Method for producing maltooligosyl trehalose synthase and maltooligosyl trehalose hydrolase and method for producing trehalose

A technology of trehalose synthase and trehalose hydrolase, which is applied in the fields of bioengineering and enzyme engineering, to achieve the effects of increased yield, high enzyme activity titer, and high cell density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

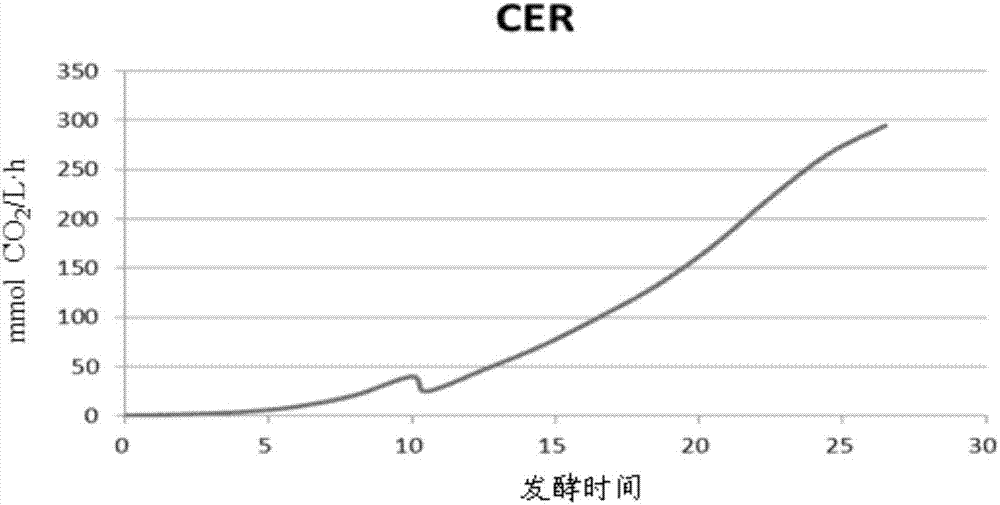

[0059] The method for producing maltooligosaccharide-based trehalose synthase provided in this embodiment comprises the following steps:

[0060] 1.1 Inoculate the transgenic Escherichia coli capable of expressing maltooligosaccharide-based trehalose synthetase into the primary seed shake flask (containing liquid LB medium) according to 1% inoculum amount, place it at 37°C, 220rpm, and culture it on a shaking table for 8h, OD 600 Cultivate to 2.1 to obtain the primary seed activation solution.

[0061] 1.2 Transfer the first-level seed activation liquid to a 15L second-level seed tank (containing LB liquid medium) according to the inoculum amount of 4%, control the reaction temperature at 37°C, DO greater than 10%, pH7.0 (adjusted with 20% ammonia water), and carry out Strain culture, growth 10.5 hours, OD 600 If the value is greater than 4.4, the secondary seed activation solution is obtained.

[0062] Among them, the formula of LB liquid medium: 1% peptone, 0.5% yeast powd...

Embodiment 2

[0073] The method for producing maltooligosaccharyl trehalose hydrolase provided in this example is basically the same as the method in Example 1, except that the transgenic Escherichia coli capable of expressing maltooligosaccharyl trehalose hydrolase is used instead of the expression Transgenic Escherichia coli for maltooligosaccharide-based trehalose synthetase to obtain crude enzyme solution containing maltooligosaccharide-based trehalose hydrolase.

Embodiment 3

[0075] The method for producing trehalose provided in this embodiment comprises the following steps:

[0076] 3.1 Add 9kg of pure starch to the reaction tank (BLBIO-50-FMT, Shanghai Bailun Biotechnology Co., Ltd.), control the pH to 5.5, add 27g of high-temperature amylase, control the temperature at 105°C, and treat for 3.6 hours to liquefy the starch into DE5 % maltodextrin.

[0077] Among them, the activity unit of the high-temperature amylase is 6500U / mL, and the dosage thereof is: 3.0 g of high-temperature amylase corresponds to 1.0 kg of starch.

[0078] 3.2 Maltodextrin Control the temperature at 55°C, use 0.2mol / L phosphoric acid and 0.2mol / L sodium hydroxide to adjust the pH to 6.0, add pullulanase and maltooligosaccharyl trehalose synthase obtained in Example 1 The crude enzyme solution of the maltooligosaccharide-based trehalose hydrolase obtained in Example 2 was treated for 12 hours.

[0079] Among them, the activity unit of pullulanase is 1000-1500U / mL, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com