Polymer cement-based waterproof coating with photocatalytic function and application of polymer cement-based waterproof coating

A waterproof coating and polymer technology, applied in radiation-absorbing coatings, reflective/signal coatings, coatings, etc., can solve the problem of low tensile strength and bonding strength of the substrate, poor UV aging resistance, lack of UV shielding, etc. Problems, to achieve the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

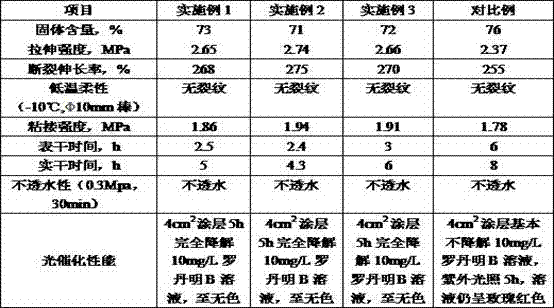

Examples

Embodiment 1

[0032] A polymer cement-based waterproof coating with photocatalytic function, which is composed of an inner coating and an outer coating;

[0033] The inner coating is made from the following raw materials in parts by weight: 45.00 parts of emulsion, 20.00 parts of rapid hardening sulfoaluminate cement, rutile nano-TiO 2 4.00 parts, 12.00 parts of silicon dioxide, 8.00 parts of calcium hydroxide, 0.05 parts of dispersant, 0.30 parts of film-forming aid, 0.10 parts of preservative, 0.50 parts of defoamer, 5.00 parts of water;

[0034] The outer coating is made from the following raw materials in parts by weight: 45.00 parts of emulsion, 20.00 parts of rapid hardening sulfoaluminate cement, anatase nano-TiO 2 2.00 parts, 12.00 parts of silicon dioxide, 8.00 parts of calcium hydroxide, 0.05 parts of dispersant, 0.30 parts of film-forming aid, 0.10 parts of preservative, 0.50 parts of defoamer, and 5.00 parts of water.

[0035] As mentioned, rutile nano-TiO 2 The particle size ...

Embodiment 2

[0047] A polymer cement-based waterproof coating with photocatalytic function, which is composed of an inner coating and an outer coating;

[0048] The inner coating is made from the following raw materials in parts by weight: 50.00 parts of emulsion, 18.00 parts of rapid hardening sulfoaluminate cement, rutile nano-TiO 2 3.00 parts, 15.00 parts of silicon dioxide, 5.00 parts of calcium hydroxide, 0.07 parts of dispersant, 0.2 parts of film-forming aids, 0.08 parts of preservatives, 0.30 parts of defoamers, 6.00 parts of water;

[0049] The outer coating is prepared from the following raw materials in parts by weight: 50.00 parts of emulsion, 18.00 parts of rapid hardening sulfoaluminate cement, anatase nano-TiO 2 1.00 parts, 16.00 parts of silicon dioxide, 5.00 parts of calcium hydroxide, 0.07 parts of dispersant, 0.20 parts of film-forming aid, 0.08 parts of preservative, 0.30 parts of defoamer, 6.00 parts of water.

[0050] As mentioned, rutile nano-TiO 2 The particle siz...

Embodiment 3

[0061] A polymer cement-based waterproof coating with photocatalytic function, which is composed of an inner coating and an outer coating;

[0062] The inner coating is made from the following raw materials in parts by weight: 55.00 parts of emulsion, 15.00 parts of rapid hardening sulfoaluminate cement, rutile nano-TiO 2 1.00 parts, 18.00 parts of silicon dioxide, 2.00 parts of calcium hydroxide, 0.08 parts of dispersant, 0.10 parts of film-forming aid, 0.05 parts of preservative, 0.10 parts of defoamer, 8.00 parts of water;

[0063] The outer coating is made from the following raw materials in parts by weight: 55.00 parts of emulsion, 15.00 parts of rapid hardening sulfoaluminate cement, anatase nano-TiO 2 0.20 parts, 18.00 parts of silicon dioxide, 2.00 parts of calcium hydroxide, 0.08 parts of dispersant, 0.10 parts of film-forming aid, 0.05 parts of preservative, 0.10 parts of defoamer, and 8.00 parts of water.

[0064] As mentioned, rutile nano-TiO 2 The particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com