Polypropylene composite material for supercritical carbon dioxide foaming and preparation method of polypropylene composite material

A technology of carbon dioxide and composite materials, which is applied in the field of polypropylene composite materials and its preparation, can solve the problems of reducing the strength of polypropylene foam materials, unstable dimensions, cell damage, etc., and achieve high foaming efficiency and uniform cell size , the effect of high foam density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

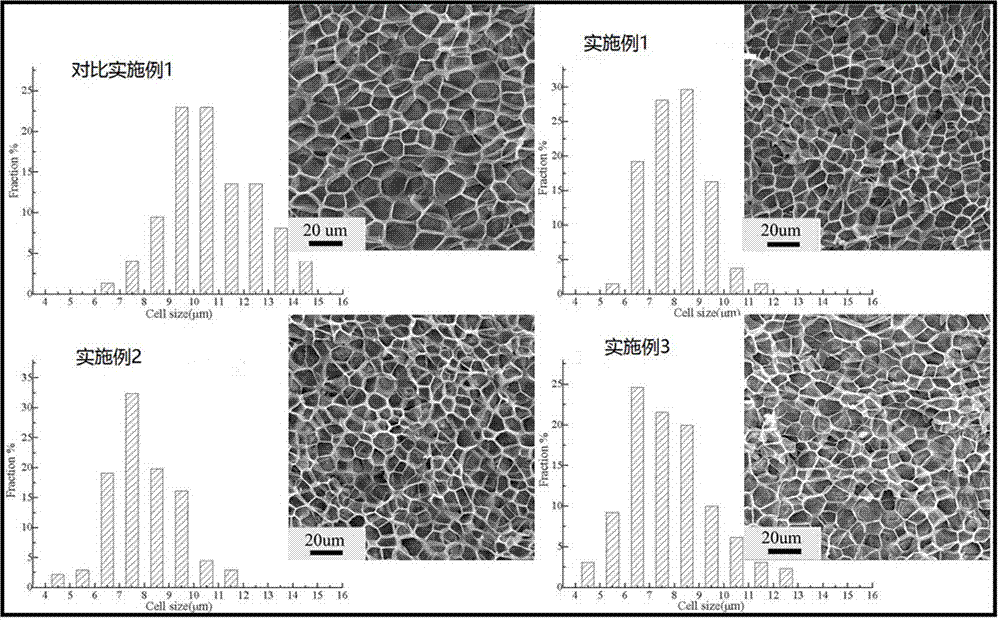

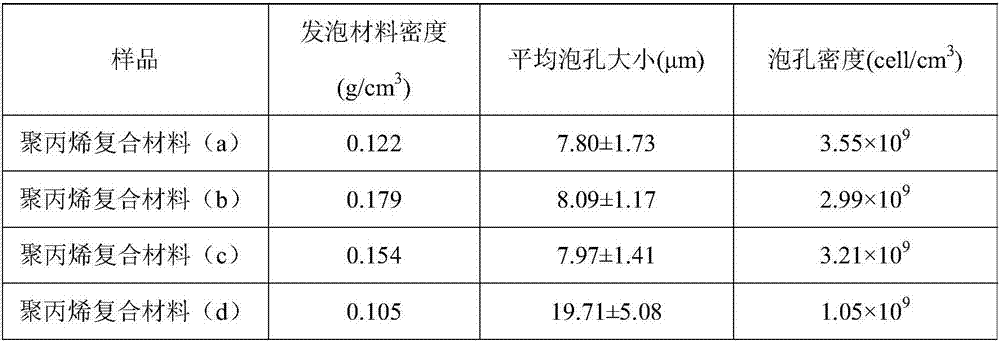

Embodiment 1

[0029] A polypropylene composite material for supercritical carbon dioxide foaming, which consists of the following components by weight: 80% polypropylene, 10% mesoporous nucleating agent (pore size is 10-20nm, particle size is 500nm-1um) , synergistic nucleating agent 10%.

[0030] First, the mesoporous nucleating agent is prepared according to the following steps: Step 1) Stir and blend mesoporous silica, silane coupling agent KH570, and solvent toluene at a mass ratio of 10:1:40, and heat to toluene at 130°C Reflux reaction for 5 hours; step 2) filter the reaction product to remove solvent toluene and impurities, retain the modified mesoporous silica powder, and dry the powder in a vacuum oven at 80°C for 3 hours; step 3) prepare the obtained powder, initiator Azobisisobutylcyanide, CuBr catalyst, and deionized water were stirred and blended for 30 minutes at a mass ratio of 5:1:1:30, and the blend was sintered in a muffle furnace at 300°C for 2 hours to obtain mesoporous ...

Embodiment 2

[0034] A polypropylene composite material for supercritical carbon dioxide foaming, consisting of the following components by weight: 90% polypropylene, 5% mesoporous nucleating agent (pore size 30-50nm, particle size 1um-5um) , synergistic nucleating agent 5%.

[0035]First, prepare the mesoporous nucleating agent according to the following steps: Step 1) Stir and blend mesoporous silica, silane coupling agent KH570, and solvent toluene at a mass ratio of 15:1:45, and heat to toluene at 130°C Reflux reaction for 6 hours; step 2) filter the reaction product to remove solvent toluene and impurities, retain the modified mesoporous silica powder, and dry the powder in a vacuum oven at 90°C for 4 hours; step 3) prepare the obtained powder, initiator Azobisisobutylcyanide, CuBr catalyst, and deionized water were stirred and blended for 30 minutes at a mass ratio of 6:1:1:35, and the blend was sintered in a muffle furnace at 300°C for 2 hours to obtain a mesoporous silica product. ...

Embodiment 3

[0039] A polypropylene composite material for supercritical carbon dioxide foaming, consisting of the following components by weight: 85% polypropylene, 7% mesoporous nucleating agent (pore size 50-100nm, particle size 5um-10um) , synergistic nucleating agent 8%.

[0040] First, the mesoporous nucleating agent is prepared according to the following steps: Step 1) Stir and blend mesoporous silica, silane coupling agent KH570, and solvent toluene at a mass ratio of 14:1:50, and heat to 130°C toluene Reflux reaction for 5 hours; step 2) filter the reaction product to remove solvent toluene and impurities, retain the modified mesoporous silica powder, and dry the powder in a vacuum oven at 70°C for 2 hours; step 3) prepare the obtained powder, initiator Azobisisobutylcyanide, CuBr catalyst, and deionized water were stirred and blended at a mass ratio of 7:1:1:25 for 30 minutes, and the blend was sintered in a muffle furnace at 300°C for 2 hours to obtain the mesoporous silica comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com