Method for improving strength of superlight foamed ceramic body

A technology of foam ceramics and ceramic powder, which is applied in the field of enhancing the strength of ultra-light foam ceramic bodies, can solve the problems of weakening the strength of foam ceramics and stability in use, and achieves the effects of low production cost, good processability, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Prepare alumina slurry with a mass fraction of 20%, and use a roller mill to mill for 2 hours. The average particle size of the alumina ceramic powder is 0.41 μm.

[0024] (2) Add 0.05wt% sodium lauryl sulfate and 1.0wt% polyvinyl alcohol to the slurry after ball milling to adjust the pH value of the slurry to 4.5.

[0025] (3) The slurry was then mechanically stirred at a rotational speed of 1800rmp for 10min for foaming to obtain a particle-stabilized foam.

[0026] (4) Immediately freeze the resulting foam slurry at -10°C for 20 hours after foaming, and then thaw at 10°C for 6 hours. Repeat the freeze-thaw process 2 times.

[0027] (5) The dried ceramic foam body was heated to 1550° C. at a heating rate of 3° C. / min, and then kept for 2 hours.

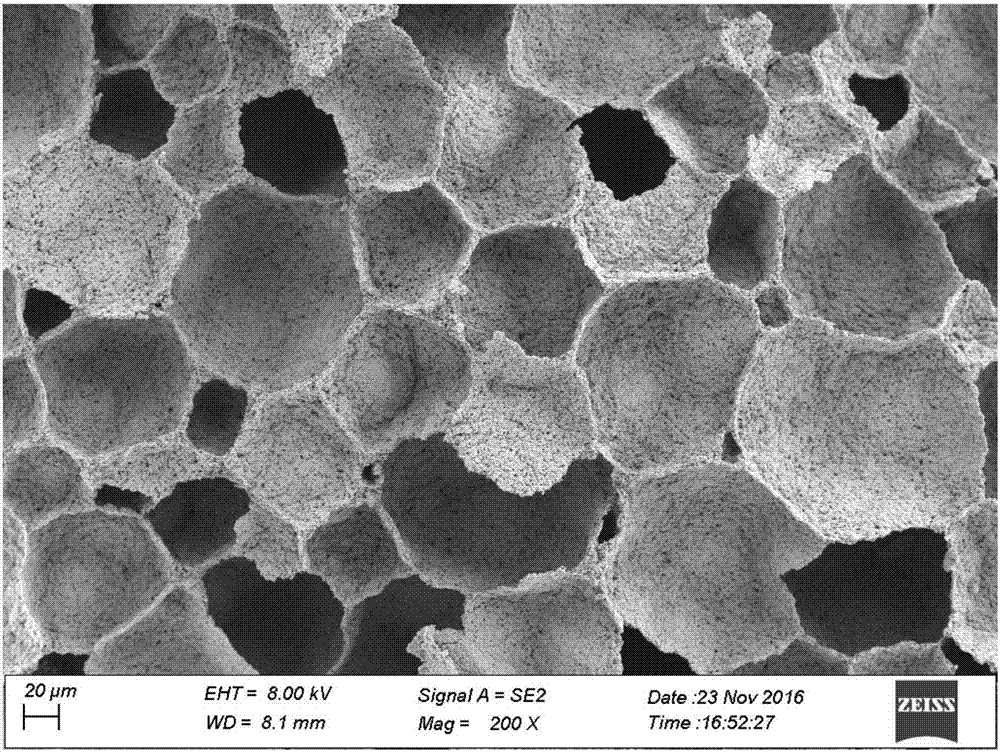

[0028] The prepared alumina foam body is as figure 1 As shown in the macroscopic photo of the alumina foam body, the porosity is 97.1%, and the microscopic appearance of the foam body is as follows: figure 2 shown. ...

Embodiment 2

[0030] (1) Prepare a zirconia slurry with a mass fraction of 30%, and use a roller mill to mill for 4 hours. The average particle size of the zirconia ceramic powder is 0.76 μm.

[0031] (2) Add 0.06wt% cetyl sodium sulfate and 1.2wt% polyvinyl alcohol relative to the mass of the slurry to the slurry after ball milling to adjust the pH value of the slurry to 5.1.

[0032] (3) The slurry was then mechanically stirred at a rotational speed of 1600rmp for 15min for foaming to obtain a particle-stabilized foam.

[0033] (4) Immediately freeze the resulting foam slurry at -10°C for 24 hours after foaming, and then thaw at 10°C for 4 hours. Repeat the freeze-thaw process 3 times.

[0034] (5) The dried ceramic foam body was heated to 1400° C. at a heating rate of 3° C. / min, and then kept for 2 hours.

[0035] The porosity of the prepared zirconia foam body was 95.9%, and the porosity of the zirconia foam ceramics prepared after sintering was 93.4%.

Embodiment 3

[0037] (1) Prepare a kyanite slurry with a mass fraction of 30%, and use a roller ball mill to mill for 5 hours. The average particle size of the kyanite powder is 0.98 μm.

[0038] (2) Add 0.05wt% sodium lauryl sulfate and 0.8wt% polyvinyl alcohol relative to the mass of the slurry to the slurry after ball milling, and adjust the pH value of the slurry to 6.0.

[0039] (3) The slurry was then mechanically stirred at a rotational speed of 1800rmp for 10min for foaming to obtain a particle-stabilized foam.

[0040] (4) Immediately freeze the resulting foam slurry at -10°C for 24 hours after foaming, and then thaw at 10°C for 3 hours. Repeat the freeze-thaw process 3 times.

[0041](5) The dried ceramic foam body was heated to 1450° C. at a heating rate of 3° C. / min, and then kept for 2 hours.

[0042] The porosity of the prepared kyanite foam body is 94.8%, and the porosity of the foam ceramics prepared after sintering is 92.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com