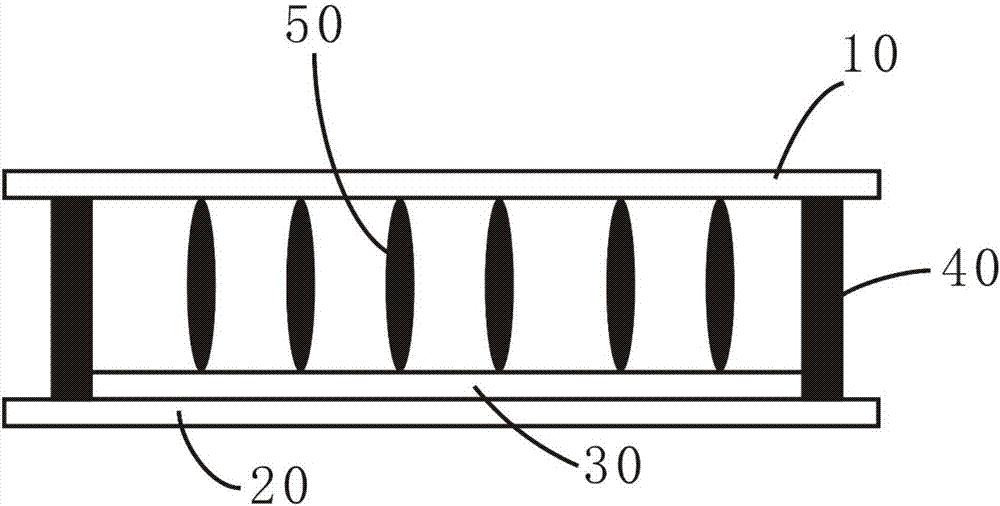

Full-sealed anti-freezing and waterproof heat insulation flat plate type solar heat collector

A solar collector, flat-plate technology, applied in solar collectors, components of solar collectors, solar collectors using working fluid, etc., can solve problems such as easy corrosion and unfavorable application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

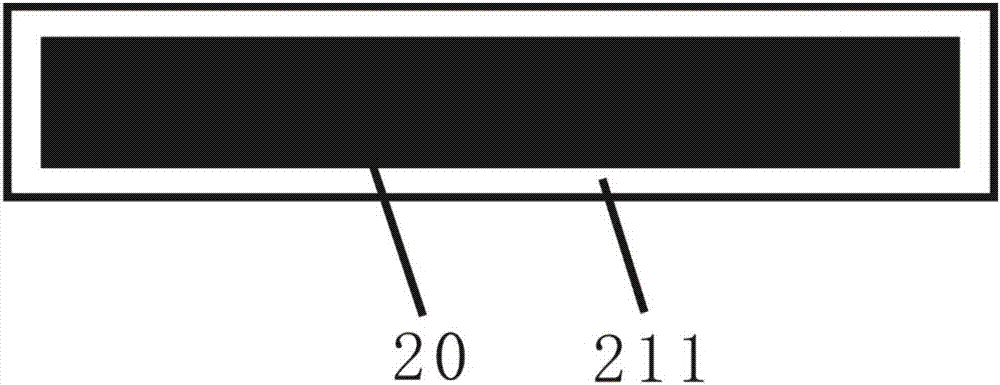

[0026] The preparation process of the antifreeze waterproof layer is:

[0027] Step 1, process the lower substrate: polish the lower substrate with 800-mesh sandpaper for 2 hours, then ultrasonically clean it with acetone, ethanol, and deionized water in sequence, and dry it;

[0028] Step 2, depositing a tungsten film array: coating a layer of photoresist on the surface of the lower substrate, drying, exposing and developing, and then using magnetron sputtering technology to evaporate a layer of tungsten film on the developed photoresist surface, The thickness is 1 μm, and then the photoresist is washed off with acetone, and a tungsten film array is formed on the surface of the lower substrate;

[0029] Step 3, configure the titanium dioxide precursor solution: mix 12.5ml of absolute ethanol, 0.5ml of deionized water and 0.25ml of hydrochloric acid, and then slowly add the mixed solution to 10ml of tetrabutyl titanate and 12.5ml of anhydrous In the mixed solution of ethanol,...

Embodiment 2

[0037] The specific steps are as in Example 1, the difference is that after depositing the tungsten film array and before electrodepositing to prepare the nano-titanium dioxide film, tungsten oxide nanowires are grown by CVD method: the lower substrate after depositing the tungsten film array is put into a tube furnace , using the CVD method to grow tungsten oxide nanowires, the length of the tungsten oxide nanowires is 3 μm;

[0038]After the lower substrate is prepared by the above-mentioned antifreeze and waterproof layer, due to the superhydrophobic performance, it has a good antifreeze and waterproof effect, and has good corrosion resistance and good compactness; for hydrophobicity, when the thickness of the nano-titanium dioxide film is different, the on the lower substrate. The antifreeze waterproof layer exhibits different contact angles, as shown in the following table:

[0039] Thickness of nano-titanium dioxide film / μm contact angle / degree 0 125 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com