Aquaculture decontamination and oxygenation device

An aeration device and aquaculture technology, applied in fish farming, application, animal husbandry, etc., can solve the problems that hinder the sustainable and healthy development of aquaculture, the inability to collect surface and bottom dirt, and short maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

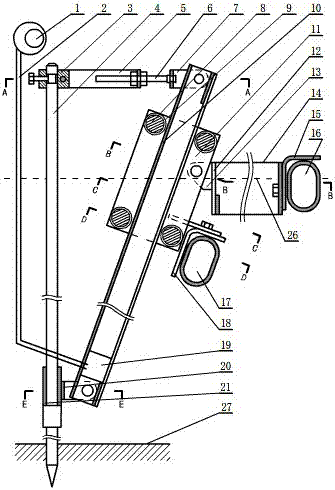

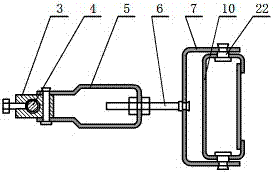

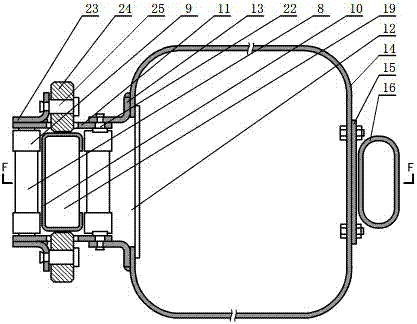

[0020] Embodiments of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0021] See figure 1 In the present invention, except the electric blower 1, the inflation pipe 2, the floating ball 16 of the sewage collection tank, the underwater floating ball 17 and the air stone 19, all the other parts are made of stainless steel, or electroplated copper, nickel plated or electroplated after metal materials are selected for use. Galvanized etc.

[0022] The electric blower 1 of the present invention selects the Roots blower and places it outside the pond. The motor of the Roots blower 1 can be controlled by frequency conversion. Oxygen and upward airflow are produced. The inflatable pipe 2 is made of polyethylene soft plastic pipe, and its function is to transmit gas. A rotary air control valve can be installed on the inflatable pipe 2. The air flow speed can be adjusted by rotating the air control valve. The fixed pole 4 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com