Pre-coating film

A technology of pre-coating film and substrate layer, which is applied in the direction of coating, film/sheet release coating, film/sheet-shaped adhesive, etc., which can solve the problem of insufficient bonding fastness between printed matter and pre-coating film Problems such as shedding of film-covered articles and high hot-melt temperature of hot-melt adhesives can achieve the effect of improving bonding durability, increasing service life, and uniform curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

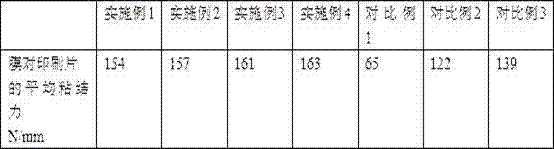

Examples

Embodiment 1

[0022] A kind of pre-coating film, comprises the substrate layer that thickness is 0.01mm and the hot-melt adhesive layer that is coated on the substrate layer, and substrate layer is linear low-density polyethylene, between substrate layer and hot-melt adhesive layer A functional layer is provided, and the functional layer is formed by coating an aqueous solution of a functional composition with a mass fraction of 3%. 5 parts, 5 parts of sodium citrate, 3 parts of hydrolyzed polymaleic anhydride and 0.5 parts of disodium hydrogen phosphate, and then configure 3% aqueous solution with each part of 5g, and coat it on the substrate layer.

[0023] Then configure the hot-melt adhesive used for the hot-melt adhesive layer according to the following component distribution: ethylene-vinyl acetate copolymer 100g, vinyl acetate-vinyl chloride 5g, ethyl cellulose 2g, polyethyleneimine 8g, pentaerythritol stearate 1g , 3g of water-based polyurethane and 1g of hydroxypropyl-terminated fl...

Embodiment 2

[0025] A kind of pre-coating film, comprises the substrate layer that thickness is 0.03mm and the hot-melt adhesive layer that is coated on the substrate layer, and substrate layer is polypropylene, is provided with function between substrate layer and hot-melt adhesive layer layer, and the functional layer is formed by coating an aqueous solution of a functional composition with a mass fraction of 5%. 7 parts of sodium bicarbonate, 1 part of hydrolyzed polymaleic anhydride, and 1 part of disodium hydrogen phosphate, and then 5g of each part was configured into a 3% aqueous solution and coated on the substrate layer.

[0026] Then configure the hot-melt adhesive used for the hot-melt adhesive layer according to the following component distribution ratio: ethylene-vinyl acetate copolymer 100g, vinyl acetate-vinyl chloride 10g, ethyl cellulose 3g, polyethyleneimine 5g, pentaerythritol stearate 3g , 5 g of water-based polyurethane and 0.5 g of hydroxypropyl-terminated fluoropolys...

Embodiment 3

[0028] On the basis of the formula of the functional composition in Example 1, 0.2 parts of ammonium chloride were added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com