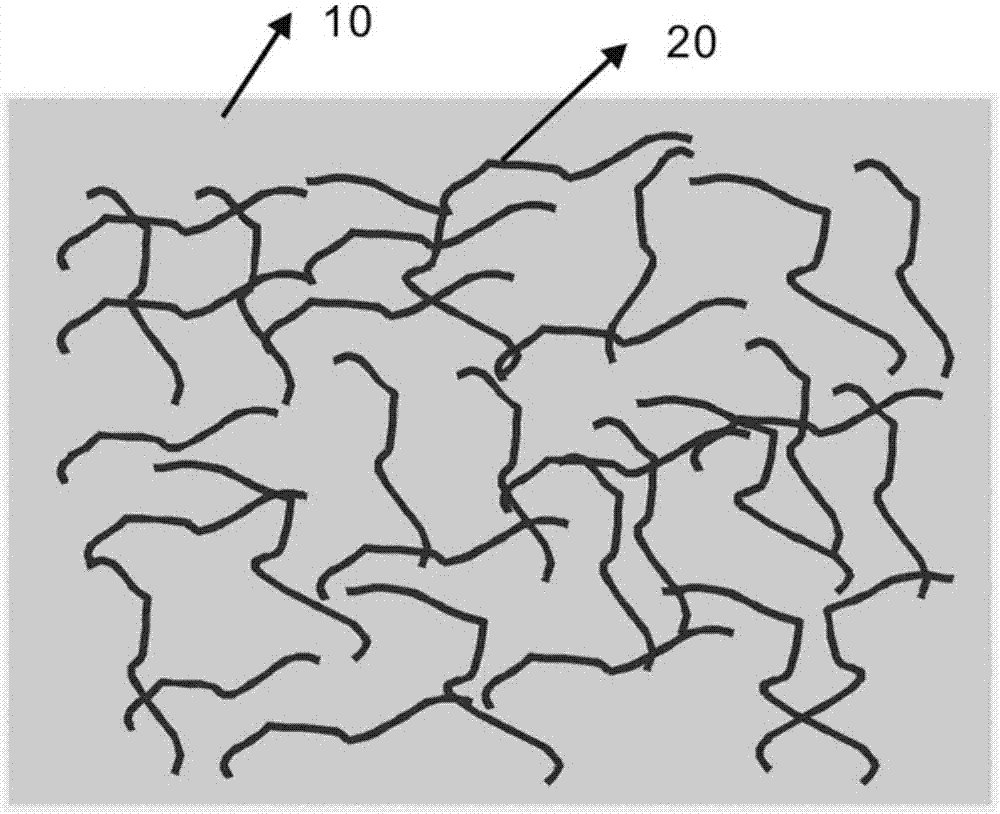

Boron nitride nanotube-nano-cellulose fiber composite material and preparation method thereof

A technology of boron nitride nanotubes and fiber composite materials, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of poor interaction force, limit the use of boron nitride nanotubes, and difficult to disperse, and achieve the preparation The effect of simple and gentle method, good dimensional stability and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

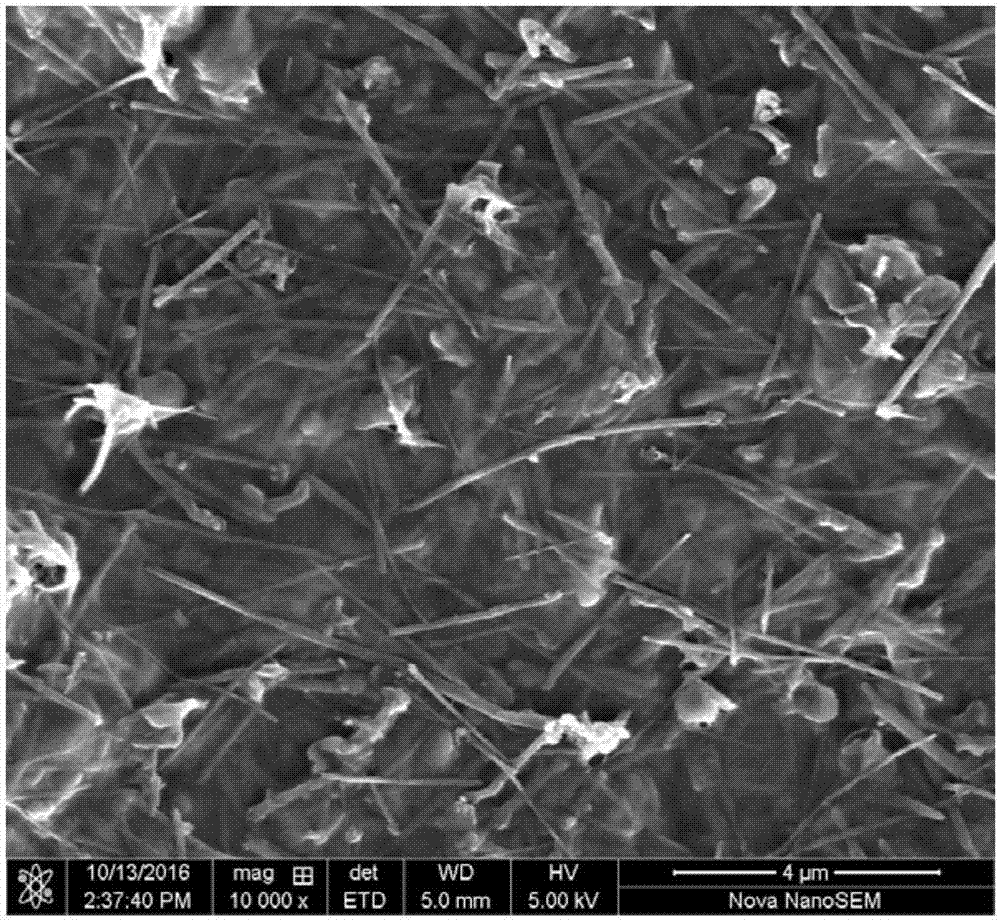

Embodiment 1

[0036] A preparation method of boron nitride nanotube-nanocellulose fiber composite material, the preparation method is to mix 5mg of boron nitride nanotube with 95mL of 1mg / mL nanocellulose fiber aqueous solution, ultrasonic treatment for 3h, under 0.2Pa Vacuum suction filtration, drying the obtained solid at 50° C. for 24 hours to obtain a boron nitride nanotube-nanocellulose fiber composite material.

Embodiment 2

[0038]A preparation method of boron nitride nanotube-nanocellulose fiber composite material, the preparation method is to mix 40mg of boron nitride nanotube with 60mL of 1mg / mL nanocellulose fiber aqueous solution, ultrasonic treatment for 12h, vacuum under 10Pa Filtrate with suction, and dry the obtained solid at 80° C. for 5 hours to obtain a boron nitride nanotube-nanocellulose fiber composite material.

Embodiment 3

[0040] A preparation method of boron nitride nanotube-nanocellulose fiber composite material, the preparation method is to mix 20mg boron nitride nanotube with 800mL of 0.1mg / mL nanocellulose fiber aqueous solution, sonicate for 8h, under 5Pa Vacuum suction filtration, drying the obtained solid at 60° C. for 20 h to obtain a boron nitride nanotube-nanocellulose fiber composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com