(V1-xAlx)N/silicon nitride composite coating

A coating and thin-layer technology, applied in the fields of N/Si3N4 nano-multilayer coating and its preparation, ceramic coating and its preparation, can solve the problems of undefined coating friction coefficient and wear performance, and improve it to achieve low Effects of improved friction coefficient, high temperature stability, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

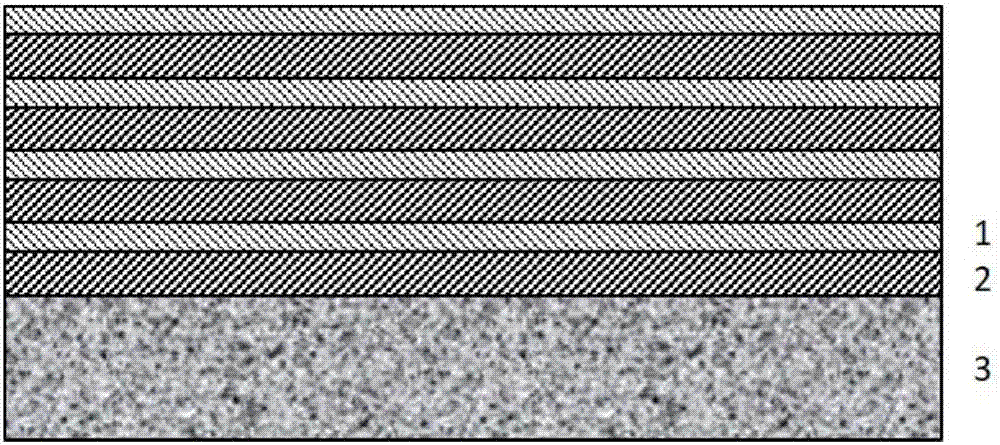

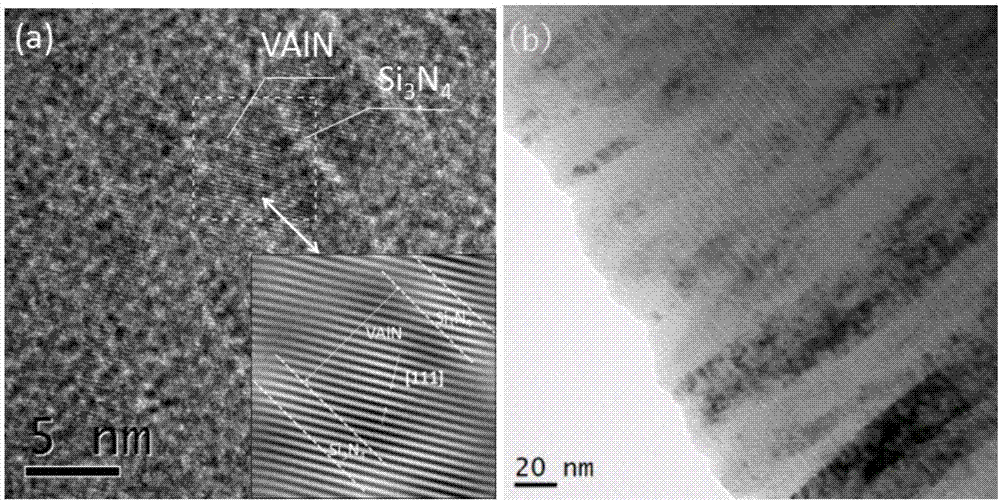

[0039] The present invention (V 0.5 al 0.5 )N / Si 3 N 4 The concrete process parameter of the preparation method of multi-layer coating is: Ar gas partial pressure is 0.7Pa, N 2 The gas partial pressure is 0.3Pa, the V-Al composite target power is radio frequency (RF) 200W, the single deposition time is 10 seconds, the Si target is radio frequency (RF) 50W, the single deposition time is 10 seconds, and the substrate temperature is 300°C , the total deposition time is 120min. The resulting (V 0.5 al 0.5 )N / Si 3 N 4 In each repeated cycle in multilayer coating, (V 0.5 al 0.5 ) The thickness of the N layer is 4nm, Si 3 N 4 The layer thickness is 0.4 nm, the total thickness of the coating is about 2 μm, and the hardness is 43.5 GPa.

Embodiment 2

[0041] The present invention (V 0.5 al 0.5 )N / Si 3 N 4 The concrete process parameter of the preparation method of multi-layer coating is: Ar gas partial pressure is 0.7Pa, N 2 The gas partial pressure is 0.3Pa, the V-Al composite target power is radio frequency (RF) 200W, the single deposition time is 10 seconds, the Si target is radio frequency (RF) 90W, the single deposition time is 10 seconds, and the substrate temperature is 300°C , the total deposition time is 130min. The resulting (V 0.5 al 0.5 )N / Si 3 N 4 In each repeated cycle in multilayer coating, (V 1-x al x ) The thickness of the N layer is 4nm, Si 3 N 4 The layer thickness is 0.7nm, the total thickness of the coating is about 2μm, and the hardness is 31GPa.

Embodiment 3

[0043] The present invention (V 0.5 al 0.5 )N / Si 3 N 4 The concrete process parameter of the preparation method of multi-layer coating is: Ar gas partial pressure is 0.7Pa, N 2 The gas partial pressure is 0.3Pa, the V-Al composite target power is radio frequency (RF) 200W, the single deposition time is 10 seconds, the Si target is radio frequency (RF) 130W, the single deposition time is 10 seconds, and the substrate temperature is 300°C , the total deposition time is 150min. The resulting (V 0.5 al 0.5 )N / Si 3 N 4 In each repeated cycle in multilayer coating, (V 0.5 al 0.5 ) The thickness of the N layer is 4nm, Si 3 N 4 The layer thickness is 2nm, the total coating thickness is about 2μm, and the hardness is 26.4GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com