3 h in an atmosphere tube furnace with nitrogen, and then kept at 400° C. for 2 h in an atmosphere tube furnace with air. Strictly controlled at 1°C / min, and finally white ordered mesoporous titanium dioxide powder is obtained;

[0034] (14) A c...

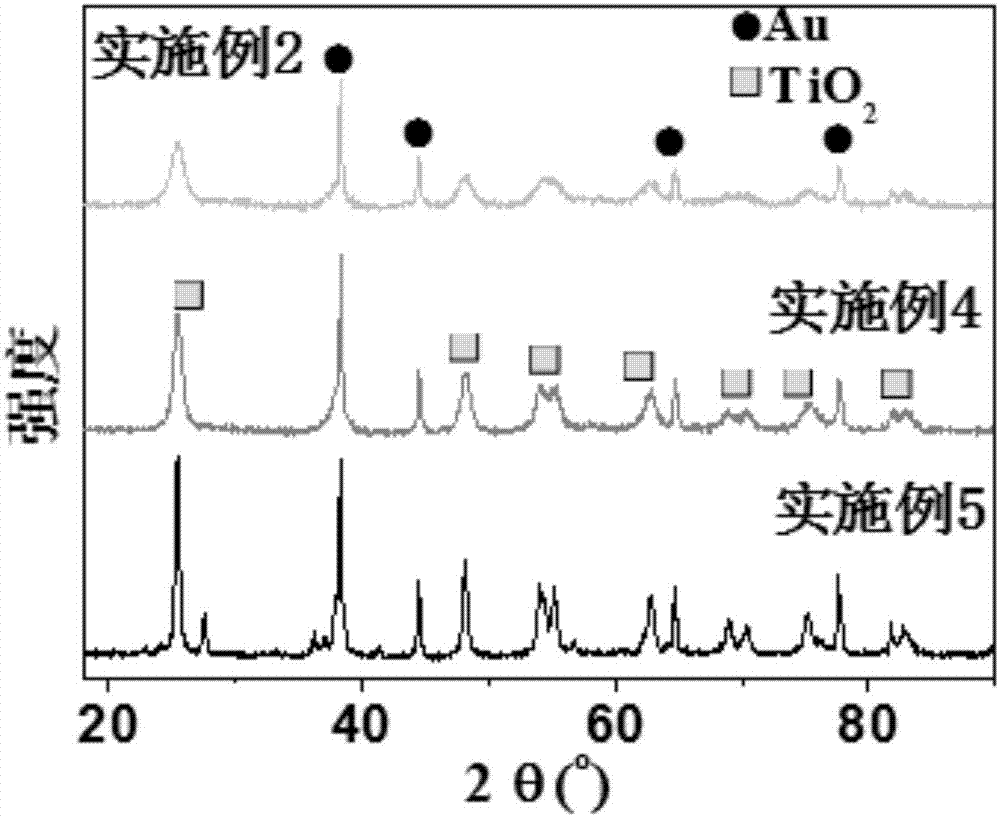

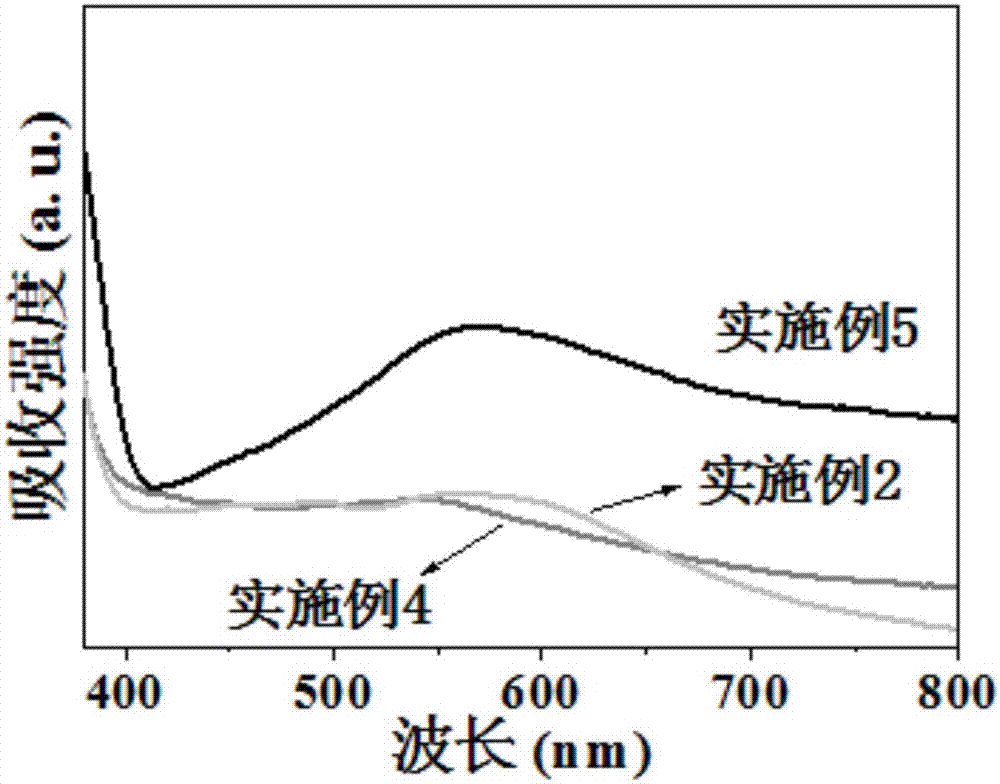

Embodiment 2

[0036] (21) The triblock copolymer F127 (molecular formula is PEO 106 -PPO 70 -PEO 10 ), water-soluble phenolic resin, concentrated hydrochloric acid and tetra-n-butyl titanate are dissolved in ethanol, and stirred evenly to form a wine-red transparent solution, and their mass ratio is triblock copolymer: water-soluble phenolic resin: concentrated hydrochloric acid: titanium Acid tetra-n-butyl ester=1:0.25:0.5:1.7;

[0037] (22) Transfer the solution prepared in step (21) to a flat-bottomed container, perform solvent evaporation at 40°C to induce self-assembly for 24 hours, and then thermally polymerize at 120°C for 24 hours to obtain a wine red film;

[0038] (23) The burgundy film obtained in step (22) is first kept at 350° C. for 5 hours in an atmosphere tube furnace with nitrogen, and then kept at 400° C. for 4 hours in an atmosphere tube furnace with air. Strictly controlled at 1°C / min, and finally white ordered mesoporous titanium dioxide powder is obtained;

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com