Method for simultaneously dephosphorizing and deacidifying grease

An oil and deacidification technology, which is applied in the field of deacidification, simultaneous dephosphorization and deacidification of oil, and simultaneous dephosphorization of oil by using chelating resin, which can solve the problems such as the inability to reuse EDTA, the increase of neutral oil loss, and the poor economy. Reach the effect of remarkable deacidification effect, cost dephosphorization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

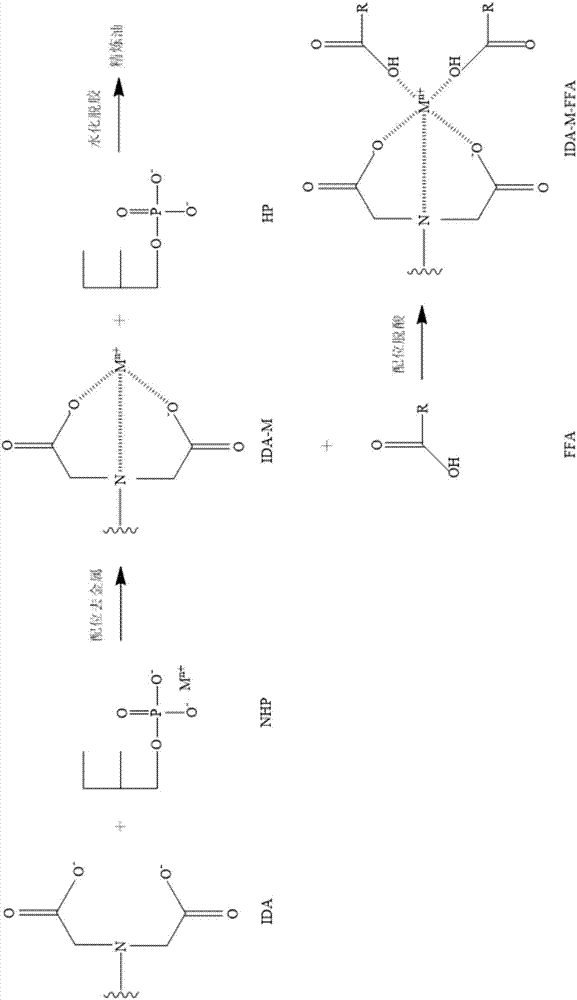

Method used

Image

Examples

Embodiment 1

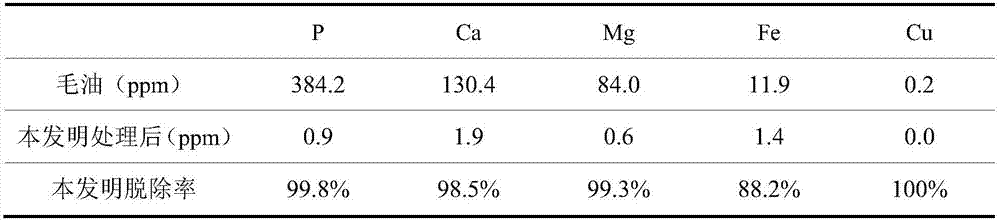

[0052] Chelating resin Amberlite IRC748+ hydration dephosphorization used in rapeseed crude oil dephosphorization and deacidification experiment

[0053] The method used in this embodiment:

[0054] Take 20mL of rapeseed crude oil (phosphorus content: 384.2ppm, acid value: 2.38mg·KOH / g) in a shaker flask, and add 2g of Amberlite IRC748 chelating resin with IDA functional group (Rohm and Haas Company, USA) . Put the shaker into the shaker and shake at a constant temperature of 60°C and 200r / min for 6 hours. Then take out the oil phase, add 80°C, 5% vol demineralized hot water to the oil phase, shake at a constant temperature of 80°C, 200r / min for 30min; then centrifuge at 8000r / min for 20min to obtain refined oil.

[0055] The final phosphorus content after treatment was 0.9 ppm, and the acid value after treatment was 0.08 mg·KOH / g. See Table 1 and Table 4 for specific parameters.

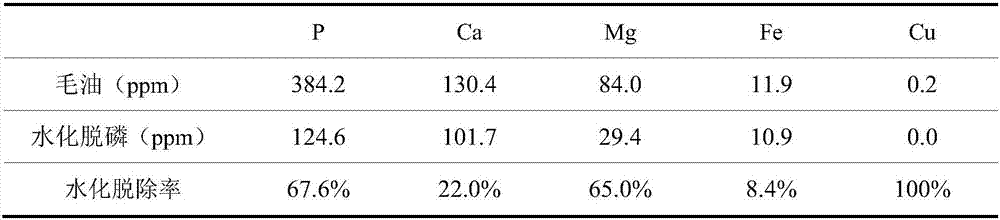

[0056] Hydration and dephosphorization: For comparison, the crude rapeseed oil is directly hydrated an...

Embodiment 2

[0071] Chelating resin Amberlite IRC747+ hydration dephosphorization used in soybean crude oil dephosphorization and deacidification experiment

[0072] The method of the invention:

[0073] Take 20 mL of crude soybean oil (phosphorus content: 126.7 ppm, acid value: 2.16 mg·KOH / g) in a shake flask, and add 1 g of Amberlite IRC747 chelating resin (Rohm and Haas Company, whose functional group is aminophosphonic acid) United States), put the shaker in a shaker and shake at a constant temperature of 60°C and 200r / min for 6h. Then take out the oil phase, add 5% vol, 80°C softened hot water to the oil phase, shake at a constant temperature of 80°C, 200r / min for 30min; then centrifuge at 8000r / min for 20min to obtain refined oil.

[0074] The final phosphorus content after treatment by this method is 0.8 ppm, and the acid value after treatment is 0.39 mg·KOH / g. The specific parameters are shown in Table 5 and Table 8.

[0075] Hydration and dephosphorization: For comparison, the crude soyb...

Embodiment 3

[0088] Chelating resin Amberlite IRC748+ hydration dephosphorization for dephosphorization and deacidification experiment of pepper seed crude oil

[0089] Take 20mL of Amberlite IRC748 resin (Rohm and Haas Company, USA) into the column (column diameter 1cm, column length 25cm), and pump the crude oil (phosphorus content: 233.5ppm, acid value: 21mg·KOH / g) Into the column, the flow rate was 0.3mL / min, and the collection was stopped when the calcium ion leakage concentration at the outlet of the column reached 2ppm, and a total of 4500 mL of pepper seed oil was collected. Take 100 mL of the resin-treated prickly ash seed oil, add 80°C and 5% vol softened hot water, shake at a constant temperature of 80°C and 200 r / min for 30 minutes; then centrifuge at 8000 r / min for 20 minutes to obtain refined oil.

[0090] The final phosphorus content after treatment by this method is 0.5 ppm, and the acid value after treatment is 2.05 mg·KOH / g.

[0091] Regenerate the used resin, the specific proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com