Preparation method of black Bi4Ti3O12 photocatalyst

A photocatalyst, black technology, applied in the field of black Bi4Ti3O12 photocatalyst prepared by solvothermal method, can solve the problems of high cost, complicated operation steps, time-consuming, etc., and achieve the effect of high crystallinity, simple process and process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 0.34g of bismuth oxide and 0.087g of titanium dioxide in a mortar, grind them evenly, place the obtained light yellow powder in a quartz boat, calcinate at 800°C for 2h, cool to room temperature, wash and dry the product to obtain white titanium bismuth acid. Disperse the obtained white bismuth titanate powder in ethanol solution, stir evenly, transfer it to a hydrothermal kettle, and put it in an oven at 180°C for 12 hours of reaction. After cooling to room temperature, it is centrifugally washed and dried to obtain black bismuth titanate.

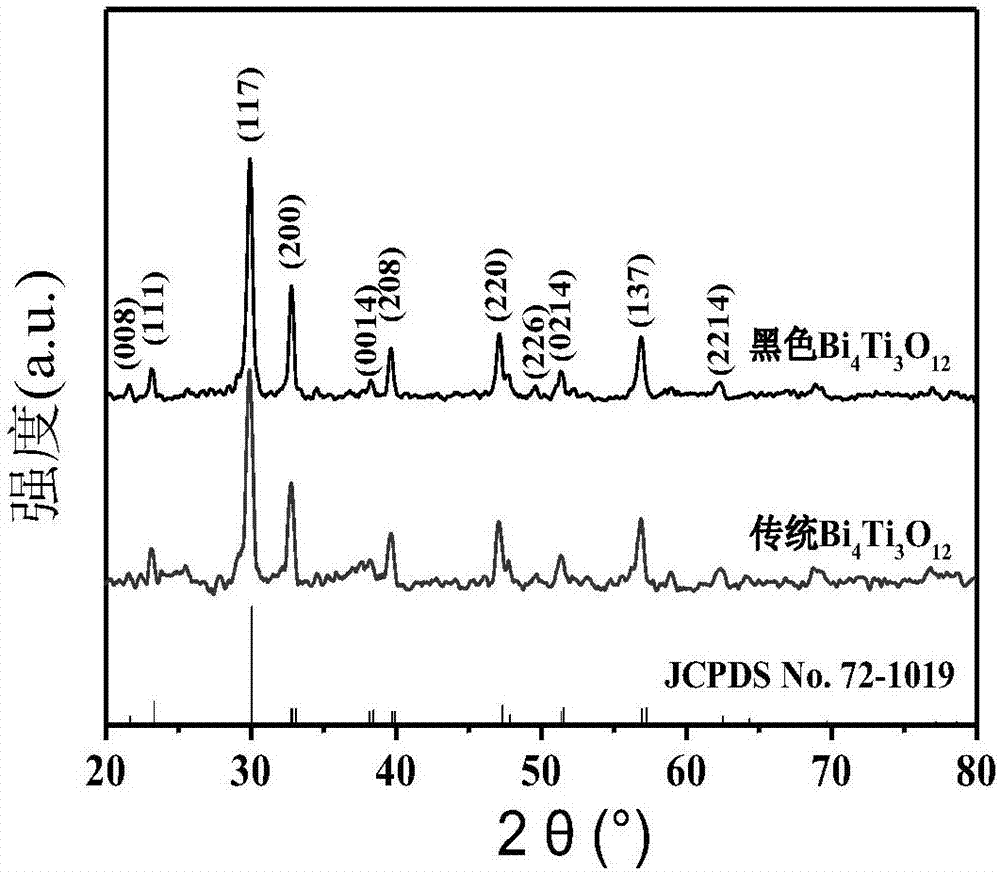

[0024] figure 1 The XRD diffraction pattern of the prepared sample, the peaks at each position in the figure belong to bismuth titanate, and no other impurity peaks appear. Compared with the standard JCPDS card (21-1272), it can be determined that it is Bi with good crystallinity. 4 Ti 3 o 12 Powder.

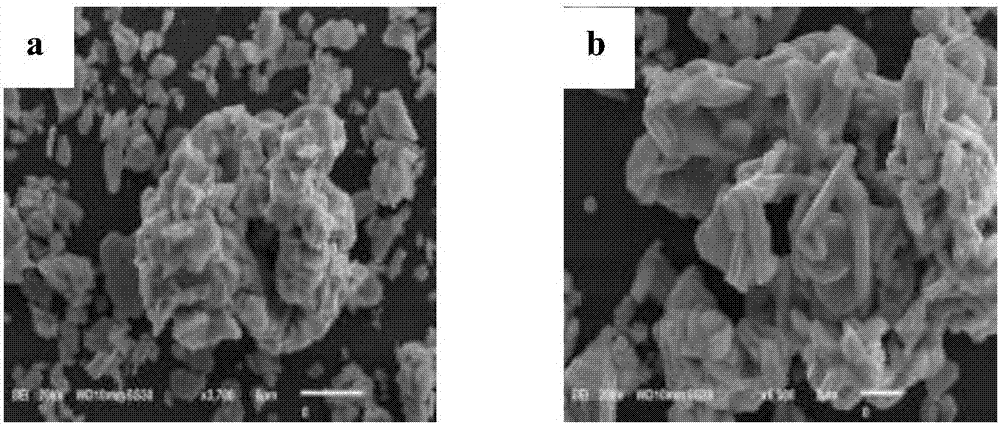

[0025] figure 2 As a scanning electron microscope photo, it can be seen from the figure that it is different from the t...

Embodiment 2

[0029] Weigh 0.34g of bismuth oxide and 0.022g of titanium dioxide in a mortar, grind evenly, place the obtained light yellow powder in a quartz boat, calcinate at 800°C for 2h, cool to room temperature, wash and dry the product to obtain white titanium bismuth acid. Disperse the obtained white bismuth titanate powder in the ethanol solution, stir evenly, transfer it to a hydrothermal kettle, put it in an oven at 140°C for 10 hours, and after cooling to room temperature, wash it with centrifugal water and dry it.

Embodiment 3

[0031]Weigh 0.34g of bismuth oxide and 0.043g of titanium dioxide in a mortar, grind them evenly, place the obtained light yellow powder in a quartz boat, calcinate at 500°C for 0.5h, cool to room temperature, wash and dry the product to obtain a white Bismuth titanate. Disperse the obtained white bismuth titanate powder in ethanol solution, stir evenly, transfer it to a hydrothermal kettle, put it in an oven at 140°C for 10 hours, and after cooling to room temperature, wash it with centrifugal water and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com