Ultraviolet curing matte coating gloss oil with high pollution resistance

A high anti-ultraviolet technology, applied in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the problems of not having high anti-fouling performance, not reaching matte, etc., to improve dirt resistance Effects of improving performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

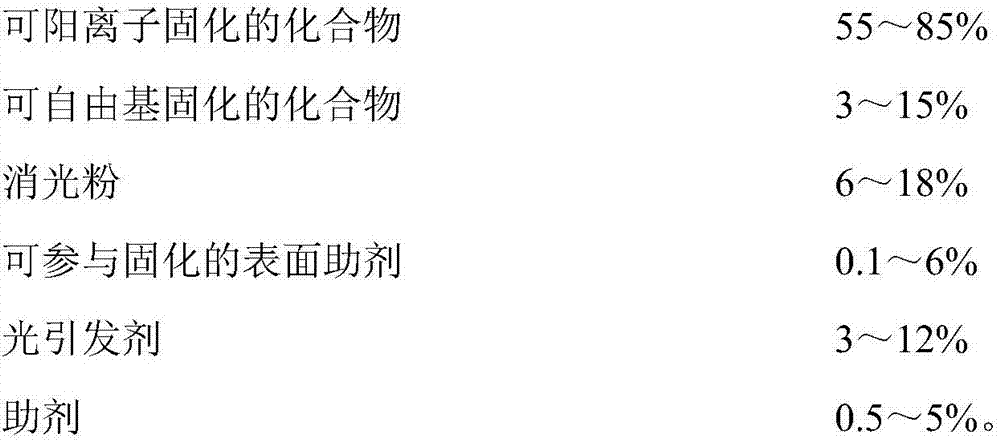

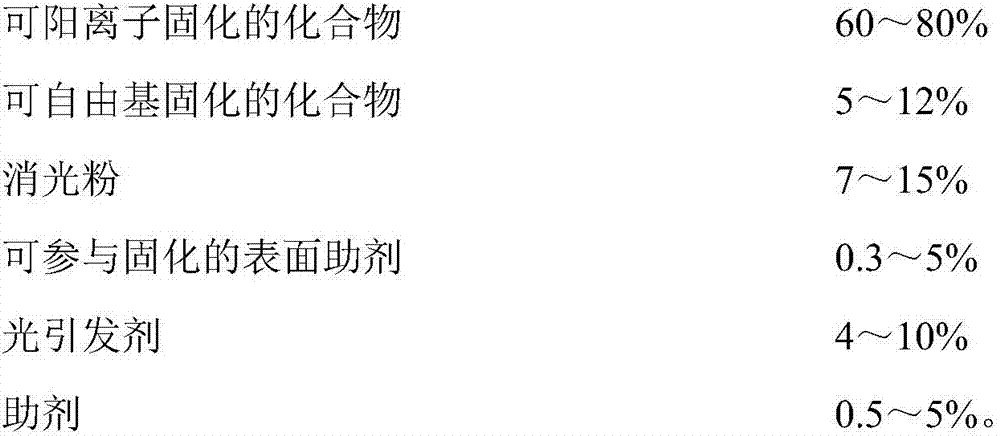

Method used

Image

Examples

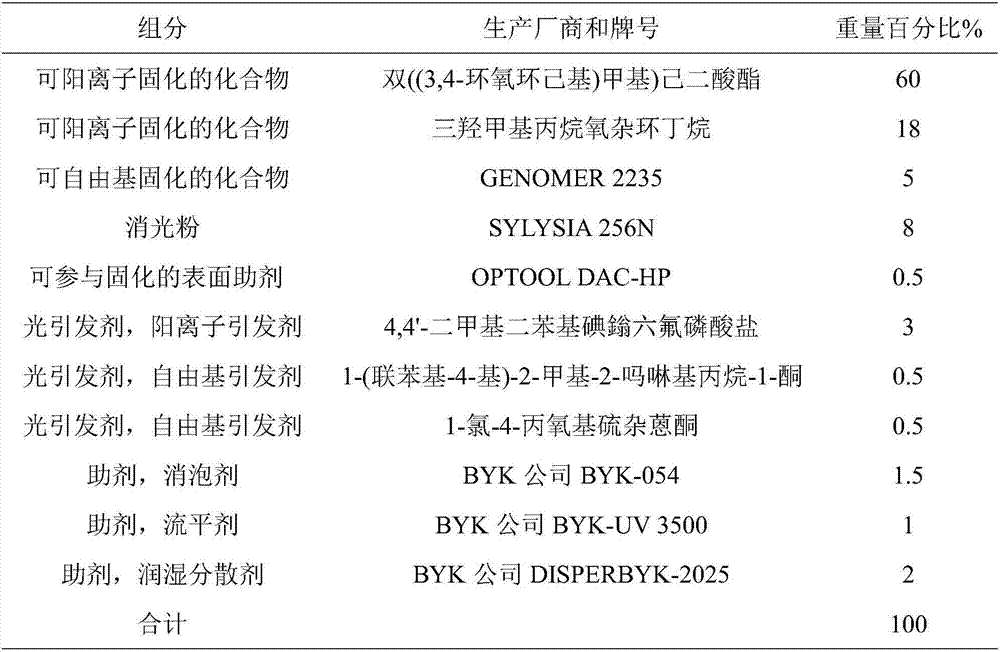

Embodiment 1

[0021] The compound that can be cured by free radicals is aliphatic epoxy acrylate, the product of RAHN's brand is GENOMER 2235; the matting powder is precipitated silica with organic surface treatment, and the product of Fuji's brand is SYLYSIA 256N; the surface that can participate in curing The auxiliary agent is UV-curable acrylate-modified perfluoropolyether, the product of Daikin Fluorochemical Co., Ltd. with the brand name OPTOOLDAC-HP; the defoamer is organically modified polysiloxane, the product of BYK Company’s brand name is BYK-054; The leveling agent is polyether-modified polysiloxane, BYK’s brand is BYK-UV 3500; the wetting and dispersing agent is polymer copolymer, BYK’s brand is DISPERBYK-2025.

[0022] The formula is shown in Table 1:

[0023] Table 1

[0024]

[0025] Preparation method: Mix all raw materials, fully stir and disperse to obtain the high antifouling matte coating varnish. The viscosity of DIN4 cup at 25°C is 58s, which is suitable for coati...

Embodiment 2

[0028] The compound that can be cured by free radicals is polyether acrylate, and the product of IGM company is Photomer 5662; the matting powder is precipitated silica treated with a special organic polymer, and the product of Evonik is ACEMATT3600; the product that can participate in curing The surface additive is silicone acrylate, Evonik’s brand is TEGO Rad 2800; the defoamer is fluorosilicone solution, Evonik’s brand is TEGO Airex 931; the leveling agent is organically modified polysilicon Oxane, Evonik's brand is TEGO Glide 420; the wetting and dispersing agent is modified polyether, Evonik's brand is TEGO Dispers 650.

[0029] The formula is shown in Table 2:

[0030] Table 2

[0031]

[0032]

[0033] Preparation method: Mix all the raw materials, fully stir and disperse to obtain the high antifouling matte coating varnish. The viscosity of DIN4 cup at 25°C is 75s, which is suitable for coating on the surface of plastic substrates.

[0034] The front glossiness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com